Nov . 15, 2024 20:04 Back to list

low carbon cold drawn steel wire 3mm supplier

Low Carbon Cold Drawn Steel Wire A Comprehensive Overview

Low carbon cold drawn steel wire has garnered significant attention in various industries due to its versatility and beneficial properties. This article delves into the characteristics, manufacturing process, applications, and advantages of low carbon cold drawn steel wire, along with insights into sourcing it from reliable suppliers.

Understanding Low Carbon Cold Drawn Steel Wire

Low carbon steel is defined by its carbon content, typically ranging from 0.05% to 0.25%. The term “cold drawn” refers to a manufacturing process in which the wire is pulled through a die to reduce its diameter while increasing its strength. This process occurs at room temperature, which helps enhance the physical properties of the steel, including its tensile strength and surface finish.

In comparison to high carbon or other alloy steels, low carbon steel is more ductile and malleable. This makes it easier to work with and allows for more intricate applications across various fields.

Manufacturing Process

The production of low carbon cold drawn steel wire begins with the selection of high-quality steel billets or rods. These raw materials are first heated and then drawn through a series of progressively smaller dies. The cold drawing process not only reduces the diameter of the wire but also aligns the crystalline structure of the steel, resulting in improved mechanical properties.

After the drawing process, the wire is typically subjected to additional treatments such as annealing, which involves heating and cooling processes that relieve internal stresses and enhance ductility. The wire may also undergo processes such as galvanization for corrosion resistance or coating to ensure that it meets specific application requirements.

Applications of Low Carbon Cold Drawn Steel Wire

Low carbon cold drawn steel wire is widely used across various industries, including

1. Construction It is commonly employed in the manufacturing of reinforced concrete, wire ropes, and mesh. The wire's strength and flexibility make it ideal for structural applications. 2. Automotive Industry Low carbon wire is used to produce components such as spring wires, which require high tensile strength and ductility. 3. Manufacturing The wire serves as a key material in the production of various fasteners, such as bolts, screws, and rivets.

4. Furniture Industry It is used for making wire frames and springs, contributing to the durability and comfort of furniture pieces.

5. Electronics Due to its electrical conductivity properties, low carbon steel wire is also used in various electronic applications, including connectors and wiring.

Advantages of Low Carbon Cold Drawn Steel Wire

low carbon cold drawn steel wire 3mm supplier

The popularity of low carbon cold drawn steel wire can be attributed to several inherent advantages

- Enhanced Strength The cold drawing process increases the yield strength of the wire, making it suitable for demanding applications.

- Improved Ductility Despite its strength, low carbon steel remains ductile, allowing for bending and shaping without breaking.

- Cost-Effectiveness Low carbon steel is generally more affordable than other alloys, making it an economical choice for manufacturers.

- Versatile Applications Due to its property variations, it can be utilized in a broad range of applications across multiple industries.

- Ease of Fabrication The malleability of low carbon steel wire allows for easy fabrication into various shapes and forms.

Sourcing Low Carbon Cold Drawn Steel Wire

When looking for a supplier of low carbon cold drawn steel wire, it is vital to consider several factors to ensure quality and reliability. Here are some tips for sourcing

1. Quality Certifications Check if the supplier has relevant quality certifications, such as ISO or ASTM, which indicate adherence to international standards.

2. Reputation and Experience Look for suppliers with a proven track record in the industry. Read customer reviews and testimonials to gauge their reliability.

3. Customization Some projects may require specific sizes or coatings. Ensure that the supplier can accommodate custom orders.

4. Pricing While cost is important, make sure that you are not compromising on quality. Compare prices between suppliers to find a fair value.

5. Delivery and Support Reliable suppliers should offer timely deliveries and customer support for any queries or issues you might encounter.

In conclusion, low carbon cold drawn steel wire stands out as a valuable material in numerous applications due to its excellent strength-to-weight ratio and versatility. By sourcing from reputable suppliers, businesses can leverage its properties to enhance their products and maintain competitive advantages in their respective markets.

-

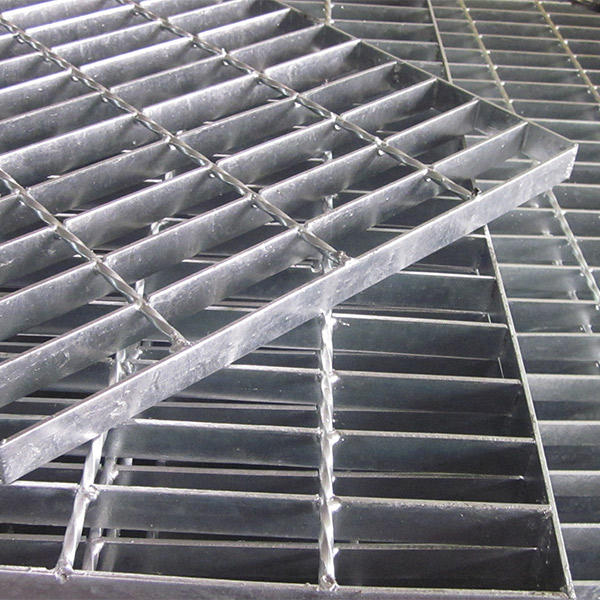

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025