Jun . 16, 2024 13:20 Back to list

Here are 10 short phrases that are similar to pvc welded wire mesh roll manufacturers 1. PVC mesh roll producers 2. Welded wire mesh suppliers 3. PVC woven netting manufacturers 4. Wire mesh roll mak

PVC Coated Welded Wire Mesh Rolls A Comprehensive Guide

Introduction

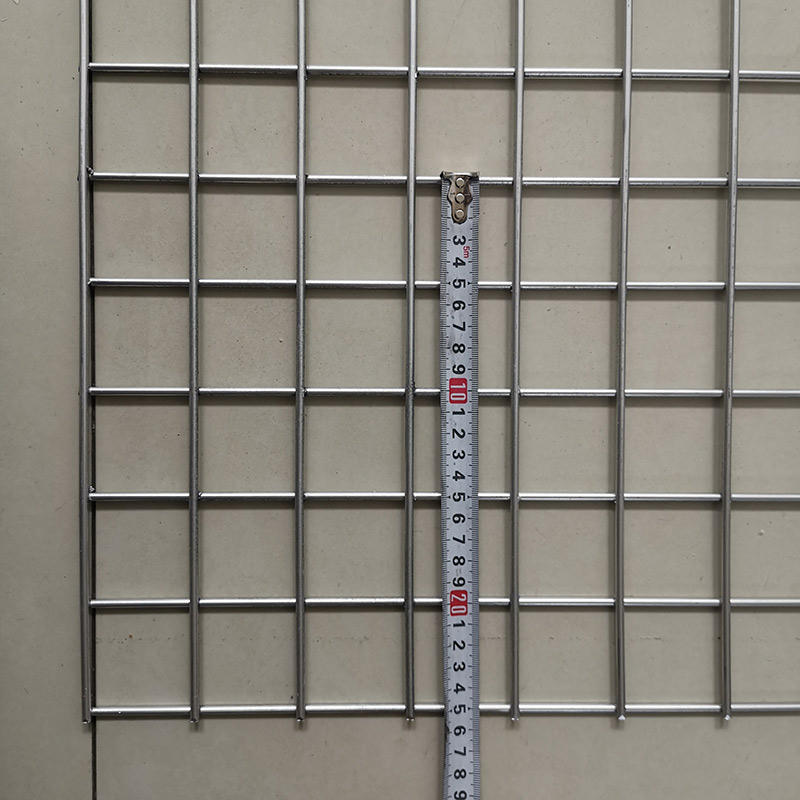

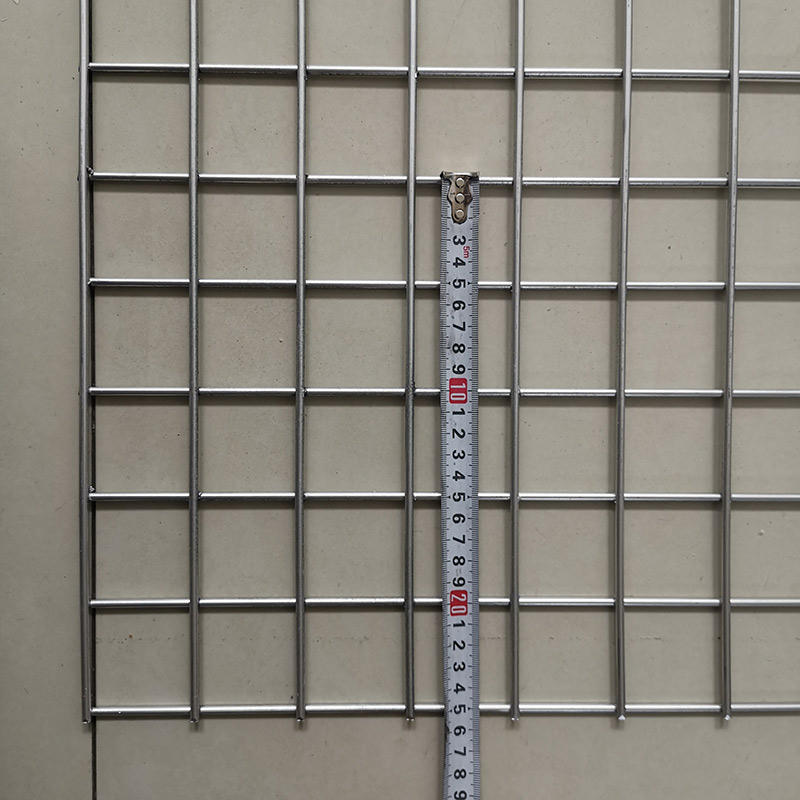

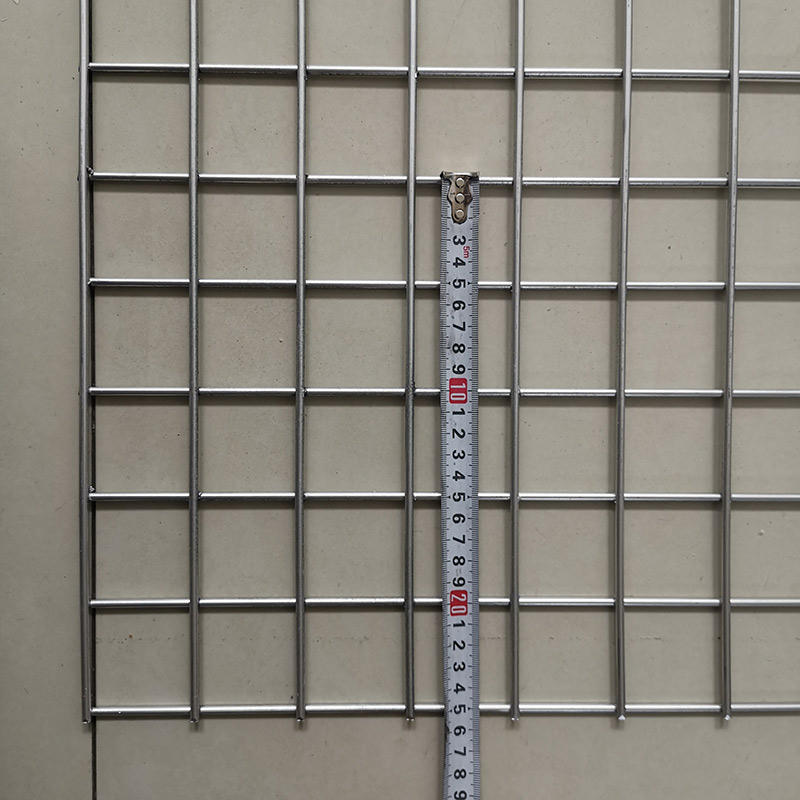

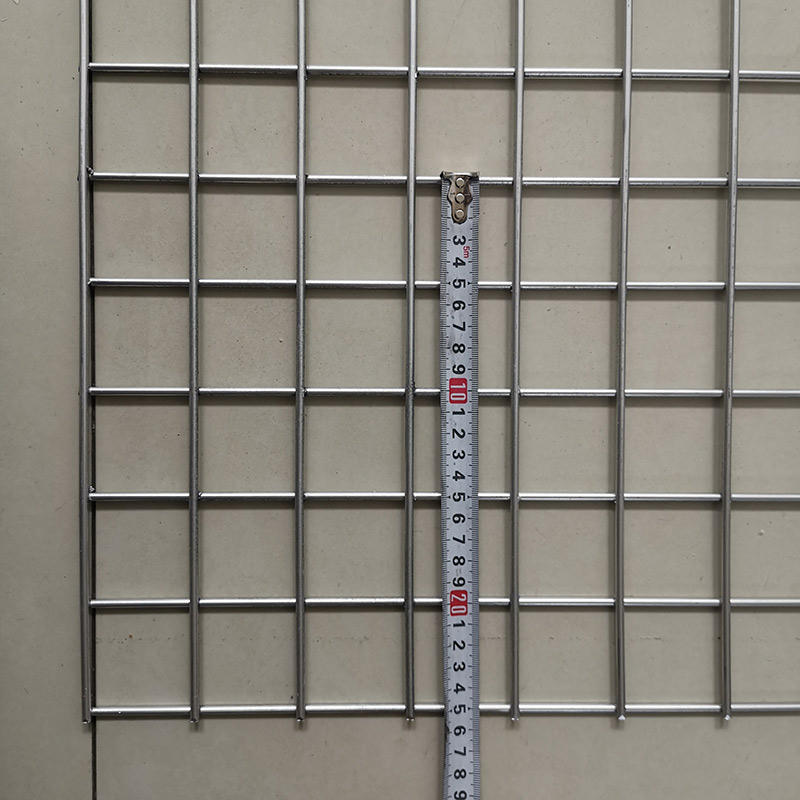

Welded wire mesh rolls are extensively used in various industries for their exceptional strength, durability, and versatility. These rolls consist of a grid of wires that are welded together at their intersections, creating a strong and rigid structure. One such popular type of welded wire mesh is the PVC coated welded wire mesh roll. This article provides an in-depth guide to PVC coated welded wire mesh rolls, including their properties, applications, and manufacturing process.

Properties of PVC Coated Welded Wire Mesh Rolls

1. Corrosion Resistance The PVC coating on these rolls provides excellent corrosion resistance, making them ideal for use in harsh environments where exposure to moisture, chemicals, and other corrosive substances is common.

2. Durability The welded wire mesh structure and PVC coating make these rolls highly durable and long-lasting, making them a popular choice for a wide range of applications.

3. Chemical Resistance PVC is resistant to many chemicals, making it suitable for use in applications where exposure to chemicals is likely.

4. UV Resistance The PVC coating also provides excellent UV resistance, ensuring that the rolls retain their color and integrity even after extended exposure to sunlight.

5. Easy Installation PVC coated welded wire mesh rolls are easy to install and can be cut to size as needed, making them a convenient choice for a variety of applications.

Applications of PVC Coated Welded Wire Mesh Rolls

1. Construction These rolls are commonly used in construction for fence panels, guardrails, and sound barriers.

2. Agriculture They are also used in agriculture for poultry netting, greenhouse covers, and hay bales.

3. Mining In the mining industry, these rolls are used for rock reinforcement and screening.

4

4 4

4

4

4 pvc welded wire mesh roll manufacturers. Chemical Industry They are used in the chemical industry for tank linings, filter bags, and conveyor belts.

5. Landscaping In landscaping, these rolls are used for ground cover, erosion control, and garden edging.

Manufacturing Process of PVC Coated Welded Wire Mesh Rolls

The manufacturing process of PVC coated welded wire mesh rolls involves several steps

1. Wire Drawing The first step is to draw the wires to the desired diameter and tolerance.

2. Welding The wires are then welded together at their intersections using a high-frequency welder.

3. Cleaning The welded wires are cleaned to remove any dirt or debris.

4. Coating The cleaned wires are then dipped into a PVC coating bath, which coats the wires evenly.

5. Drying The coated wires are then dried in an oven to remove any excess moisture.

6. Rolling Finally, the wires are rolled onto a spool or drum to create the final product.

Conclusion

PVC coated welded wire mesh rolls are a versatile and durable product with a wide range of applications. Their corrosion resistance, chemical resistance, and UV resistance make them ideal for use in harsh environments. The manufacturing process is straightforward and efficient, resulting in a high-quality product that is ready for immediate use. With their many benefits, PVC coated welded wire mesh rolls are sure to continue playing an important role in various industries for years to come.

pvc welded wire mesh roll manufacturers. Chemical Industry They are used in the chemical industry for tank linings, filter bags, and conveyor belts.

5. Landscaping In landscaping, these rolls are used for ground cover, erosion control, and garden edging.

Manufacturing Process of PVC Coated Welded Wire Mesh Rolls

The manufacturing process of PVC coated welded wire mesh rolls involves several steps

1. Wire Drawing The first step is to draw the wires to the desired diameter and tolerance.

2. Welding The wires are then welded together at their intersections using a high-frequency welder.

3. Cleaning The welded wires are cleaned to remove any dirt or debris.

4. Coating The cleaned wires are then dipped into a PVC coating bath, which coats the wires evenly.

5. Drying The coated wires are then dried in an oven to remove any excess moisture.

6. Rolling Finally, the wires are rolled onto a spool or drum to create the final product.

Conclusion

PVC coated welded wire mesh rolls are a versatile and durable product with a wide range of applications. Their corrosion resistance, chemical resistance, and UV resistance make them ideal for use in harsh environments. The manufacturing process is straightforward and efficient, resulting in a high-quality product that is ready for immediate use. With their many benefits, PVC coated welded wire mesh rolls are sure to continue playing an important role in various industries for years to come.

4

4

4

4 pvc welded wire mesh roll manufacturers. Chemical Industry They are used in the chemical industry for tank linings, filter bags, and conveyor belts.

5. Landscaping In landscaping, these rolls are used for ground cover, erosion control, and garden edging.

Manufacturing Process of PVC Coated Welded Wire Mesh Rolls

The manufacturing process of PVC coated welded wire mesh rolls involves several steps

1. Wire Drawing The first step is to draw the wires to the desired diameter and tolerance.

2. Welding The wires are then welded together at their intersections using a high-frequency welder.

3. Cleaning The welded wires are cleaned to remove any dirt or debris.

4. Coating The cleaned wires are then dipped into a PVC coating bath, which coats the wires evenly.

5. Drying The coated wires are then dried in an oven to remove any excess moisture.

6. Rolling Finally, the wires are rolled onto a spool or drum to create the final product.

Conclusion

PVC coated welded wire mesh rolls are a versatile and durable product with a wide range of applications. Their corrosion resistance, chemical resistance, and UV resistance make them ideal for use in harsh environments. The manufacturing process is straightforward and efficient, resulting in a high-quality product that is ready for immediate use. With their many benefits, PVC coated welded wire mesh rolls are sure to continue playing an important role in various industries for years to come.

pvc welded wire mesh roll manufacturers. Chemical Industry They are used in the chemical industry for tank linings, filter bags, and conveyor belts.

5. Landscaping In landscaping, these rolls are used for ground cover, erosion control, and garden edging.

Manufacturing Process of PVC Coated Welded Wire Mesh Rolls

The manufacturing process of PVC coated welded wire mesh rolls involves several steps

1. Wire Drawing The first step is to draw the wires to the desired diameter and tolerance.

2. Welding The wires are then welded together at their intersections using a high-frequency welder.

3. Cleaning The welded wires are cleaned to remove any dirt or debris.

4. Coating The cleaned wires are then dipped into a PVC coating bath, which coats the wires evenly.

5. Drying The coated wires are then dried in an oven to remove any excess moisture.

6. Rolling Finally, the wires are rolled onto a spool or drum to create the final product.

Conclusion

PVC coated welded wire mesh rolls are a versatile and durable product with a wide range of applications. Their corrosion resistance, chemical resistance, and UV resistance make them ideal for use in harsh environments. The manufacturing process is straightforward and efficient, resulting in a high-quality product that is ready for immediate use. With their many benefits, PVC coated welded wire mesh rolls are sure to continue playing an important role in various industries for years to come. Next:

Latest news

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025