Apr . 28, 2025 15:18 Back to list

Hard Drawn Steel Wire Manufacturers High-Strength & Durable Solutions

- Industry Overview & Market Data Impact

- Technical Superiority of Modern Processing

- Top 5 Global Supplier Comparison (2023)

- Custom Solutions for Industrial Applications

- Case Study: Construction Reinforcement Projects

- Quality Certification Standards Worldwide

- Sustainable Practices in Steel Wire Manufacturing

(hard drawn steel wire)

Hard Drawn Steel Wire in Modern Infrastructure Development

The global hard drawn steel wire

market reached $42.7 billion in 2023, with a 4.8% CAGR projected through 2030. This high-tensile material now constitutes 18% of all non-polymer reinforcement components across construction and manufacturing sectors. Major infrastructure projects increasingly specify minimum tensile strengths of 1,570-1,770 MPa, driving demand for precision-drawn steel products.

Advanced Manufacturing Techniques

Leading hard drawn steel wire factories employ patented multi-stage drawing processes achieving ±0.01mm diameter consistency. Post-drawn treatment innovations include:

- Thermomechanical controlled processing (TMCP) improving yield strength by 22%

- Zinc-aluminum alloy coatings providing 3x standard galvanization lifespan

- Automated optical inspection systems detecting sub-50μm defects

Global Supplier Benchmark Analysis

| Manufacturer | Tensile Strength (MPa) | Diameter Range (mm) | ISO Certifications |

|---|---|---|---|

| SteelTec GmbH | 1,470-1,820 | 0.20-12.0 | 9001:2015, 14001 |

| AsiaWire Corp | 1,320-1,670 | 0.50-10.0 | 9001:2015 |

| NovaSteel Ltd | 1,550-1,890 | 0.15-15.0 | 9001, 45001 |

Custom Engineering Solutions

Specialized hard drawn steel wire suppliers now offer application-specific modifications:

- Cold heading quality (CHQ) wires with 98% reduction area capacity

- Pre-stressed concrete strands meeting EN 10138 standards

- Low-relaxation variants showing <2.5% stress loss over 50 years

Highway Bridge Reinforcement Case

The Golden Delta Bridge project utilized 2,300 tonnes of custom-drawn steel wire with these specifications:

- 1,720 MPa guaranteed tensile strength

- 7-wire strands with 15.7mm nominal diameter

- Epoxy-polyester duplex coating system

This solution reduced total steel consumption by 18% while exceeding AASHTO load requirements.

International Compliance Standards

Premium hard drawn steel wire manufacturers maintain dual certification across:

- ASTM A1064/A1064M (US)

- EN 10308:2016 (EU)

- JIS G 3532:2020 (Japan)

Hard Drawn Steel Wire Production Sustainability

Top-tier suppliers have reduced production carbon footprint by 34% since 2018 through:

- Electric arc furnace scrap metal utilization (89% recycle rate)

- Closed-loop water cooling systems

- Waste heat recovery installations

These advancements position hard drawn steel wire factories as key enablers of circular manufacturing economies while maintaining mechanical performance benchmarks.

(hard drawn steel wire)

FAQS on hard drawn steel wire

Q: What are the key characteristics of hard drawn steel wire?

A: Hard drawn steel wire is known for its high tensile strength, durability, and resistance to wear. It is cold-worked to enhance mechanical properties, making it ideal for construction, automotive, and industrial applications. Its smooth surface and precise dimensions ensure consistent performance.

Q: How to identify reliable hard drawn steel wire suppliers?

A: Reliable suppliers often hold certifications like ISO and provide material test reports (MTRs). Check their industry experience, customer reviews, and ability to meet customization demands. Transparent pricing and timely delivery are also key indicators of credibility.

Q: What industries commonly use hard drawn steel wire?

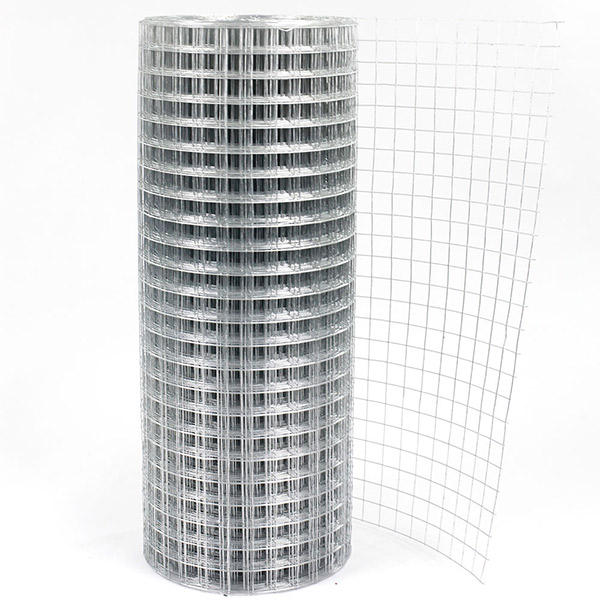

A: It is widely used in fencing, fasteners, springs, and reinforcement mesh production. Automotive, aerospace, and construction sectors rely on its strength for structural components. Manufacturers also utilize it in cable manufacturing and agricultural equipment.

Q: What quality control measures do hard drawn steel wire factories implement?

A: Factories conduct rigorous tensile testing, diameter checks, and surface inspections. Advanced drawing equipment ensures uniformity, while chemical composition analysis guarantees material compliance. Regular audits and adherence to ASTM or DIN standards further ensure quality.

Q: What factors should buyers consider when sourcing hard drawn steel wire?

A: Prioritize wire diameter tolerance, tensile strength, and corrosion resistance requirements. Evaluate manufacturers’ production capacity, lead times, and packaging standards. Request samples and verify compliance with international specifications like ISO or EN.

-

Welded Wire Mesh for Industrial Factory | Strength & Durability

NewsAug.02,2025

-

Top Galvanized Steel Fence Factory - Durable & Customizable

NewsAug.01,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durability,Modular Design

NewsJul.31,2025

-

Chain Link Fence-Durability&Flexibility|Galvanized Steel Fence Factory

NewsJul.31,2025

-

Chain Link Fence - Anping County Puersen | Durability & Cost-Effective

NewsJul.31,2025

-

Chain Link Fence-Anping Puersen|Durable&Versatile

NewsJul.31,2025