Dec . 04, 2024 00:47 Back to list

GI Welded Wire Mesh Production Facility Overview and Insights for Quality Standards

The Importance of GI Welded Wire Mesh An Overview of the Manufacturing Process

In the construction and manufacturing industries, the demand for durable, versatile, and cost-effective materials is ever-increasing. Among these materials, galvanized iron (GI) welded wire mesh has gained significant popularity due to its robustness, corrosion resistance, and numerous applications across various sectors. This article delves into the pivotal role of GI welded wire mesh factories, focusing on the manufacturing process and the advantages of this essential construction material.

Understanding GI Welded Wire Mesh

GI welded wire mesh is made by welding together wires at their intersections, resulting in a grid-like structure that offers excellent strength and stability. The galvanized aspect refers to the protective zinc coating applied to the iron wires, which acts as a barrier against rust and environmental factors. As a result, GI welded wire mesh is particularly useful in settings where exposure to moisture and other corrosive elements is a concern.

Manufacturing Process

The production of GI welded wire mesh involves several key steps

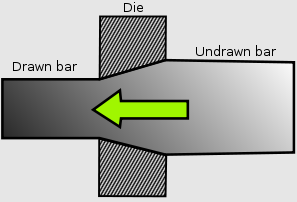

1. Wire Drawing This initial stage involves drawing the raw steel wires through a series of dies to achieve the desired thickness. The diameter of the wire can vary depending on the intended application, ranging from thin strands for delicate tasks to thicker wires for heavy-duty use.

2. Galvanization Once the wires have been drawn, they undergo a galvanization process. This typically involves either hot-dip galvanization, where the wires are submerged in molten zinc, or electro-galvanization, which applies a zinc coating through an electrochemical process. Hot-dip galvanization offers superior protection and is often favored for outdoor and heavy-use applications.

3. Welding After galvanization, the wires are cut to the appropriate lengths and arranged in a grid pattern. Automated welding machines are then used to weld the wires at their intersecting points, creating a sturdy mesh structure. The welding process is crucial, as it ensures that the mesh can withstand significant tensile and compressive forces.

4. Finishing The final stage of production involves trimming, cleaning, and inspecting the welded wire mesh for any defects. Additional treatments, such as painting or coating, may be applied for aesthetic purposes or extra protection against corrosion.

Applications of GI Welded Wire Mesh

GI welded wire mesh exhibits a wide range of applications across different industries

gi welded wire mesh factory

- Construction It is widely used in the construction of buildings, especially for reinforcing concrete structures, creating fences, and forming barriers

. The mesh enhances the tensile strength of concrete, reducing the risk of cracking.- Agriculture Farmers utilize GI welded wire mesh for fencing livestock, creating garden enclosures, and supporting plants. Its durability ensures long-lasting protection against pests and predators.

- Industrial Use In industrial settings, it is used for safety barriers, grid flooring, and storage racks. The strength and versatility of GI welded wire mesh make it ideal for heavy-duty applications.

- Infrastructure The mesh is also employed in the construction of bridges, highway barriers, and other structural components, providing essential support and safety features.

Advantages of GI Welded Wire Mesh

The benefits of using GI welded wire mesh are numerous

- Durability The galvanized coating offers long-lasting protection against rust and corrosion, making it suitable for various environments.

- Versatility It can be customized to meet specific size and strength requirements, accommodating a diverse range of applications.

- Cost-Effectiveness Compared to other reinforcing materials, GI welded wire mesh is relatively affordable, making it a popular choice for both small and large projects.

- Ease of Installation The lightweight nature of the mesh allows for easy handling and installation, reducing labor costs and time.

In conclusion, GI welded wire mesh factories play a crucial role in producing this essential construction material, which offers numerous advantages across various industries. As demands for sustainable and durable building solutions continue to rise, the importance of such factories and the products they manufacture will only grow. Understanding the manufacturing process and the applications of GI welded wire mesh can help stakeholders make informed decisions, ultimately contributing to more resilient and efficient construction practices.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025