Aug . 13, 2024 05:46 Back to list

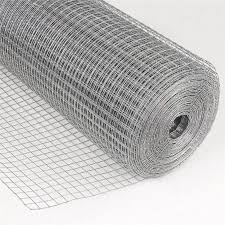

High-Quality 2mm Galvanized Wire from Reliable Manufacturers for Various Applications

Understanding Galvanized Wire The 2mm Factory Perspective

Galvanized wire has become a pivotal component across various industries, thanks to its durability, resistance to corrosion, and versatility. Among the various sizes and types of galvanized wire available in the market, 2mm galvanized wire is particularly favored for numerous applications, ranging from construction to agriculture. This article explores the significance of 2mm galvanized wire and sheds light on the manufacturing process from a factory perspective.

What is Galvanized Wire?

Galvanized wire is essentially steel wire that has undergone a galvanization process — a method of applying a protective zinc coating to steel or iron to prevent rusting. This process not only enhances the wire's lifespan but also significantly improves its strength. The thickness of the wire is measured in millimeters (mm), and 2mm galvanized wire is commonly used for its balanced attributes of strength, flexibility, and weight.

The Importance of 2mm Galvanized Wire

The 2mm galvanized wire is particularly important for various reasons

1. Strength and Durability The thickness of 2mm provides a solid framework that can withstand considerable tension and pressure, making it suitable for use in tensioned applications such as fencing, supporting structures, and mesh products.

3. Versatility The 2mm size makes this wire suitable for a myriad of applications. It can be used for tying plants, reinforcing concrete, making mesh fences, or creating wire baskets. Its adaptability has made it a staple in construction, gardening, and crafting industries.

galvanized wire 2mm factory

Manufacturing Process at the Factory

The production of 2mm galvanized wire involves several critical steps, ensuring that the final product meets the required standards of quality and performance.

1. Wire Drawing The process begins with wire drawing, where large coils of steel wire are progressively drawn through a series of dies to achieve the desired diameter. For 2mm wire, multiple passes through the dies are necessary to attain optimal uniformity and strength.

2. Cleaning Once the wire is drawn to size, it is thoroughly cleaned to remove any rust, oil, or scale. This step is crucial to ensure proper adhesion of the zinc coating.

3. Galvanization The cleaned wire then undergoes a galvanization process, usually through hot-dip galvanization. In this method, the wire is submerged in molten zinc, allowing for a robust coating that protects against corrosion. The thickness of the zinc layer can vary depending on the specific requirements, but industry standards typically ensure long-lasting protection.

4. Cooling and Coiling After galvanization, the wire is cooled and coiled into manageable sizes. Quality checks are performed to ascertain the uniformity of the coating and the integrity of the wire.

5. Packaging and Distribution Finally, the galvanized wire is packaged securely for distribution. Manufacturers often provide detailed specifications on the packaging, including weight, length, and tensile strength, to assist customers in their selection.

Conclusion

In summary, 2mm galvanized wire is an essential product in the market, highly valued for its strength, durability, and resistance to corrosion. The manufacturing process, from wire drawing to galvanization, plays a crucial role in delivering a high-quality end product. As industries continue to evolve, the demand for dependable materials like 2mm galvanized wire is likely to grow, making it an integral part of construction, agriculture, and beyond. Through understanding its characteristics and production methods, we can appreciate the value it adds to our lives and the industries it serves.

-

Chain Link Fence - Anping County Puersen | Durable, Versatile Fencing

NewsAug.15,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable Security&Wire Mesh

NewsAug.15,2025

-

Chain Link Fence: Durable & Versatile Security Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.15,2025

-

Chain Link Fence-Durable&Versatile|Anping County Puersen

NewsAug.15,2025

-

Welded Wire Mesh for Industry: Factory Supplier of Quality Mesh

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable, Versatile, Reliable Fencing Solution

NewsAug.14,2025