Jun . 28, 2024 12:20 Back to list

Manufacturers of Galvanized Steel Wire Products Top Factories and Their Services

The Significance of Galvanized Steel Wire Factories in Modern Industry

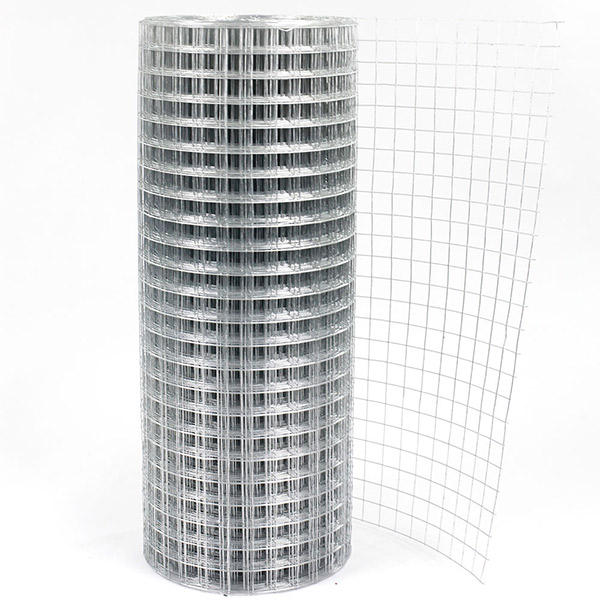

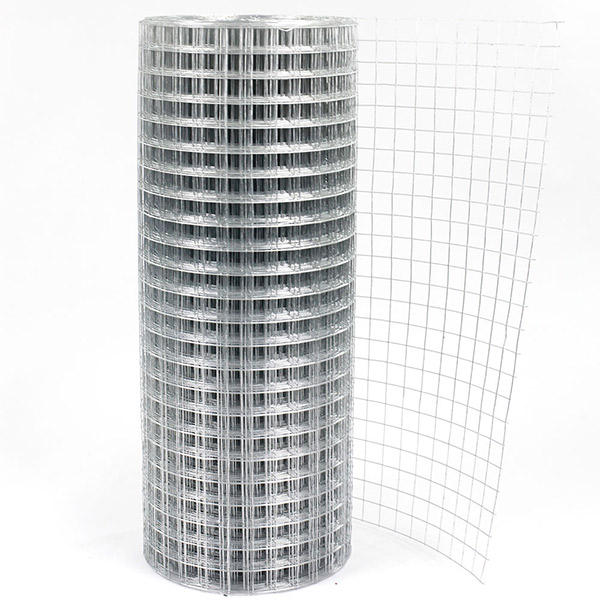

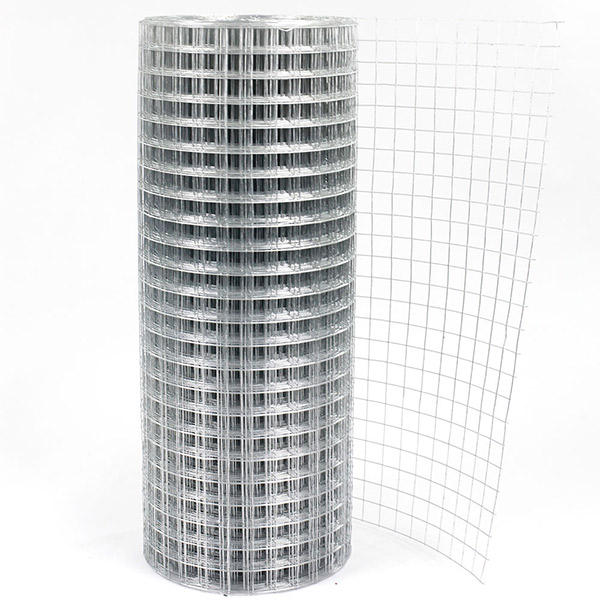

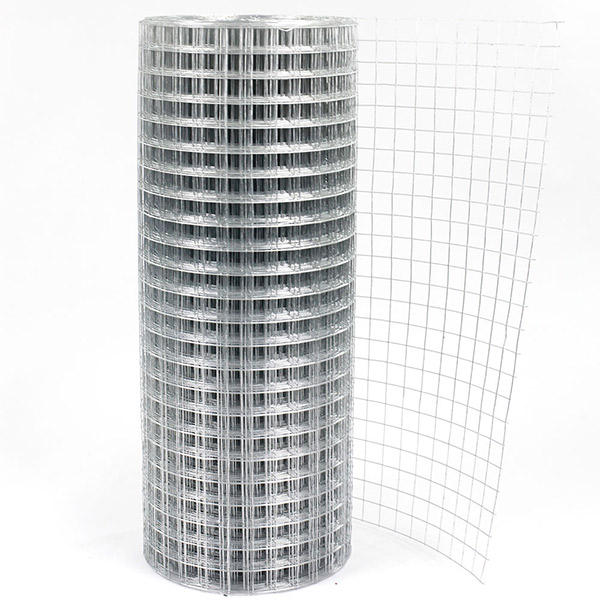

Galvanized steel wire, a testament to modern industrial ingenuity, has revolutionized construction, agriculture, and numerous other sectors with its durability and corrosion resistance. At the heart of this transformation lie the galvanized steel wire factories, which have not only streamlined production processes but also elevated quality standards across various industries.

The process of manufacturing galvanized steel wire begins with high-quality carbon steel, which is then drawn through a series of dies to achieve the desired wire thickness and strength. This wire is subsequently cleaned to remove any surface impurities and then dipped into a bath of molten zinc. The zinc coating protects the steel from rust and corrosion, thereby extending the lifespan of the wire significantly.

Galvanized steel wire factories play a pivotal role in ensuring that this process is executed with precision and efficiency. State-of-the-art technology enables these facilities to maintain consistent quality and minimize waste. Automation in these factories allows for high-speed production without compromising on the integrity of the final product. Additionally, stringent quality control measures guarantee that every strand of wire meets international standards before it leaves the factory.

The impact of these factories extends beyond their production capabilities

The impact of these factories extends beyond their production capabilities The impact of these factories extends beyond their production capabilities

The impact of these factories extends beyond their production capabilities

The impact of these factories extends beyond their production capabilities

The impact of these factories extends beyond their production capabilities galvanized steel wire factories. They often serve as hubs for innovation, where research and development teams work tirelessly to improve existing methodologies and explore new applications for galvanized steel wire. As a result, we see continuous advancements in wire designs tailored for specific uses, such as heavy-duty wires for construction or specially coated variants for marine environments.

Environmental considerations are also paramount in contemporary galvanized steel wire factories. Many have adopted sustainable practices, including the use of recycled materials and energy-efficient production methods. These efforts reduce the ecological footprint of the industry while maintaining its core function of supplying robust and reliable materials.

In conclusion, galvanized steel wire factories stand at the forefront of industrial progress, driving innovation, ensuring quality, and promoting sustainability. Their influence permeates through various sectors, enhancing the strength and longevity of structures and products worldwide. As we look towards the future, these factories will undoubtedly continue to adapt and evolve, shaping the landscape of modern industry for years to come.

galvanized steel wire factories. They often serve as hubs for innovation, where research and development teams work tirelessly to improve existing methodologies and explore new applications for galvanized steel wire. As a result, we see continuous advancements in wire designs tailored for specific uses, such as heavy-duty wires for construction or specially coated variants for marine environments.

Environmental considerations are also paramount in contemporary galvanized steel wire factories. Many have adopted sustainable practices, including the use of recycled materials and energy-efficient production methods. These efforts reduce the ecological footprint of the industry while maintaining its core function of supplying robust and reliable materials.

In conclusion, galvanized steel wire factories stand at the forefront of industrial progress, driving innovation, ensuring quality, and promoting sustainability. Their influence permeates through various sectors, enhancing the strength and longevity of structures and products worldwide. As we look towards the future, these factories will undoubtedly continue to adapt and evolve, shaping the landscape of modern industry for years to come.

The impact of these factories extends beyond their production capabilities

The impact of these factories extends beyond their production capabilities

The impact of these factories extends beyond their production capabilities

The impact of these factories extends beyond their production capabilities galvanized steel wire factories. They often serve as hubs for innovation, where research and development teams work tirelessly to improve existing methodologies and explore new applications for galvanized steel wire. As a result, we see continuous advancements in wire designs tailored for specific uses, such as heavy-duty wires for construction or specially coated variants for marine environments.

Environmental considerations are also paramount in contemporary galvanized steel wire factories. Many have adopted sustainable practices, including the use of recycled materials and energy-efficient production methods. These efforts reduce the ecological footprint of the industry while maintaining its core function of supplying robust and reliable materials.

In conclusion, galvanized steel wire factories stand at the forefront of industrial progress, driving innovation, ensuring quality, and promoting sustainability. Their influence permeates through various sectors, enhancing the strength and longevity of structures and products worldwide. As we look towards the future, these factories will undoubtedly continue to adapt and evolve, shaping the landscape of modern industry for years to come.

galvanized steel wire factories. They often serve as hubs for innovation, where research and development teams work tirelessly to improve existing methodologies and explore new applications for galvanized steel wire. As a result, we see continuous advancements in wire designs tailored for specific uses, such as heavy-duty wires for construction or specially coated variants for marine environments.

Environmental considerations are also paramount in contemporary galvanized steel wire factories. Many have adopted sustainable practices, including the use of recycled materials and energy-efficient production methods. These efforts reduce the ecological footprint of the industry while maintaining its core function of supplying robust and reliable materials.

In conclusion, galvanized steel wire factories stand at the forefront of industrial progress, driving innovation, ensuring quality, and promoting sustainability. Their influence permeates through various sectors, enhancing the strength and longevity of structures and products worldwide. As we look towards the future, these factories will undoubtedly continue to adapt and evolve, shaping the landscape of modern industry for years to come. Latest news

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025