Aug . 14, 2024 09:38 Back to list

High-Quality 10mm Steel Bar Welded Wire Mesh Production for Reliable Construction and Industrial Use

The Importance of 10mm Steel Bar Welded Wire Mesh in Construction

In the construction industry, materials play a crucial role in determining the durability, strength, and overall quality of structures. Among the various materials used in construction, 10mm steel bar welded wire mesh stands out due to its versatility, strength, and ease of use. This article explores the significance of this particular type of mesh, its manufacturing process, applications, and benefits.

Understanding Welded Wire Mesh

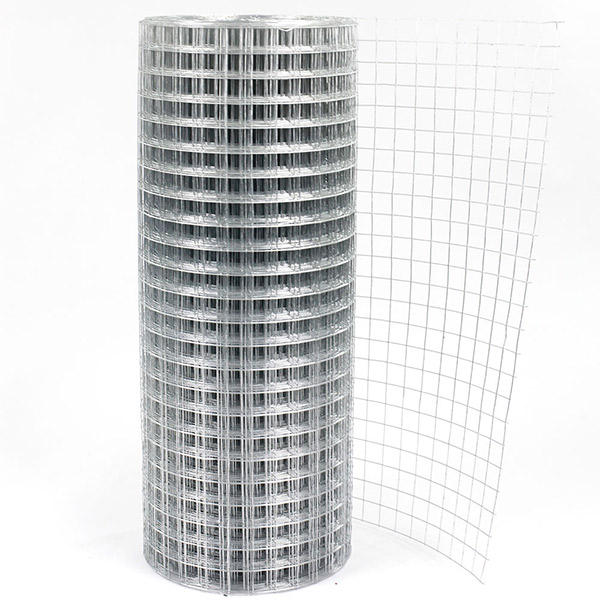

Welded wire mesh is comprised of a grid of steel wires that are welded together at their intersections, providing a uniform and robust structure. The designation 10mm refers to the diameter of the steel bars used in the mesh. This thickness offers a balance between flexibility and strength, making it ideal for a variety of construction applications. The wires are typically galvanized or coated with protective materials to resist corrosion, which enhances the longevity of the mesh.

Manufacturing Process

The manufacturing of 10mm steel bar welded wire mesh involves several stages. First, high-quality steel wire is procured, and then it is drawn down to the desired diameter. The next step is assembling the wires in a grid formation, where they are positioned at regular intervals. Once the grid is set, advanced welding machines apply heat to fuse the wires at their junctions. This process results in a rigid structure capable of bearing heavy loads. Finally, the mesh may undergo additional treatments such as galvanization or painting to enhance its durability against weather elements.

Applications in Construction

The versatility of 10mm steel bar welded wire mesh makes it suitable for numerous applications in the construction sector. One of its primary uses is in reinforced concrete structures. When embedded within concrete, the welded wire mesh provides added tensile strength, helping to prevent cracking and structural failure. This makes it an essential component in building foundations, slabs, walls, and pavements.

10mm steel bar welded wire mesh manufacturer

In addition to its use in structural reinforcement, this type of mesh is also employed in fencing, drainage systems, and agricultural applications. For instance, it can be used to create animal enclosures and garden fencing, providing a sturdy barrier against intruders while allowing for visibility and air circulation.

Benefits of Using 10mm Steel Bar Welded Wire Mesh

One of the most significant advantages of 10mm steel bar welded wire mesh is its strength-to-weight ratio. Despite being relatively lightweight, it can support heavy loads, which reduces the amount of concrete required in construction. This not only lowers costs but also facilitates easier handling and installation.

Moreover, welded wire mesh enhances the overall structural integrity of constructions. By distributing loads evenly, it minimizes the risk of localized failures, thus contributing to safer buildings. Its ease of installation also means that construction time is reduced, leading to faster project completion.

Furthermore, the durability of 10mm steel bar welded wire mesh cannot be overlooked. With proper treatment and maintenance, this material can withstand harsh weather conditions, chemical exposure, and physical wear, ensuring that buildings remain safe and intact for years to come.

Conclusion

In conclusion, 10mm steel bar welded wire mesh is an indispensable material in modern construction due to its strength, versatility, and cost-effectiveness. Its ability to enhance the durability of structures while providing ease of installation makes it a preferred choice among engineers and builders alike. As construction methods continue to evolve, the role of high-quality welded wire mesh will undoubtedly become even more prominent in the creation of safe and enduring structures.

-

High Quality Roll Welded Wire Mesh for Concrete Reinforcing BWG22 Galvanized Mesh Rolls Factory Direct

NewsJul.04,2025

-

High Quality Deformed Steel Bars China - Leading Manufacturers & Suppliers

NewsJul.04,2025

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025