Jun . 25, 2024 22:28 Back to list

High-Quality Black Annealed Iron Wire Supplier Reliable Product Range

Black Iron Wire A Reliable Choice for Your Applications

In the vast landscape of industrial materials, black iron wire stands as a versatile and dependable option, particularly when it comes to black annealed wire suppliers. This article delves into the intricacies of this product, its properties, and why it is a sought-after choice among manufacturers and contractors worldwide.

Black iron wire, also known as carbon steel wire, is composed primarily of iron with a small percentage of carbon, which imparts strength and durability. The term black refers to the lack of surface treatment or galvanization, giving it a distinctive matte finish. Its raw material, iron ore, is abundant and cost-effective, making it an affordable option for various industries.

Annealing, the process through which the wire is heated and then cooled slowly, is crucial in black annealed wire. This treatment softens the material, reducing brittleness and enhancing malleability. As a result, the wire becomes more flexible, easier to shape, and less prone to breakage under stress. This makes it ideal for applications that require bending or forming, such as fencing, window screens, and electrical conduit.

When it comes to suppliers, there are numerous options available in the market, each with their own reputation and quality standards. A reliable black iron wire supplier should be able to offer consistent material specifications, adherence to industry standards, and prompt delivery. They should have a thorough understanding of the product's characteristics and be capable of providing technical support when needed They should have a thorough understanding of the product's characteristics and be capable of providing technical support when needed They should have a thorough understanding of the product's characteristics and be capable of providing technical support when needed They should have a thorough understanding of the product's characteristics and be capable of providing technical support when needed

They should have a thorough understanding of the product's characteristics and be capable of providing technical support when needed They should have a thorough understanding of the product's characteristics and be capable of providing technical support when needed black iron wire black annealed wire supplier.

One key factor to consider is the wire's gauge or diameter, which determines its tensile strength and suitability for specific tasks. Thicker wires are stronger but may be more rigid, while thinner ones are lighter and more flexible. It's essential to choose the right gauge based on the intended application to ensure optimal performance and longevity.

Another important aspect is the surface condition. While black iron wire lacks galvanization, it can be coated with different finishes to prevent corrosion, prolonging its service life. Suppliers who offer post-production treatments can cater to this need, ensuring a longer-lasting product for their customers.

In conclusion, black iron wire, particularly in its annealed form, is a practical and cost-effective choice for a wide range of applications. Its flexibility, strength, and ease of availability make it a popular material among suppliers. When selecting a supplier, focus on reliability, quality control, and customization options to ensure you receive the best product for your needs. In today's competitive market, partnering with a reputable black iron wire supplier is key to unlocking the full potential of this versatile material.

black iron wire black annealed wire supplier.

One key factor to consider is the wire's gauge or diameter, which determines its tensile strength and suitability for specific tasks. Thicker wires are stronger but may be more rigid, while thinner ones are lighter and more flexible. It's essential to choose the right gauge based on the intended application to ensure optimal performance and longevity.

Another important aspect is the surface condition. While black iron wire lacks galvanization, it can be coated with different finishes to prevent corrosion, prolonging its service life. Suppliers who offer post-production treatments can cater to this need, ensuring a longer-lasting product for their customers.

In conclusion, black iron wire, particularly in its annealed form, is a practical and cost-effective choice for a wide range of applications. Its flexibility, strength, and ease of availability make it a popular material among suppliers. When selecting a supplier, focus on reliability, quality control, and customization options to ensure you receive the best product for your needs. In today's competitive market, partnering with a reputable black iron wire supplier is key to unlocking the full potential of this versatile material.

They should have a thorough understanding of the product's characteristics and be capable of providing technical support when needed They should have a thorough understanding of the product's characteristics and be capable of providing technical support when needed

They should have a thorough understanding of the product's characteristics and be capable of providing technical support when needed They should have a thorough understanding of the product's characteristics and be capable of providing technical support when needed black iron wire black annealed wire supplier.

One key factor to consider is the wire's gauge or diameter, which determines its tensile strength and suitability for specific tasks. Thicker wires are stronger but may be more rigid, while thinner ones are lighter and more flexible. It's essential to choose the right gauge based on the intended application to ensure optimal performance and longevity.

Another important aspect is the surface condition. While black iron wire lacks galvanization, it can be coated with different finishes to prevent corrosion, prolonging its service life. Suppliers who offer post-production treatments can cater to this need, ensuring a longer-lasting product for their customers.

In conclusion, black iron wire, particularly in its annealed form, is a practical and cost-effective choice for a wide range of applications. Its flexibility, strength, and ease of availability make it a popular material among suppliers. When selecting a supplier, focus on reliability, quality control, and customization options to ensure you receive the best product for your needs. In today's competitive market, partnering with a reputable black iron wire supplier is key to unlocking the full potential of this versatile material.

black iron wire black annealed wire supplier.

One key factor to consider is the wire's gauge or diameter, which determines its tensile strength and suitability for specific tasks. Thicker wires are stronger but may be more rigid, while thinner ones are lighter and more flexible. It's essential to choose the right gauge based on the intended application to ensure optimal performance and longevity.

Another important aspect is the surface condition. While black iron wire lacks galvanization, it can be coated with different finishes to prevent corrosion, prolonging its service life. Suppliers who offer post-production treatments can cater to this need, ensuring a longer-lasting product for their customers.

In conclusion, black iron wire, particularly in its annealed form, is a practical and cost-effective choice for a wide range of applications. Its flexibility, strength, and ease of availability make it a popular material among suppliers. When selecting a supplier, focus on reliability, quality control, and customization options to ensure you receive the best product for your needs. In today's competitive market, partnering with a reputable black iron wire supplier is key to unlocking the full potential of this versatile material. Latest news

-

Chain Link Fence - Anping County Puersen | Durable, Versatile Fencing

NewsAug.15,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable Security&Wire Mesh

NewsAug.15,2025

-

Chain Link Fence: Durable & Versatile Security Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.15,2025

-

Chain Link Fence-Durable&Versatile|Anping County Puersen

NewsAug.15,2025

-

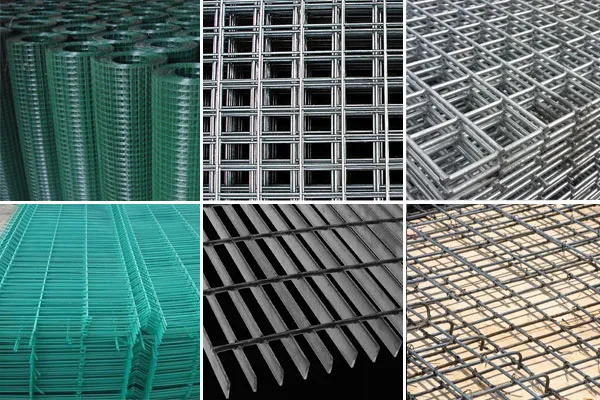

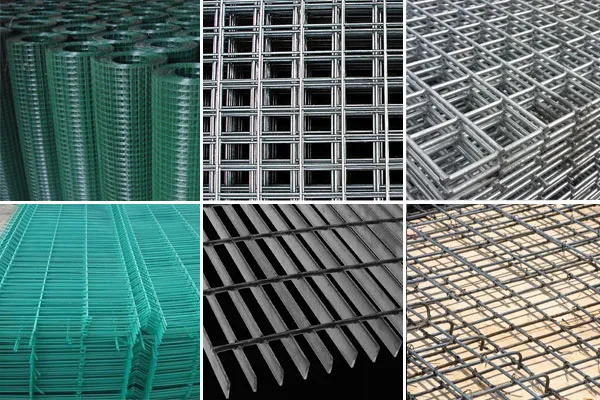

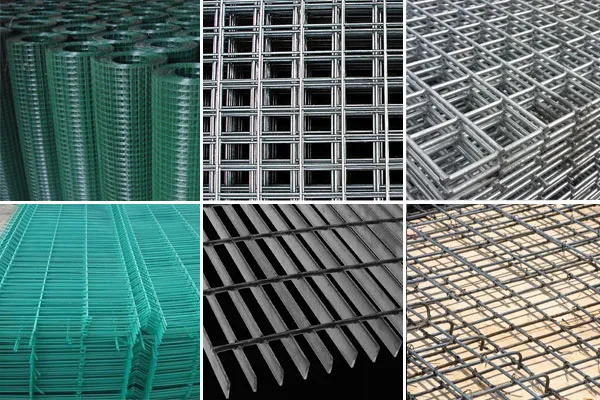

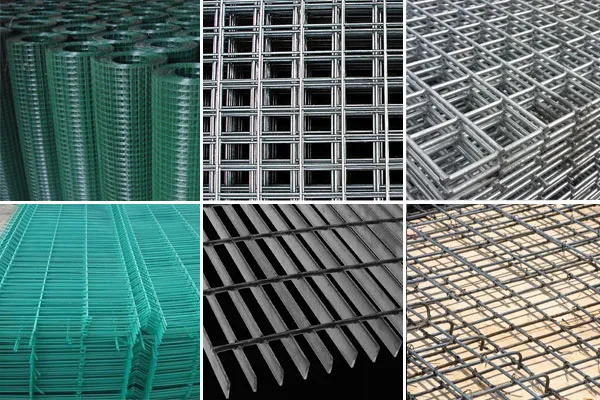

Welded Wire Mesh for Industry: Factory Supplier of Quality Mesh

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable, Versatile, Reliable Fencing Solution

NewsAug.14,2025