Oct . 13, 2024 09:23 Back to list

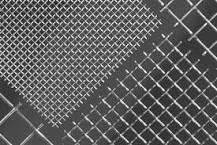

hot dipped galvanized drain grates 30x3mm factories

Hot dipped galvanized drain grates are an essential component in various construction and drainage systems, providing both functionality and durability. These grates are available in various sizes, with the 30x3mm specification being particularly popular due to its robust nature and effective drainage capabilities.

The process of hot dipping galvanization involves coating the metal drain grates with zinc through a dipping process. This method ensures that the grates are highly resistant to corrosion, rust, and other environmental factors that might degrade the metal over time. As a result, hot dipped galvanized drain grates offer a long service life and require minimal maintenance, making them an attractive option for both residential and commercial applications.

Factories that produce these drain grates use advanced manufacturing techniques to ensure high quality and precision. The production process begins with the selection of high-grade steel or cast iron, which forms the basis of the grates. The material is then cut, shaped, and molded to the desired specifications, such as the 30x3mm dimensions. After shaping, the grates undergo the galvanization process. The zinc coating not only provides protection but also enhances the aesthetic appeal of the grates, making them suitable for visible areas in parks, streets, and plazas.

hot dipped galvanized drain grates 30x3mm factories

These drain grates are designed to handle significant loads, making them ideal for use in heavy traffic areas such as roadways and parking lots. Their structured design ensures efficient water drainage, preventing pooling and promoting safety. Furthermore, their slip-resistant surfaces reduce the risk of accidents, making them an essential feature in public infrastructure.

In addition to their practicality, hot dipped galvanized drain grates are environmentally friendly as they can be recycled at the end of their lifespan, reducing waste and promoting sustainability. Many factories are also adopting eco-friendly practices in their production processes, further minimizing environmental impact.

In conclusion, hot dipped galvanized drain grates, especially those manufactured in the 30x3mm specification, are vital components in modern drainage systems. Their combination of durability, corrosion resistance, and effectiveness in water management makes them ideal for various applications. As the demand for high-quality construction materials continues to grow, factories specializing in these products play a crucial role in providing reliable and sustainable solutions for builders and municipalities alike.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025