Nov . 10, 2024 19:35 Back to list

Hog Wire Fence Panels Manufacturing and Supply Solutions for Your Needs

Exploring Hog Wire Fence Panels A Comprehensive Guide to Factories and Manufacturing

Hog wire fence panels have become increasingly popular in agricultural settings and residential properties alike, due to their durability, aesthetic appeal, and versatility. These fencing panels are typically made from high-quality steel, galvanized to resist corrosion, and designed to contain or exclude livestock while offering visibility and ventilation. This article delves into the production of hog wire fence panels, focusing on the manufacturing processes and factory operations involved in their creation.

The Manufacturing Process

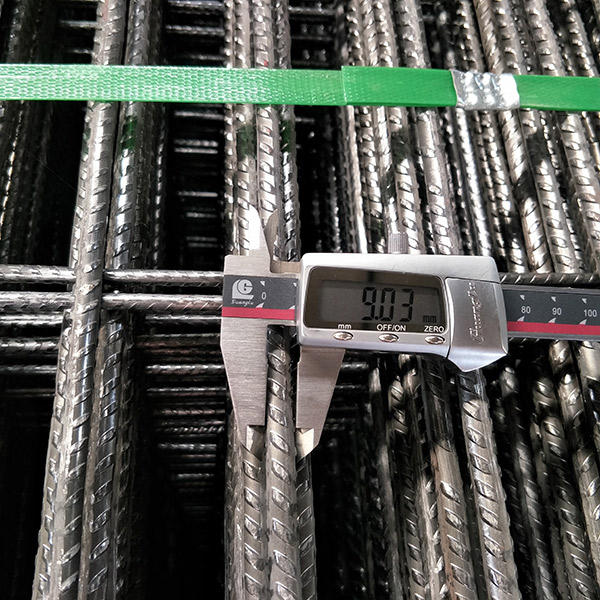

The production of hog wire fence panels starts with sourcing raw materials. Factories begin by selecting high-quality steel or wire, which is then cut and prepared according to the desired specifications. This raw material forms the basis of the panels and is essential in ensuring the final product meets rigorous standards for strength and resilience.

Once the wire is acquired, it undergoes a series of processes. One of the most critical steps is welding. In many factories, machines are employed to weld the wire intersections securely, creating a robust frame that can withstand pressure from both livestock and environmental factors. High-tech welding techniques ensure consistent quality across all panels, and these methods significantly enhance the overall strength of the fence.

After welding, the panels move on to the galvanization process. Galvanization involves coating the steel with a layer of zinc to protect it from rust and corrosion. This step is crucial for hog wire fences, especially in areas with high moisture content or harsh weather conditions. The galvanization process can be either hot-dipped or electrowelded, depending on the factory’s capabilities and the desired finish of the product.

Quality Control and Customization

hog wire fence panels factory

Once the panels are produced, they undergo stringent quality control inspections. Factories implement various testing methods to ensure that the panels can withstand significant weights and pressures. This includes testing for weld strength, corrosion resistance, and overall integrity. Quality control is a vital part of the manufacturing process, as it helps maintain the factory's reputation and ensures customer satisfaction.

Customization is another essential aspect of hog wire fence panel manufacturing. Many factories offer a range of sizes and designs to suit the specific needs of their clients. Whether it’s adjusting the height of the panels or altering the spacing between wires, customization allows for a tailored solution that fits various applications, from farmyards to residential gardens.

Market Demand and Sustainability

The market for hog wire fence panels has been on the rise, driven by an increasing interest in sustainable living and responsible farming practices. Many consumers are looking for cost-effective, durable fencing solutions that do not sacrifice aesthetics. As a result, factories are refining their processes to meet growing demand while adopting more environmentally friendly practices, such as using recycled materials wherever possible.

Moreover, many manufacturers are investing in technology to enhance production efficiency and reduce waste. Automation in the form of robotic welding and material handling streams is revolutionizing the industry, allowing factories to increase output without compromising on quality.

Conclusion

Hog wire fence panels serve as an essential component in both agricultural and residential settings, providing a combination of strength, visibility, and aesthetics. The factories that produce these panels play a crucial role in ensuring that they meet the needs of consumers while adhering to high-quality standards. As demand continues to grow, the manufacturing processes and technologies will likely evolve, leading to even more innovative and sustainable solutions in the fencing industry. Choosing the right hog wire fence panels can make a significant difference in livestock management and property protection—ensuring the investment pays off for years to come.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025