Dec . 04, 2024 04:55 Back to list

Top Manufacturers of High-Quality Galvanized Iron Wire for Reliable Performance

Understanding High-Quality Galvanized Iron Wire Manufacturers

When it comes to construction, manufacturing, and various DIY projects, high-quality galvanized iron wire is an essential material that is frequently sought after. This type of wire is renowned for its durability, corrosion resistance, and versatility, making it a preferred choice for a variety of applications. Consequently, the role of manufacturers in producing high-quality galvanized iron wire cannot be understated. In this article, we will delve into what constitutes high-quality galvanized iron wire manufacturers, the manufacturing process, and the significance of choosing the right supplier for your needs.

What is Galvanized Iron Wire?

Galvanized iron wire is made of iron that has been coated with a layer of zinc to protect it from rust and corrosion. This process, known as galvanization, involves dipping the iron wire into molten zinc or applying a zinc coating through electroplating. The primary purpose of galvanization is to extend the lifespan of the wire and enhance its mechanical properties. High-quality galvanized iron wire is typically characterized by a uniform coating, minimal spalling, and excellent tensile strength.

Key Attributes of Quality Manufacturers

When searching for high-quality galvanized iron wire manufacturers, several essential attributes should be considered

1. Reputation and Experience Manufacturers with a longstanding reputation in the industry are often more reliable. Years of experience typically result in better production practices and a deep understanding of customer needs.

2. Quality Control Standards Quality must be consistent. Manufacturers should have stringent quality control measures in place, which include testing for strength, coating thickness, and resistance to corrosion. Look for certification such as ISO or similar quality assurance standards.

3. Raw Material Sourcing The quality of the raw materials used in manufacturing galvanized iron wire plays a significant role in the final product’s quality. Reputable manufacturers will source high-grade iron and zinc to ensure superior results.

4. Advanced Manufacturing Techniques Technological advancements can improve production efficiency and quality. Manufacturers who utilize modern equipment and innovative techniques are often able to produce better quality wire at competitive prices.

5. Customer Service and Support Excellent customer service is crucial, as manufacturers should be responsive to inquiries and willing to assist with any issues that may arise after the sale.

Manufacturing Process

high quality galvanized iron wire manufacturers

The process of manufacturing galvanized iron wire typically involves the following stages

1. Wire Drawing This is the initial step where raw iron rods are drawn through a series of dies to create wires of specific gauges and strengths.

2. Cleaning The drawn wire must be cleaned to remove any impurities. This step often involves pickling, which uses an acid solution to remove iron oxide and other contaminants.

3. Galvanization The cleaned wire is then subjected to the galvanization process. In hot-dip galvanization, the wire is submerged in molten zinc, creating a robust and uniform coating. In electro-galvanization, an electric current is used to deposit zinc onto the wire's surface.

4. Finishing After galvanization, the wire goes through a finishing process where it may be coiled, packaged, or treated for additional properties based on customer requirements.

5. Quality Assurance Finally, the wire undergoes rigorous quality checks to ensure adherence to set standards before being dispatched to customers.

Importance of Choosing the Right Manufacturer

Selecting the right manufacturer for galvanized iron wire is crucial for several reasons. Firstly, inferior quality wire can lead to structural failures, safety hazards, and increased costs due to replacements or repairs. Secondly, reputable manufacturers often provide warranties and guarantees, giving customers peace of mind regarding their purchase.

Additionally, a reliable supplier can offer custom solutions to meet specific project requirements, ensuring that clients receive the most suitable product for their needs. Be it for fencing, construction, or artisanal projects, having access to high-quality galvanized iron wire can significantly impact the outcome of any project.

Conclusion

In conclusion, high-quality galvanized iron wire plays a pivotal role across various industries, and the importance of choosing the right manufacturer cannot be overstated. By understanding what makes a manufacturer reputable and knowledgeable about the manufacturing process, customers can make informed decisions that lead to better project outcomes and long-term satisfaction. Whether you are a contractor, a homeowner, or an industrial buyer, investing in high-quality galvanized iron wire from a reliable manufacturer is a decision that will pay off in the long run.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

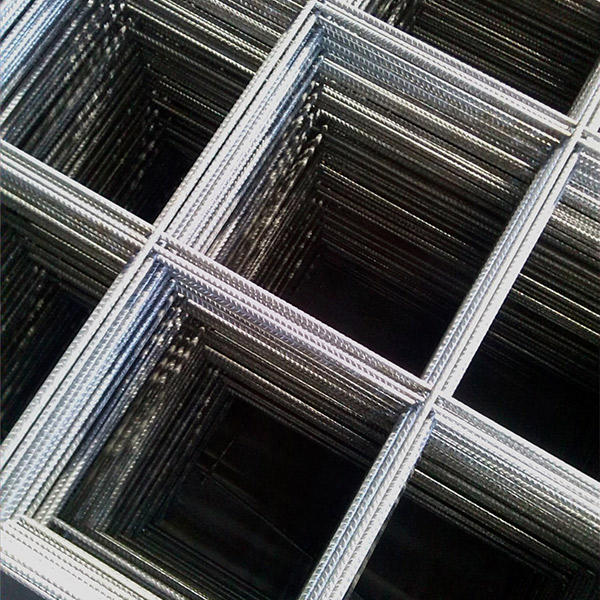

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025