Dec . 09, 2024 19:28 Back to list

Leading Manufacturers of High-Strength Drawn Steel Wire for Various Applications

Exploring Hard Drawn Steel Wire Manufacturers An Insight into Quality and Applications

Hard drawn steel wire is an essential component in various industries, offering remarkable strength, durability, and versatility. As manufacturers strive to cater to a wide range of applications, the production of hard drawn steel wire has become a focal point in the metalworking sector. This article delves into the characteristics of hard drawn steel wire, its manufacturing process, and the types of industries that rely on high-quality wire products.

Understanding Hard Drawn Steel Wire

Hard drawn steel wire is produced through a process of drawing steel wire through a series of dies, which reduces its diameter while increasing its strength. The process relies on cold drawing techniques, where the wire is pulled at room temperature, resulting in a tighter molecular structure. This enhancement in tensile strength is what makes hard drawn steel wire an ideal choice for applications that require increased resilience and endurance.

One of the crucial characteristics of hard drawn steel wire is its hardness, which refers to the wire’s ability to resist deformation. The hardness is achieved through controlled heat treatment processes that follow the drawing operation. As such, manufacturers can tailor the hardness and tensile properties of the wire to meet specific customer requirements.

The Manufacturing Process

The manufacturing of hard drawn steel wire involves several key steps

1. Wire Rod Production The process begins with the creation of wire rods made from high-quality steel. These rods serve as the raw material for producing hard drawn wire.

2. Wire Drawing In this critical phase, wire rods are drawn through a sequence of dies that reduce their diameter. The drawing process can be conducted in multiple stages and may involve lubricants to minimize friction and improve surface finish.

3. Annealing After drawing, the wire may undergo annealing, a heat treatment process that relieves internal stresses created during the drawing process. Annealing can help in achieving the desired balance between hardness and ductility.

4. Coiling and Packaging Once the drawing and treatment processes are complete, the hard drawn steel wire is coiled and packaged for distribution. Manufacturers ensure that the wire is stored properly to maintain its quality and prevent corrosion.

hard drawn steel wire manufacturers

5. Quality Control Leading manufacturers implement rigorous quality control measures to ensure that the final product meets industry standards. This includes testing for tensile strength, hardness, and surface integrity.

Industries That Rely on Hard Drawn Steel Wire

Hard drawn steel wire finds applications in various industries due to its robust nature and adaptability. Some of the key sectors that utilize this type of wire include

1. Construction Hard drawn steel wire is commonly used in reinforcing concrete, producing wire mesh, and manufacturing ties. Its strength helps ensure structural integrity in buildings and infrastructures.

2. Automotive The automotive industry employs hard drawn steel wire in manufacturing components such as springs, cables, and other critical parts that require high tensile strength.

3. Manufacturing Many manufacturers utilize hard drawn steel wire for creating machines, tools, and fasteners. Its durability makes it a preferred choice for components that undergo continuous stress and wear.

4. Fencing and Agriculture The wire is widely used in fencing applications due to its resistance to bending and pulling. In agriculture, it is used for creating trellises and support systems for crops.

5. Electronics Hard drawn steel wire is also prevalent in the electronics industry for creating connectors and mechanical parts that require precision and resilience.

Conclusion

Hard drawn steel wire manufacturers play a crucial role in supplying high-quality wire products that meet diverse industrial needs. Through a meticulously controlled manufacturing process, these manufacturers provide essential materials that enhance the strength and durability of various applications. As industries continue to evolve and demand more sophisticated materials, the importance of reliable hard drawn steel wire cannot be overstated. With ongoing advancements in manufacturing technologies, the future of hard drawn steel wire looks promising, ensuring its place as a fundamental element in modern-day engineering and construction.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

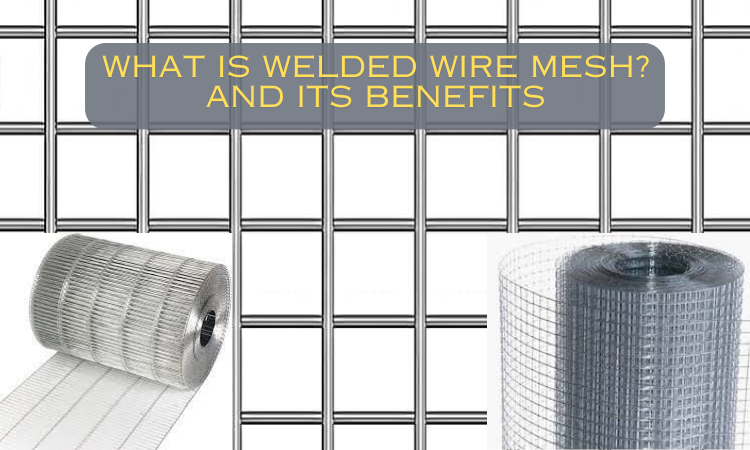

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025