Jul . 26, 2024 13:17 Back to list

High-Quality Fiberglass Mesh Net Manufacturing Solutions for Diverse Applications and Industries

The Significance of Fiberglass Net Mesh Factories in Modern Industries

Fiberglass net mesh has transformed various industries, from construction to agriculture, due to its unique properties and versatility. As demand grows, the role of fiberglass net mesh factories becomes increasingly crucial. These facilities are at the forefront of producing high-quality materials that enhance performance and durability across multiple applications.

Understanding Fiberglass Net Mesh

Fiberglass net mesh is made from thin strands of glass fibers woven together to form a durable and flexible fabric. This mesh is known for its high tensile strength, resistance to chemical corrosion, and ability to withstand extreme temperatures. It is lightweight yet incredibly strong, making it an ideal reinforcement material in various sectors.

Applications in Construction

In construction, fiberglass net mesh is primarily used for reinforcing concrete and plaster. When embedded into walls, ceilings, and floors, it helps distribute stress evenly, preventing cracks and ensuring structural integrity. Its use in the insulation of buildings has also gained traction, as it enhances thermal performance while being resistant to environmental factors that can deteriorate other materials. Furthermore, fiberglass net mesh is employed in the production of façade systems and external wall insulation, offering a balance between durability and aesthetic appeal.

Role in Agriculture

Agriculture also benefits significantly from fiberglass net mesh, especially in greenhouses and crop protection. The lightweight yet robust nature of the mesh allows for easy installation and ensures that plants are protected from pests without hindering sunlight or water penetration. Additionally, it offers support for climbing plants, helping them thrive in vertical growth conditions. As sustainability becomes a focal point in farming, the durability and reusability of fiberglass net mesh make it an environmentally friendly choice.

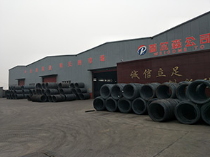

fiber glass net mesh factory

Advantages in Industry

The production process in fiberglass net mesh factories is essential in maintaining high standards of quality. Factories focus on technological advancements and quality control to ensure that the mesh produced can withstand various stresses and environmental conditions. Enhanced production techniques, such as automated weaving and advanced coating methods, have allowed factories to improve the strength, flexibility, and corrosion resistance of their products.

Moreover, fiberglass net mesh is increasingly being incorporated into composites, where it serves as a reinforcing agent for materials like plastics and resins. This application is particularly prominent in the automotive and aerospace industries, where lightweight materials are essential for fuel efficiency and performance.

Economic Impact

The fiberglass net mesh industry is also a significant contributor to the economy. As demand for fiberglass products increases, so do job opportunities within manufacturing plants and related sectors. The growth of construction and agricultural sectors globally propels the need for high-quality fiberglass mesh, leading to further investments in factories that produce these materials.

Conclusion

Fiberglass net mesh factories play a vital role in meeting the modern demands of various industries. By producing durable and versatile materials, these factories support innovation and sustainability in construction, agriculture, and other sectors. As industries continue to evolve, the importance of fiberglass net mesh and the factories that produce them will undoubtedly increase, making them integral to future advancements in materials science and engineering. Thus, investing in the development and expansion of fiberglass net mesh factories is not just beneficial; it is essential for a more resilient and sustainable future.

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025

-

High Quality Black Annealed Wire - Durable Iron Wire 2mm from Leading Manufacturer & Supplier Factory

NewsJul.08,2025

-

Produce Hot Dipped Galvanized Steel Grating - High Quality Grating Supplier & Manufacturer

NewsJul.08,2025

-

Galvanized Iron Welded Wire Mesh Panels – Durable, Rust-Resistant, Best Price Manufacturer

NewsJul.07,2025

-

High Quality Concrete Reinforcing Welded Wire Mesh - Durable 8mm Steel Bar, Q188, A393, F72, High Strength Mesh Solutions

NewsJul.07,2025

-

High-Quality Redrawn G.I. Wire Leading Manufacturers & Suppliers

NewsJul.07,2025