Nov . 08, 2024 17:37 Back to list

gi wire 4mm factories

The Rise of 4mm GI Wire Factories A Comprehensive Overview

In recent years, the demand for galvanized iron (GI) wire has witnessed a significant surge, driven by the increased need for sturdy, rust-resistant materials in various construction and industrial applications. One of the key players in this market is the 4mm GI wire, prized for its durability and versatility. As a result, factories specializing in the production of 4mm GI wire have proliferated, catering to both local and international markets.

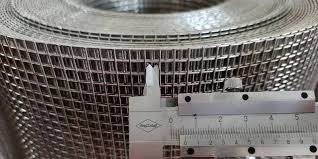

Galvanized iron wire is produced by coating iron or steel wire with a thin layer of zinc to protect it from corrosion. The galvanization process involves either hot-dip galvanization or electro-galvanization, both of which enhance the lifespan of the wire. Among various sizes, the 4mm GI wire is particularly favored for its balance of strength and flexibility, making it suitable for a wide range of applications, from fencing and construction to agriculture and manufacturing.

The Rise of 4mm GI Wire Factories A Comprehensive Overview

Another significant factor contributing to the growth of 4mm GI wire factories is technological advancements. Modern manufacturing processes have streamlined production, optimizing efficiency and reducing costs. Innovations in galvanization techniques have also improved the quality of the wire, ensuring greater resistance to environmental factors. As factories adopt these advanced technologies, they are able to produce high-quality products at competitive prices, which is crucial in a market where competition is fierce.

gi wire 4mm factories

Moreover, the environmental impact of production processes is becoming increasingly important. Many new GI wire factories are focusing on sustainable practices, such as minimizing waste and utilizing energy-efficient machinery. This not only helps in reducing the ecological footprint but also appeals to environmentally conscious consumers and businesses. As a result, factories that adopt these practices can enhance their market appeal while contributing to global sustainability efforts.

In addition to local markets, 4mm GI wire factories are eyeing international export opportunities. The global demand for this versatile wire is significant, particularly in developing countries where infrastructural growth is a priority. By ensuring compliance with international standards and quality certifications, factories can tap into lucrative markets, expanding their reach and increasing revenue.

However, the Gi wire industry does not come without its challenges. Fluctuating raw material prices, particularly of steel and zinc, can impact production costs significantly. Moreover, competition from manufacturers in countries with lower production costs poses a threat to profitability for many factories. To stay ahead, businesses must innovate continuously, exploring new markets and diversifying their product offerings.

In conclusion, the rise of 4mm GI wire factories is a reflection of the growing demand for durable and reliable materials in various sectors. As the construction and agricultural industries continue to expand, the need for high-quality GI wire is set to increase further. By leveraging technological advancements and adopting sustainable practices, these factories can not only meet domestic needs but also thrive in the global marketplace. The future looks promising for the 4mm GI wire manufacturing industry, provided that these factories can navigate the challenges that lie ahead.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025