Nov . 18, 2024 14:05 Back to list

High-Quality Drawn Steel Wire Manufacturing Facility for Strong and Durable Solutions

The Significance of Hard Drawn Steel Wire Production

Hard drawn steel wire is an essential material widely used in various applications, ranging from construction to manufacturing. The process of producing hard drawn steel wire is complex and requires significant technological expertise. A hard drawn steel wire factory plays a pivotal role in providing the market with high-quality wire that meets the demands of different industries.

The first step in the production of hard drawn steel wire involves selecting the appropriate raw materials. Typically, steel rods are chosen for their strength and durability. The selection process is crucial, as the quality of the raw material directly influences the characteristics of the final product. Once the steel rods have been procured, they are subjected to a series of processes that include heating, drawing, and cooling.

Drawing is the heart of the production process. In this stage, the steel rods are pulled through a series of dies to reduce their diameter and increase their length. This process not only alters the physical dimensions of the wire but also enhances its tensile strength. As the wire is drawn, it undergoes significant deformation, which aligns the grains of the steel and improves its mechanical properties. This transformation results in a wire that is strong, resilient, and suitable for a variety of applications.

hard drawn steel wire factory

The hardening process is another critical phase in the factory. After the wire has been drawn to the desired specifications, it is often subjected to heat treatment, which further improves its hardness. This treatment involves heating the wire to a specific temperature and then cooling it rapidly. The method of hardening can vary based on the desired characteristics of the wire. The careful control of the heating and cooling process ensures that the wire achieves the necessary hardness while retaining its ductility.

Quality control is integral to the operations of a hard drawn steel wire factory. Rigorous testing is conducted to ensure that the wire meets industry standards and customer specifications. This includes checking for tensile strength, elongation, and surface quality. Factories often utilize advanced testing equipment to ensure that the wire produced is reliable and safe for use in demanding applications.

In addition to the technical aspects, sustainability has become a significant focus for modern hard drawn steel wire factories. Many manufacturers are adopting eco-friendly practices, such as recycling scrap metal and reducing energy consumption during production. These initiatives not only help minimize the environmental impact but also contribute to the overall efficiency of the manufacturing process.

In conclusion, hard drawn steel wire factories play a fundamental role in the supply chain of numerous industries. Through advanced techniques and stringent quality control measures, these factories ensure the production of high-quality wire that meets the diverse needs of their customers. As technology advances and sustainability becomes increasingly important, the future of hard drawn steel wire production is poised for innovation and growth.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

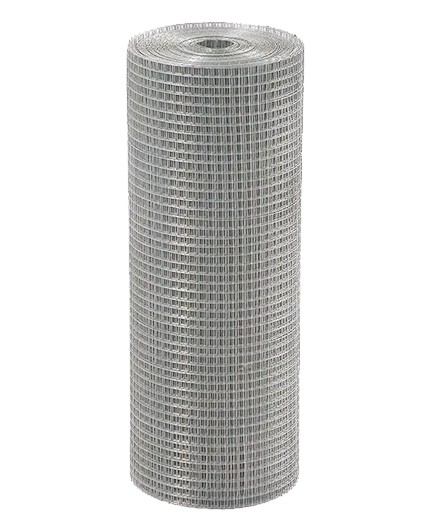

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025