Dec . 09, 2024 23:08 Back to list

Leading Manufacturer of High-Quality Hot-Dipped Galvanized Iron Wire Solutions

Hot Dipped Galvanized Iron Wire An Overview of Manufacturers and Their Offerings

Hot dipped galvanized iron wire is a versatile material that finds extensive application in various industries, including construction, agriculture, and manufacturing. It is renowned for its corrosion resistance and durability, making it a preferred choice for many builders and manufacturers. In this article, we will explore the characteristics of hot dipped galvanized iron wire, the manufacturing process, its applications, and what to consider when selecting a manufacturer.

What is Hot Dipped Galvanized Iron Wire?

Hot dipped galvanized iron wire is produced by immersing iron or steel wire into a molten zinc bath. This process creates a protective layer of zinc that adheres to the wire, providing resistance against rust and oxidation. The thickness of the zinc coating varies and is determined by the specific requirements of the application, making this wire suitable for both indoor and outdoor use. The galvanized layer ensures that the wire maintains its strength and integrity over time, even in harsh environmental conditions.

The Manufacturing Process

The manufacturing process of hot dipped galvanized iron wire involves several stages

1. Wire Drawing The first step involves drawing iron or steel rods through a series of dies to achieve the desired wire diameter. This step increases the wire's tensile strength and prepares it for galvanization.

2. Cleaning Before galvanization, the wire is thoroughly cleaned to remove any contaminants such as oil, dirt, or rust. This is typically done using an acid solution, which ensures that the zinc coating properly adheres to the wire.

3. Galvanization The cleaned wire is then immersed in a molten zinc bath at high temperatures. The duration of immersion affects the thickness of the zinc coating, which impacts the wire's overall durability.

4. Cooling After being removed from the zinc bath, the wire is cooled down rapidly. This cooling process solidifies the zinc coating, resulting in a durable and corrosion-resistant product.

5. Quality Control Reputable manufacturers conduct rigorous quality control checks throughout the production process. This includes tensile testing, coating thickness measurements, and visual inspections to ensure that the wire meets industry standards.

Applications of Hot Dipped Galvanized Iron Wire

Hot dipped galvanized iron wire is used in a variety of applications, such as

hot dipped galvanized iron wire manufacturer

- Fencing The wire is commonly used for constructing fences in agricultural and residential settings. Its rust-resistant properties ensure longevity, making it ideal for boundary fencing and animal enclosures.

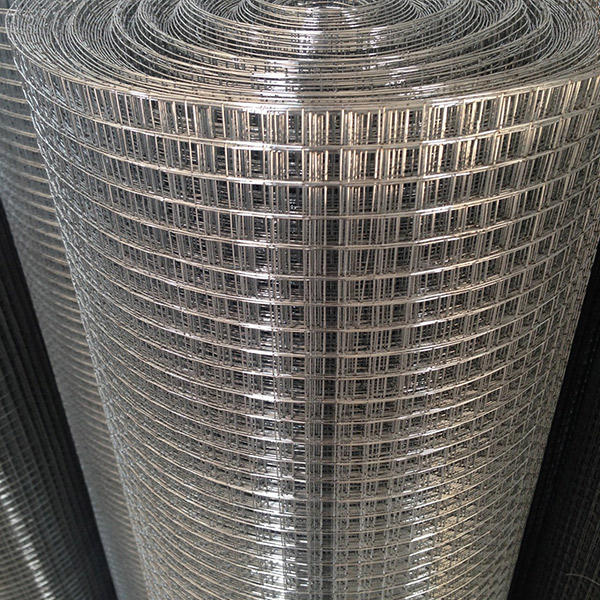

- Construction In the construction industry, galvanized wire is employed in reinforcing concrete structures

. It is also used in the production of wire mesh, which provides added strength and stability to buildings.- Commercial Uses Manufacturers utilize galvanized wire for various commercial applications, including the production of hangers, tying materials, and in the automotive industry for wire harnesses.

- Crafting and Artistic Projects Many artists and craftsmen use hot dipped galvanized wire in their creations due to its flexibility and aesthetic appeal.

Choosing the Right Manufacturer

When selecting a hot dipped galvanized iron wire manufacturer, several factors should be considered

1. Quality Standards Ensure the manufacturer adheres to international quality standards, such as ISO certifications. This guarantees that the products meet specific quality criteria.

2. Product Variety Look for manufacturers that offer a wide range of wire sizes and zinc coating thicknesses to cater to various applications.

3. Customization If you have specific requirements, consider manufacturers that provide customization options for wire diameter, coating thickness, and packaging.

4. Customer Support A reliable manufacturer should offer excellent customer service, including pre-sales consultations and after-sales support.

5. Reputation Research the manufacturer’s reputation in the industry through reviews and case studies. A well-established manufacturer with positive feedback is often a safe choice.

Conclusion

Hot dipped galvanized iron wire serves as an essential component across various industries, providing strength and durability while resisting corrosion. Understanding the manufacturing process, applications, and critical considerations when choosing a manufacturer can help stakeholders make informed decisions. By partnering with a reputable manufacturer, businesses can ensure they receive high-quality products that meet their specific needs and standards.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025