Aug . 11, 2024 13:18 Back to list

High-Quality Cold Drawn Spring Wire Production for Superior Performance and Durability

Cold Drawn Spring Wire Manufacturers An Essential Component in Industrial Applications

In today's rapidly advancing industrial landscape, the demand for high-quality components is ever-increasing. Among these components, cold drawn spring wire plays a pivotal role in manufacturing springs that are used in a variety of applications, from automotive systems to consumer electronics. As such, cold drawn spring wire manufacturers are crucial players in the supply chain, providing the essential materials that engineers and designers rely on to create reliable and durable products.

Understanding Cold Drawn Spring Wire

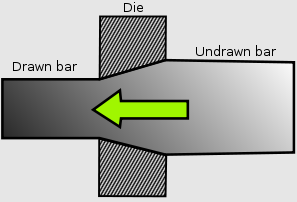

Cold drawn spring wire is produced through a process that involves pulling the wire through a die at room temperature, resulting in a reduction of diameter and an improvement in mechanical properties. This process not only enhances the wire’s strength but also improves its surface finish, making it highly suitable for spring applications. Various materials are used in the production of cold drawn spring wire, including high carbon steel, stainless steel, and alloy steels, each chosen based on the specific requirements of the end application.

Key Benefits of Cold Drawn Spring Wire

1. Enhanced Mechanical Properties The cold drawing process increases the tensile strength and yield strength of the wire, which is critical for the performance of springs. These enhanced mechanical properties allow springs to withstand greater stresses and strains, which is vital in many applications.

2. Precise Tolerances Cold drawn spring wire can be manufactured to very tight tolerances, which is essential for applications where precision is paramount. This level of precision ensures that the springs fit well into their designated spaces, perform reliably, and contribute to the overall efficiency of the system.

3. Improved Surface Finish The cold drawing process results in a smoother surface finish, thereby reducing wear and tear during use. This characteristic is especially important in applications where friction and fatigue can lead to premature failure.

cold drawn spring wire manufacturer

4. Versatility Cold drawn spring wire can be used in a wide range of spring types, including compression springs, extension springs, and torsion springs. This versatility makes it a favored choice among manufacturers across various sectors, including automotive, aerospace, and electronics.

The Role of Manufacturers in the Industry

Cold drawn spring wire manufacturers are essential in ensuring the availability and quality of this crucial material. They invest in advanced machinery and technology to optimize the drawing process and maintain strict quality control standards. ISO certifications and adherence to industry standards are often indicators of a manufacturer's commitment to quality.

These manufacturers also work closely with their clients to understand the specific requirements of each application. This collaboration can lead to the development of customized wire solutions that meet exact specifications, which can be a distinctive advantage in competitive markets.

Challenges Faced by Manufacturers

Despite their importance, cold drawn spring wire manufacturers face several challenges. Fluctuating raw material prices, environmental regulations, and the need for continuous innovation are just a few of the issues that require agile responses. Additionally, the increasing demand for high-performance materials means that manufacturers must continually invest in research and development to keep pace with market needs.

Conclusion

Cold drawn spring wire manufacturers play a critical role in diverse industrial applications, providing essential materials that contribute to the durability and reliability of products. As industry demands evolve, these manufacturers will need to adapt to new challenges and continue to innovate, ensuring they remain at the forefront of material science and engineering. In doing so, they will not only support their clients' manufacturing needs but also contribute to the overall advancement of technology across various sectors. As we move forward, the significance of quality suppliers in this niche market will undoubtedly become even more pronounced.

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|High Borosilicate Glass&Eco-Friendly Design

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Thermal Resistance Eco-Friendly Airtight Seal

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.17,2025

-

Diamond Steel Grating Factory: Leading Manufacturer & Supplier

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Premium Eco-Friendly Storage Solution|Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.16,2025