Aug . 10, 2024 15:35 Back to list

High-Quality 100x100 Reinforcing Mesh for Construction Applications in China

Understanding China's 100x100 Reinforcing Mesh

In the realm of construction and civil engineering, reinforcing mesh plays a crucial role in ensuring the integrity and durability of concrete structures. One of the most widely utilized forms is the 100x100 reinforcing mesh, particularly popular in China due to its versatility and strength. This article explores the significance, applications, and manufacturing aspects of this essential construction material.

Definition and Composition

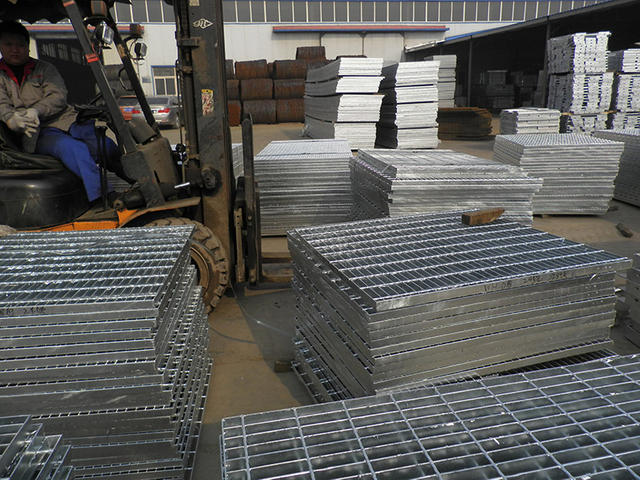

Reinforcing mesh, or welded wire mesh, consists of a grid formed by welding together longitudinal and transverse wires at regular intervals. The term 100x100 refers to the spacing between the wires, typically measured in millimeters, resulting in a grid that offers robust support for concrete. The mesh is usually made from high-quality carbon steel, which provides excellent tensile strength, making it suitable for various structural applications.

Importance in Construction

The primary purpose of 100x100 reinforcing mesh is to enhance the tensile strength of concrete, which inherently has high compressive strength but is weak under tension. This reinforcing mesh helps to distribute loads evenly, thereby minimizing the risk of cracking and structural failure. By integrating this mesh into concrete slabs, walls, and other forms, engineers can ensure that structures withstand environmental stresses and loads effectively.

Applications

The versatility of 100x100 reinforcing mesh makes it suitable for a myriad of applications

. It is commonly used in the construction ofchina 100x100 reinforcing mesh

1. Pavements Its grid structure helps in managing the stresses that arise from heavy traffic loads, preventing deformation and prolonging the lifespan of road surfaces. 2. Slabs In floor and roof slabs, this mesh provides the necessary reinforcement, ensuring that these critical components can support their intended loads without cracking.

3. Walls For both residential and commercial buildings, reinforcing mesh is often embedded in concrete walls, enhancing their strength and resistance against external forces, including winds and earthquakes.

4. Bridges The high tensile strength of this mesh makes it an ideal choice for bridge construction, where load-bearing capabilities are paramount.

Manufacturing Process

The production of 100x100 reinforcing mesh involves a series of meticulous steps to ensure quality and consistency. Initially, high-strength steel wire is drawn to the required diameter. Following this, the wires undergo a cold-welding process, where they are intersected and permanently fused together at specified intervals—100 mm in this case.

Once the mesh is produced, it goes through rigorous testing to ensure it meets national and international standards for strength and durability. These quality control measures ensure that the mesh can withstand the specific conditions it will be subjected to in construction projects. Moreover, surface treatments may be applied to enhance corrosion resistance, particularly in environments exposed to moisture or harmful chemicals.

Conclusion

The 100x100 reinforcing mesh is a fundamental material in modern construction, especially in China, where rapid urbanization and infrastructure development continue to rise. Its ability to enhance the structural performance and safety of concrete makes it indispensable across various applications. As the construction industry evolves, innovations in manufacturing processes and materials continue to emerge, further enhancing the capabilities of reinforcing mesh. A solid understanding of this product is essential for engineers, architects, and builders to ensure that the structures they create are safe, durable, and resilient in the face of changing environmental conditions.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025