Nov . 27, 2024 01:59 Back to list

Manufacturers of Iron Square Bars for Various Industrial Applications and Projects

Understanding Iron Square Bar Manufacturers

Iron square bars have become a staple in various industries due to their strength, versatility, and suitability for a wide range of applications. These bars are commonly used in construction, manufacturing, and DIY projects. As the demand for iron square bars continues to grow, manufacturers play a crucial role in supplying quality products to meet the needs of different sectors. This article delves into the world of iron square bar manufacturers, exploring their significance, production processes, and selection criteria for buyers.

Why Choose Iron Square Bars?

Iron square bars are favored for their robustness and structural integrity. Their square shape makes them easy to handle and work with, providing stability when used in various applications. Additionally, they are available in different grades and sizes, which allows manufacturers and builders to select the right type based on specific project requirements. Common uses of iron square bars include creating frames, supports, and reinforcements in construction, as well as in the production of machinery and tools.

The Manufacturing Process

The production of iron square bars involves several key steps, which can vary depending on the manufacturer. Generally, the process includes

1. Raw Material Selection High-quality iron ore or scrap metal is sourced to ensure that the final product meets industry standards.

2. Melting The selected materials are heated in a furnace to a molten state. This process requires precise temperature control to achieve the desired chemical composition.

3. Casting Once the iron is molten, it is poured into molds to form the basic shape of square bars. The molds are designed to create a consistent size and weight.

iron square bar manufacturers

5. Cutting and Finishing The rolled bars are cut to the required lengths and subjected to finishing processes like machining, grinding, or surface treatment, which enhances their durability and aesthetic appeal.

6. Quality Control Before shipping, the bars undergo rigorous quality checks to ensure they meet the necessary specifications and standards.

Key Considerations When Choosing Manufacturers

1. Quality Standards Buyers should look for manufacturers that adhere to industry standards, such as ASTM or ISO certifications. This ensures the iron square bars meet safety and performance requirements.

2. Production Capacity Depending on the scale of projects, buyers may require a manufacturer with significant production capabilities to meet large orders without delays.

3. Customization Some manufacturers offer customization options for size, weight, and finish, allowing customers to tailor products to their specific needs.

4. Reputation and Reviews Researching the reputation of manufacturers through customer reviews and testimonials can provide insights into their reliability and product quality.

5. Pricing While cost is always a factor, it should not be the sole consideration. Understanding the price-performance ratio is essential; sometimes, a higher initial investment can lead to better long-term value.

Conclusion

Iron square bar manufacturers play a vital role in the construction and manufacturing industries by providing essential materials that contribute to the structural integrity of numerous projects. As the demand for these materials grows, manufacturers must continually adapt to market needs while maintaining high standards of quality and innovation. Buyers should take the time to research and choose reputable manufacturers to ensure they receive products that not only meet their specifications but also contribute to the overall success of their projects. With the right materials, builders and manufacturers can achieve their goals effectively and efficiently.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

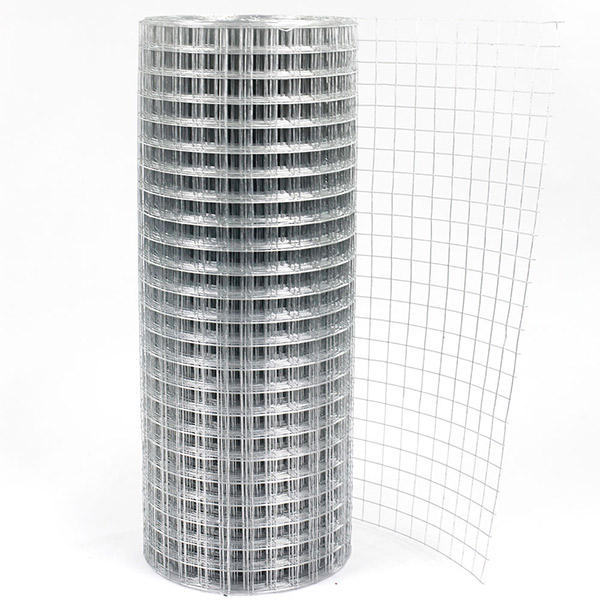

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025