Nov . 09, 2024 11:23 Back to list

High-Quality Hot Dipped Galvanized Iron Wire Supplier for Various Applications

The Rise of Hot Dipped Galvanized Iron Wire Manufacturers

In the modern industrial landscape, hot dipped galvanized iron wire has emerged as a critical material in various applications, ranging from construction to agriculture. The process of hot-dipping involves coating iron wire with zinc, which significantly enhances its resistance to corrosion, durability, and overall lifespan. As demand for high-quality galvanized wire continues to grow, the role of manufacturers in this sector is becoming increasingly important.

Understanding Hot Dipped Galvanization

Hot dipped galvanization is a process where iron wire is submerged in molten zinc. This method creates a robust bond between the iron and zinc, providing an effective barrier against moisture and other corrosive elements. The resultant wire not only withstands harsh environmental conditions but also preserves its structural integrity over time. This makes it an ideal choice for applications in areas with high humidity, chemical exposure, or saline environments.

Applications of Hot Dipped Galvanized Iron Wire

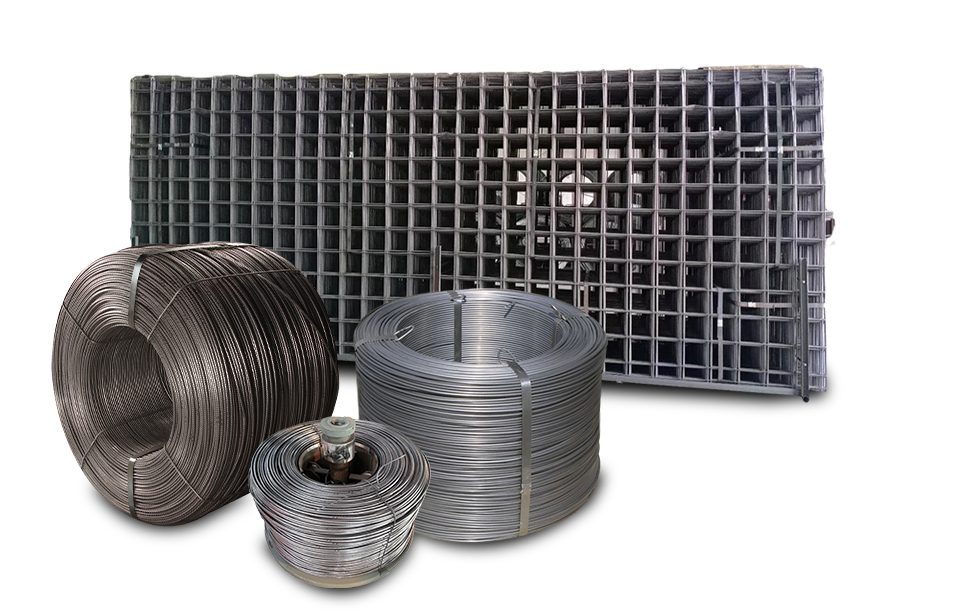

The applications of hot dipped galvanized iron wire are diverse. In construction, it is used for reinforcing concrete, crafting fences, and creating mesh for various structures. The agriculture sector utilizes this wire for fencing livestock, trellising plants, and supporting crop structures. Additionally, its durability makes it a common choice in the manufacturing of wire products, such as hangers, hooks, and decorative elements.

Furthermore, the automotive industry has found uses for galvanized wire in certain components, taking advantage of its strength and corrosion resistance. As industries evolve and eco-friendly practices gain importance, the demand for materials with extended lifespans such as hot dipped galvanized iron wire is likely to increase.

The Role of Manufacturers

The role of hot dipped galvanized iron wire manufacturers is crucial in meeting the burgeoning demand across various sectors. These manufacturers are tasked with ensuring the quality and consistency of their products. The manufacturing process involves several stages, including wire drawing, cleaning, galvanizing, and finally, quality assurance.

hot dipped galvanized iron wire manufacturer

Quality control is particularly important in this industry, as inconsistencies in the galvanization process can lead to product failure. Leading manufacturers employ advanced technology and stringent quality standards to ensure that their wire products meet or exceed industry benchmarks.

Innovations in Production

Innovation is at the heart of effective manufacturing. Many hot dipped galvanized iron wire manufacturers are investing in research and development to enhance production techniques and improve the properties of their products. For instance, some manufacturers are exploring new galvanizing methods that use less energy or produce less waste, aligning with sustainable manufacturing practices. Others are developing specialized coatings that enhance the wire’s properties even further, making it suitable for unique applications.

Moreover, the integration of automation and smart technologies in production processes allows manufacturers to increase efficiency and reduce costs. By implementing IoT (Internet of Things) solutions, companies can monitor production lines in real-time, ensuring minimal downtime and consistent output quality.

Market Trends and Future Outlook

As urbanization and industrialization continue to advance, the global market for hot dipped galvanized iron wire is expected to grow significantly. Regions with booming construction sectors and agricultural development, particularly in Asia and Africa, will likely see a surge in demand.

Additionally, as environmental concerns rise, there will be a push for sustainable practices in production and material use. This shift will create opportunities for manufacturers who prioritize eco-friendly approaches in their operations.

In conclusion, hot dipped galvanized iron wire manufacturers are essential players in the materials sector, contributing to various industries with their products. Their commitment to quality, innovation, and sustainability will drive growth as the demand for durable, corrosion-resistant materials continues to rise, paving the way for further advancements in this vital market.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025