Nov . 08, 2024 00:30 Back to list

4mm Gi Wire Manufacturers For Reliable Quality and Competitive Pricing Options

The Importance of 4mm GI Wire Factories in Modern Industries

In today's industrial landscape, the demand for high-quality materials is paramount. One such material that has gained significant traction is galvanized iron (GI) wire, particularly the 4mm variant. This article explores the importance of 4mm GI wire factories, their production processes, and their critical role across various sectors.

Understanding GI Wire

Galvanized iron wire is produced by coating iron or steel with a layer of zinc to prevent rust and corrosion. The process of galvanization enhances the wire's durability and makes it suitable for a wide range of applications. Among the various sizes available, 4mm GI wire strikes a balance between strength and flexibility, making it ideal for construction, fencing, agricultural use, and even artistic projects.

Production Process of 4mm GI Wire

The manufacturing of 4mm GI wire involves several key steps, all performed within specialized factories. First, high-quality steel rods are drawn down to the desired diameter of 4mm using wire drawing machines. These machines ensure that the wire is uniform and meets strict quality standards. After drawing, the wire undergoes a cleaning process to remove any impurities that might affect the galvanization quality.

Following this, the wire is subjected to a galvanization process, typically through hot-dip galvanization. In this method, the clean wire is immersed in molten zinc, allowing a robust zinc coating to form on the surface. This layer provides exceptional corrosion resistance, which is vital for extending the life of the wire in various environmental conditions.

Once the galvanization process is complete, the wire is cooled, cut, and packaged for distribution. Factories may also conduct quality control assessments at various stages to ensure that the final product meets industry standards.

Applications of 4mm GI Wire

gi wire 4mm factories

4mm GI wire is incredibly versatile, finding applications in various sectors. In construction, it is often used for binding materials, ensuring structural integrity, and reinforcing concrete. Fencing is another significant application, as the strength of 4mm GI wire makes it an excellent choice for agricultural, residential, and commercial fencing solutions.

Agriculturally, the wire supports plant growth through trellises or can be used to protect crops from animals. The construction industry also employs 4mm GI wire in scaffolding and formwork, where its strength and resistance to environmental factors are invaluable.

Moreover, in the arts and crafts sector, its malleability allows artists to create intricate designs and structures, showcasing the wire's versatility beyond traditional industrial uses.

Economic Significance of GI Wire Factories

The establishment and operation of 4mm GI wire factories contribute significantly to the economy. They create numerous job opportunities, from manufacturing to administrative roles. Moreover, local factories reduce dependency on imported wire, which can be subject to tariffs and fluctuating prices, ultimately benefiting the local economy.

Furthermore, with the growing trend towards sustainable practices, many factories are adopting eco-friendly methods in their production processes. This shift not only helps in reducing environmental impact but also appeals to increasingly environmentally-conscious consumers.

Conclusion

In conclusion, 4mm GI wire factories play a crucial role in modern industries, providing a vital product that meets the needs of various sectors. The combination of strength, flexibility, and resistance to corrosion makes 4mm GI wire an indispensable material in construction, agriculture, and more. As demand for quality materials continues to grow, the significance of these factories will only increase, driving innovation and economic growth in the process. The commitment to quality and sustainability within the industry paves the way for a robust future for both manufacturers and consumers alike.

-

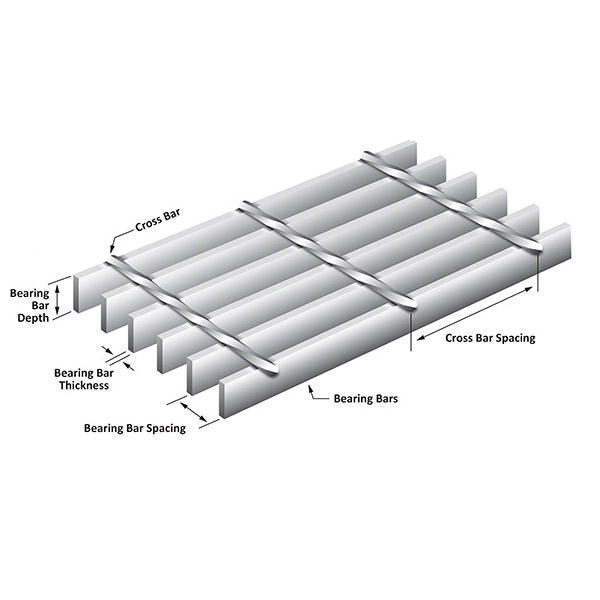

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025