Nov . 12, 2024 10:31 Back to list

high quality galvanized iron wire

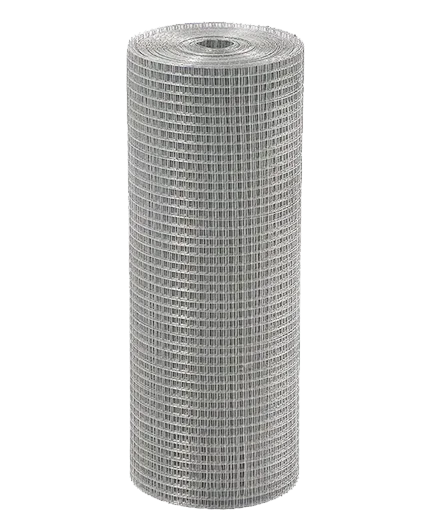

High-Quality Galvanized Iron Wire A Versatile Material for Various Applications

Galvanized iron wire has emerged as a vital material in numerous industries due to its remarkable durability, strength, and resistance to corrosion. This article explores the characteristics, manufacturing process, applications, and benefits of high-quality galvanized iron wire.

Understanding Galvanization

Galvanization is a process in which iron or steel is coated with a thin layer of zinc to protect it from corrosion. The zinc acts as a sacrificial anode, meaning it will corrode before the underlying metal does, thereby prolonging the life of the wire. The quality of galvanized iron wire is predominantly determined by the thickness of the zinc coating and the quality of the base iron or steel used.

Production Process

The production of high-quality galvanized iron wire involves several key steps

1. Raw Material Selection The process begins with choosing high-grade steel or iron rods. The quality of the base metal significantly impacts the durability and performance of the final product.

2. Wire Drawing This step involves pulling the raw metal through a series of dies to achieve the desired diameter. Different thicknesses are available depending on the specific requirements of the end-use applications.

3. Cleaning and Preparation The drawn wire is cleaned to remove any impurities, oil, or scale. This preparation is essential for ensuring that the zinc adheres properly during the galvanizing process.

4. Galvanization The clean wire is then submerged in a molten zinc bath. The temperature and duration of immersion are carefully controlled to achieve an even and adequate coating that meets industry standards.

5. Cooling and Inspection After galvanization, the wire is cooled. It is then inspected to ensure consistency, quality, and adherence to specifications. High-quality galvanized wire demonstrates uniformity in appearance and thickness.

Applications of Galvanized Iron Wire

High-quality galvanized iron wire is exceptionally versatile and is used in a wide range of applications, including

1. Construction It is commonly used in construction for reinforcing concrete, making wire mesh, and providing support structures. Its corrosion resistance makes it ideal for use in harsh environments.

high quality galvanized iron wire

2. Fencing Galvanized wire is a popular choice for fencing due to its strength and durability. It can be used for agricultural, residential, and industrial fencing solutions, ensuring long-lasting barriers against intruders or livestock.

3. Wire Products It is utilized to manufacture a variety of wire products such as hangers, nails, and fasteners. The corrosion resistance helps these products maintain their integrity over time.

4. Crafts and Homemade Items Galvanized wire is favored in DIY projects and crafts, offering strength and ease of manipulation for various artistic and functional creations.

5. Electrical Applications In some cases, galvanized wire is used in electrical applications where grounding or support is necessary, benefiting from its conductive and anti-corrosive properties.

Benefits of High-Quality Galvanized Iron Wire

Investing in high-quality galvanized iron wire brings several advantages

1. Longevity The protective zinc coating significantly increases the lifespan of the wire, making it a cost-effective choice in the long run.

2. Strength Galvanized iron wire exhibits excellent tensile strength, making it suitable for applications that require durable and reliable materials.

3. Corrosion Resistance Its ability to resist rust and corrosion makes it ideal for outdoor and high-moisture applications, reducing maintenance costs.

4. Versatility The wide availability of gauge sizes and the adaptability of galvanized wire make it suitable for various uses across different industries.

5. Aesthetic Appeal Galvanized iron wire has an attractive finish, making it suitable for visible applications where appearance is also a consideration.

Conclusion

High-quality galvanized iron wire is an essential material that stands out for its durability, strength, and resistance to environmental factors. Its versatile applications across various industries, combined with its cost-effectiveness, make it a preferred choice among manufacturers and consumers alike. Whether it is used in construction, fencing, or crafts, investing in high-quality galvanized iron wire ensures reliability and longevity, securing its place as a valuable resource in today's market.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025