Nov . 05, 2024 12:01 Back to list

iron square bar manufacturers

The Role of Iron Square Bar Manufacturers in the Construction and Manufacturing Industries

Iron square bars are vital components in various industries, particularly in construction and manufacturing. They offer structural strength and versatility, making them an essential material in various applications such as heavy machinery, framework, fencing, and more. With the increasing demand for durable and reliable materials, iron square bar manufacturers play a crucial role in ensuring that quality products are available to meet the needs of various sectors.

Understanding Iron Square Bars

Iron square bars are solid bars with a square cross-section, predominantly made from iron or steel. They can be produced in different sizes and grades, thus catering to diverse industrial requirements. Their robust structure makes them suitable for a range of applications, from reinforcing concrete structures to serving as base materials for components in machinery.

One of the primary reasons these bars are favored is their strength-to-weight ratio. Iron is inherently strong, and when shaped into a square bar, it can bear significant loads without bending or breaking. This characteristic is particularly valued in construction projects where safety and durability are paramount.

The Manufacturing Process

The manufacturing of iron square bars involves several key steps

1. Raw Material Sourcing The process begins with acquiring high-quality raw materials, typically iron ore or steel scrap. The choice of material greatly influences the final product's strength and performance.

2. Melting and Refining The raw materials are melted in a furnace, where impurities are removed. This refining process ensures that only the best-quality metal is used, thus improving the overall performance of the square bars.

3. Casting Once the metal is refined, it is poured into molds to form billets, which are then cooled and solidified.

4. Rolling The solidified billets are subjected to hot or cold rolling processes to achieve the desired dimensions. Rolling not only shapes the bars but also enhances their structural integrity through work hardening.

iron square bar manufacturers

5. Cutting and Finishing After rolling, the bars are cut to the required lengths. Further finishing processes, such as grinding or polishing, may be applied to ensure the bars meet specific industry standards.

Quality Assurance and Standards

Quality assurance is paramount in the manufacturing of iron square bars. Manufacturers need to adhere to stringent international standards and regulations to ensure their products are safe and reliable. Quality checks occur at various stages of the production process, from raw material inspection to final product testing.

Many manufacturers also invest in advanced technological solutions to enhance quality control. This includes the use of automated machinery and real-time monitoring systems that help maintain consistency and precision in production.

The Market Demand

The demand for iron square bars is driven by several factors, including urbanization, industrial growth, and infrastructure development. As cities expand and new construction projects arise, the need for reliable construction materials escalates. Furthermore, the manufacturing sector's continuous evolution prompts a demand for stronger components to support advanced machinery and equipment.

Iron square bar manufacturers are thus positioned strategically within the supply chain, catering to a wide variety of clients that include construction firms, manufacturers, and even retailers. The competitive landscape also encourages manufacturers to innovate and improve their offerings continuously.

Challenges and Future Prospects

Despite the robust demand, iron square bar manufacturers encounter several challenges, such as fluctuations in raw material prices and growing environmental regulations. The industry is moving towards adopting more sustainable practices, including recycling scrap metal and utilizing more eco-friendly production methods.

In conclusion, iron square bar manufacturers play an essential role in various industries, providing a crucial material that supports the backbone of modern construction and manufacturing. Moving forward, these manufacturers will need to adapt to changing market dynamics and embrace innovation while ensuring sustainability in their operations. The future of this sector looks promising, with advancements in technology and a growing emphasis on quality materials paving the way for new possibilities.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

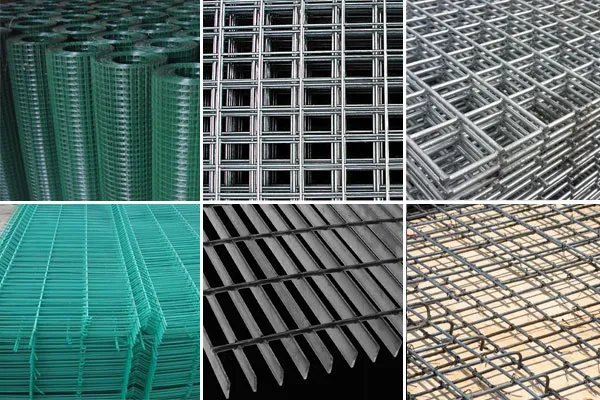

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025