Nov . 09, 2024 17:28 Back to list

GI Welded Wire Mesh Manufacturing Facility Overview and Production Insights

The Importance of High-Quality GI Welded Wire Mesh in Modern Construction

Galvanized Iron (GI) welded wire mesh has become an indispensable material in the construction industry, offering a blend of strength, durability, and versatility. As the demand for innovative building solutions continues to rise, the role of reliable manufacturers of GI welded wire mesh is more critical than ever. This article examines the benefits of GI welded wire mesh, the manufacturing process, and highlights the importance of sourcing from reputable factories.

Understanding GI Welded Wire Mesh

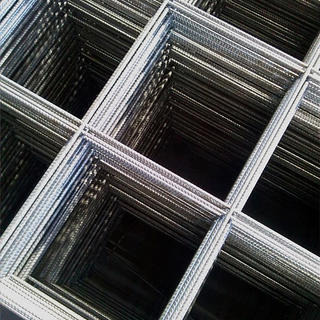

GI welded wire mesh is composed of a grid of steel wires that are welded together at their intersections, then galvanized to protect against corrosion. This method of construction offers enhanced structural integrity compared to other types of wire mesh. The galvanization process involves coating the wire with zinc, which acts as a barrier to moisture and corrosive elements, thereby extending the lifespan of the mesh.

Benefits of GI Welded Wire Mesh

1. Strength and Durability One of the most significant advantages of GI welded wire mesh is its high tensile strength. The welding process ensures that the intersecting wires are tightly fused together, making it exceptionally robust and capable of bearing heavy loads. This strength is especially crucial in applications such as reinforcing concrete slabs and walls, where structural integrity is paramount.

2. Corrosion Resistance The galvanization process provides an effective protective layer against rust and moisture, enabling GI welded wire mesh to withstand harsh environmental conditions. This quality makes it suitable for both indoor and outdoor usage, including agricultural, industrial, and residential applications.

3. Versatile Applications GI welded wire mesh can serve a wide array of functions. It is frequently used for reinforcing concrete, fencing, and creating barriers or cages for animals. Additionally, it finds applications in landscaping and erosion control, providing support for plants while preventing soil erosion.

4. Cost-Effective Solution While the upfront cost of GI welded wire mesh may be higher than that of non-galvanized wire, its longevity and low maintenance requirements translate into significant cost savings over time. Investing in high-quality mesh can reduce the need for replacements and repairs, ultimately leading to lower overall project costs.

The Manufacturing Process

gi welded wire mesh factory

The production of high-quality GI welded wire mesh involves several key steps. First, high-grade steel wire is sourced and drawn into the desired diameter. The wires are then arranged in a predetermined grid pattern, where they are meticulously welded at their intersections. After welding, the mesh undergoes a galvanization process, where it is either hot-dipped or electroplated with zinc.

Reliable factories pay great attention to quality control throughout the manufacturing process. This includes testing the strength of the wire, inspecting the weld quality, and ensuring uniformity in mesh dimensions. Such stringent quality measures ensure that the final product meets industry standards and customer expectations.

Choosing a Reputable Manufacturer

When selecting a factory for GI welded wire mesh, it is vital to consider several factors

1. Experience and Reputation Choosing a manufacturer with a proven track record in the industry guarantees access to high-quality products. Researching customer reviews and testimonials can provide insight into the factory’s reliability.

2. Quality Certifications Look for manufacturers that hold relevant certifications such as ISO 9001, which indicates adherence to international quality management standards.

3. Customization Options A good factory should offer customization in terms of wire gauge, mesh size, and galvanization types to meet specific project requirements.

4. After-sales Support Strong post-purchase support is essential. Choose a manufacturer that provides assistance with installation, maintenance guidance, and handles any concerns post-delivery.

Conclusion

In conclusion, GI welded wire mesh is a critical component in modern construction, providing strength, durability, and versatility for various applications. Sourcing from reputable factories ensures access to high-quality materials that meet specific project needs. As construction technology evolves, the significance of reliable GI welded wire mesh cannot be overstated, as it lays the foundation for safe and enduring structures.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025