Jul . 31, 2024 21:05 Back to list

High-Quality 10mm Steel Bar Welded Wire Mesh for Various Construction Applications and DIY Projects

The Essential Role of OEM 10mm Steel Bar Welded Wire Mesh in Construction

In the realm of construction and infrastructure development, the utilization of various materials is critical to ensure durability and strength. One such material that has gained prominence is the OEM 10mm steel bar welded wire mesh. This product is not only essential for the structural integrity of buildings but also plays a significant role in optimizing the construction process.

What is OEM 10mm Steel Bar Welded Wire Mesh?

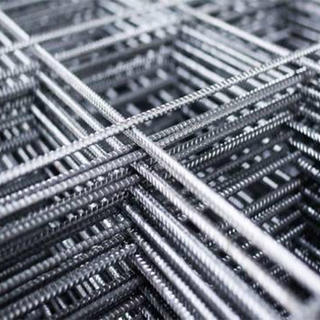

OEM stands for Original Equipment Manufacturer, referring to the production of goods that are used in another company's final product. In this context, OEM 10mm steel bar welded wire mesh is a heavy-duty mesh made from high-quality steel bars, each measuring 10mm in diameter, which are welded together at their intersections. This process creates a grid-like structure that provides excellent reinforcement, making it ideal for various construction applications.

Applications of Welded Wire Mesh in Construction

One of the primary applications of OEM 10mm steel bar welded wire mesh is in concrete reinforcement. Concrete, while strong in compression, is relatively weak in tension. The introduction of welded wire mesh provides the necessary tensile strength needed to resist cracking and structural failures. It is commonly used in floors, walls, and foundations, ensuring that the concrete can withstand various stresses during its lifespan.

Moreover, this type of mesh is highly versatile and can be utilized in diverse projects, ranging from residential buildings to large-scale infrastructure projects such as bridges and highways. Its adaptability makes it a preferred choice among contractors and construction engineers.

Advantages of Using OEM 10mm Steel Bar Welded Wire Mesh

oem 10mm steel bar welded wire mesh

1. Enhanced Strength and Durability The welded construction of the mesh ensures that it can withstand heavy loads and stresses, contributing to the overall strength of the concrete structure.

2. Ease of Use OEM welded wire mesh is easy to handle and install, which can significantly speed up the construction process. Its lightweight nature, combined with its robust design, allows for quick placement within framework structures.

3. Cost-Effective By reducing the amount of concrete needed and minimizing the risk of cracking, welded wire mesh can help lower material costs. Additionally, efficient installation reduces labor costs, making it an economical choice for builders.

4. Consistent Quality Being manufactured by an OEM means that the mesh adheres to strict quality standards. This consistency is crucial in construction where deviations can lead to vulnerabilities.

5. Sustainability Steel is a recyclable material, and the use of welded wire mesh can contribute to sustainable construction practices. By choosing products that can be reused or recycled, construction companies can minimize their environmental impact.

Conclusion

In summary, OEM 10mm steel bar welded wire mesh is a vital component in the construction industry. Its strength, durability, and versatility make it an indispensable choice for reinforcing concrete structures. As construction practices continue to evolve, the importance of high-quality materials such as welded wire mesh will undoubtedly remain at the forefront, enabling the creation of safe and sustainable buildings and infrastructure. The application of this technology not only facilitates superior construction outcomes but also signifies a move towards more efficient and economical building solutions. As we continue to build the future, incorporating robust materials like OEM welded wire mesh will be crucial in achieving our architectural goals.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025