Oct . 18, 2024 09:25 Back to list

Top Manufacturers of Hot Dip Galvanized Steel Grating for Durable Industrial Applications

Hot Dip Galvanized Steel Grating Manufacturers An Overview

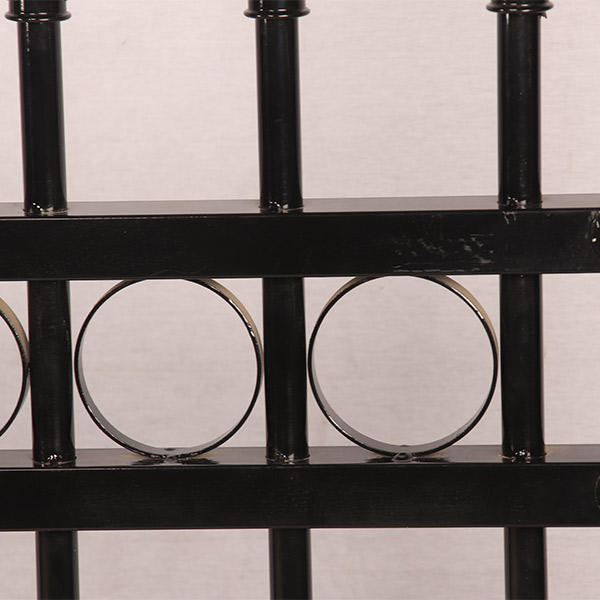

Hot dip galvanized steel gratings have emerged as a preferred choice in various industrial applications due to their remarkable durability, corrosion resistance, and strength. This article delves into the significance of hot dip galvanized steel gratings, their manufacturing process, and highlights some of the well-known manufacturers in the industry.

Understanding Hot Dip Galvanizing

Hot dip galvanizing is a process that involves coating steel or iron with a layer of zinc to prevent corrosion. This method is highly effective because zinc has a unique ability to protect steel through both barrier and galvanic protection. When steel grating is subjected to this process, it gains enhanced longevity, making it ideal for outdoor and harsh environments. Applications of hot dip galvanized steel grating are widespread, spanning construction, manufacturing, marine, and even transportation sectors.

Advantages of Hot Dip Galvanized Steel Grating

1. Corrosion Resistance The primary benefit of hot dip galvanization is its exceptional resistance to rust and corrosion. This quality makes it suitable for environments exposed to moisture, chemicals, and extreme weather conditions.

2. Cost-Effectiveness While the initial cost of hot dip galvanized gratings may be higher than that of ordinary steel, their long lifespan dramatically reduces the need for maintenance and replacement, leading to significant savings in the long run.

3. High Strength-to-Weight Ratio Steel grating materials offer tremendous strength while remaining lightweight. This characteristic facilitates easier installation and transportation.

4. Safety The slip-resistant surface of galvanized steel grating enhances safety in work environments, reducing the risk of slips and falls.

5. Versatility Hot dip galvanized steel grating can be customized in various sizes, shapes, and designs, making it suitable for a range of applications, from flooring to stair treads and platform supports.

The Manufacturing Process

The production of hot dip galvanized steel grating involves several critical steps

1. Material Selection The process starts with selecting high-quality steel sheets or bars that will be cut and shaped into grating.

2. Cutting and Welding The steel materials are cut into required sizes and welded to create the grating structure. This process ensures strength and stability in the final product.

hot dip galvanized steel grating manufacturers

3. Cleaning Before the galvanization process, the welded grating must be thoroughly cleaned. This usually involves a combination of alkaline cleaning, pickling in hydrochloric acid, and rinsing to remove any rust, grease, and mill scale.

4. Galvanization The cleaned grating is dipped in a molten zinc bath, which coats the steel with a thick layer of zinc. This step is crucial as it defines the corrosion-resistant properties of the grating.

5. Cooling After galvanization, the grating is cooled, allowing the zinc to solidify and bond with the steel. The result is a hard, durable coating that is effectively fused to the metal.

6. Quality Inspection The final step involves rigorous quality checks to ensure that the gratings meet industry standards and specifications. This includes testing for dimensions, coating thickness, and surface quality.

Leading Manufacturers in the Industry

With the growing demand for hot dip galvanized steel gratings, several manufacturers stand out for their quality and innovation

1. Drainage and Grating Solutions This company specializes in producing a wide range of steel gratings specifically designed for drainage systems. Their hot dip galvanized products are known for their durability.

2. Global Steel Grating A leader in the industry, Global Steel Grating offers customized solutions for various applications. They are known for their advanced manufacturing techniques and high-quality standards.

3. Pacific Steel Grating Renowned for their vast catalog of steel grating products, Pacific Steel Grating places a strong emphasis on sustainability and environmentally friendly manufacturing practices.

4. Eagle Grating With years of experience in the industry, Eagle Grating provides exceptional products tailored to meet specific client needs. Their commitment to innovation and quality makes them a preferred choice among engineers and contractors.

5. Hilti Corporation Known for their construction tools and technology, Hilti also produces high-quality hot dip galvanized steel gratings that cater to various demanding applications in the construction sector.

Conclusion

Hot dip galvanized steel grating manufacturers play an essential role in providing solutions for industries requiring sturdy, long-lasting, and cost-effective products. As the demand for robust materials continues to grow, these manufacturers are committed to innovating and ensuring quality, making galvanized steel gratings a reliable choice for diverse applications. Whether it’s in an industrial plant or a construction site, the importance of quality steel grating cannot be overstated, as it forms the backbone of safety and efficiency in many operations.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025