Jul . 26, 2024 13:12 Back to list

High-Quality OEM Welded Iron Wire Mesh in 50x50 mm Size for Various Applications

Understanding OEM Welded Iron Wire Mesh 50x50

Welded iron wire mesh is an essential product in various industries, widely recognized for its strength, versatility, and durability. One of the most sought-after specifications in this category is the OEM welded iron wire mesh with a 50x50 millimeter opening. This specification caters to many applications, from construction and agriculture to security and fencing needs.

What is Welded Iron Wire Mesh?

Welded iron wire mesh consists of wires that are welded together at intersections to form a grid-like structure. The 50x50 in its name refers to the mesh opening size, indicating that each square in the mesh measures 50 millimeters both horizontally and vertically. The mesh is typically produced using high-quality iron wire, which can be galvanized or coated to enhance its resistance to corrosion and rust.

Benefits of OEM Welded Iron Wire Mesh

1. Customization and Quality Assurance The term OEM (Original Equipment Manufacturer) signifies that the welded mesh can be customized according to specific requirements and standards set by the client. This means that dimensions, coatings, and finishes can be tailored to meet the needs of various projects, ensuring optimal performance and satisfaction.

2. Versatile Applications The 50x50 mesh size makes it suitable for a range of uses. In construction, it is often employed for reinforcement in concrete structures, offering additional strength and durability. In agriculture, it is used for fencing and livestock enclosures, ensuring the safety and security of animals. Moreover, it finds applications in the production of cages, storage bins, and various industrial products.

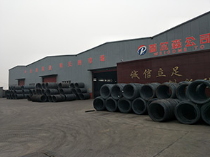

oem welded iron wire mesh 50x50

3. Durability and Strength One of the standout features of welded iron wire mesh is its sturdy construction. The welding process creates a robust bond between the wires, enhancing the overall tensile strength of the mesh. This durability makes it ideal for heavy-duty applications where environmental exposure is inevitable.

4. Ease of Installation Welded iron wire mesh is relatively easy to install. It can be cut to size or shaped to fit specific applications, making it a convenient choice for contractors and DIY enthusiasts alike. Whether used as a fence or as a concrete reinforcement, the installation process is straightforward, reducing labor costs and time.

5. Cost-Effectiveness Considering its durability and longevity, OEM welded iron wire mesh presents a cost-effective solution for many projects. The long lifespan of the product reduces the need for frequent replacements, ultimately saving money in the long run.

6. Aesthetic Appeal Although primarily functional, welded iron wire mesh can also be designed for aesthetic purposes. With various finishes and coatings available, such as powder coating or galvanization, it can complement the design of residential properties or commercial buildings.

Conclusion

OEM welded iron wire mesh with a 50x50 specification stands out as a reliable solution for a multitude of applications. Its robust construction, coupled with the ability to customize to specific needs, makes it a popular choice across various industries. From reinforcing concrete structures to providing security in agricultural settings, the versatility and durability of this mesh type cannot be overstated. As technology advances and manufacturing practices improve, we can expect even greater innovations and applications for welded iron wire mesh, solidifying its place as a staple in modern infrastructure and construction.

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025