Jun . 13, 2024 15:50 Back to list

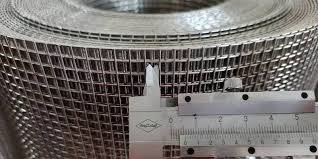

GI welded wire mesh refers to galvanized iron welded mesh.

Understanding the Significance of GI Welded Wire Mesh in Modern Construction

GI Welded Wire Mesh, a staple in contemporary construction and engineering, is a versatile and robust material that has revolutionized the way structures are built. The term GI stands for Galvanized Iron, a process where steel is coated with a layer of zinc to provide corrosion resistance. This combination of steel's strength and zinc's protective qualities makes the mesh an ideal choice for various applications.

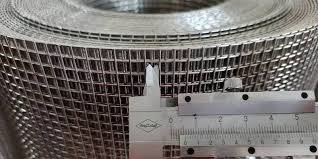

Welded wire mesh, as the name suggests, is created by welding individual wires together at intersections, forming a grid-like pattern. This method ensures a strong, uniform structure with consistent spacing and dimensions, which is crucial in many construction processes. The GI coating further enhances its durability, making it resistant to rust and weathering, particularly in outdoor or damp environments.

The use of GI welded wire mesh in construction is widespread due to its numerous advantages. In concrete reinforcement, it provides an even distribution of stress, enhancing the structural integrity of floors, walls, and foundations. Its pre-fabricated nature simplifies the installation process, reducing labor costs and time spent on site. Moreover, the mesh's open design allows for better concrete pouring and compaction, leading to stronger and more durable structures.

In addition to construction, GI welded wire mesh finds application in agriculture, where it is used for fencing, animal enclosures, and plant support systems

In addition to construction, GI welded wire mesh finds application in agriculture, where it is used for fencing, animal enclosures, and plant support systems In addition to construction, GI welded wire mesh finds application in agriculture, where it is used for fencing, animal enclosures, and plant support systems

In addition to construction, GI welded wire mesh finds application in agriculture, where it is used for fencing, animal enclosures, and plant support systems

In addition to construction, GI welded wire mesh finds application in agriculture, where it is used for fencing, animal enclosures, and plant support systems

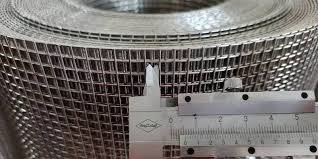

In addition to construction, GI welded wire mesh finds application in agriculture, where it is used for fencing, animal enclosures, and plant support systems gi welded wire mesh. Its rust-resistant properties make it suitable for both indoor and outdoor use, ensuring long-term functionality.

Furthermore, the mesh is also utilized in industrial settings for safety barriers, machine guards, and storage cages, providing a balance between security and visibility. Its versatility extends to the manufacturing sector, where it is employed in the production of various products, from sieves and filters to automotive parts.

The significance of GI welded wire mesh lies not only in its strength and resilience but also in its environmental sustainability. The recyclability of both steel and zinc ensures minimal waste and a reduced carbon footprint, aligning with the growing emphasis on eco-friendly practices.

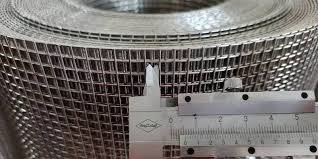

In conclusion, GI welded wire mesh is a testament to the fusion of engineering innovation and practicality. Its durability, ease of installation, and wide range of applications make it an indispensable component in modern construction and beyond. As technology advances, we can expect further developments in the production and usage of this versatile material, solidifying its position in the global construction industry.

gi welded wire mesh. Its rust-resistant properties make it suitable for both indoor and outdoor use, ensuring long-term functionality.

Furthermore, the mesh is also utilized in industrial settings for safety barriers, machine guards, and storage cages, providing a balance between security and visibility. Its versatility extends to the manufacturing sector, where it is employed in the production of various products, from sieves and filters to automotive parts.

The significance of GI welded wire mesh lies not only in its strength and resilience but also in its environmental sustainability. The recyclability of both steel and zinc ensures minimal waste and a reduced carbon footprint, aligning with the growing emphasis on eco-friendly practices.

In conclusion, GI welded wire mesh is a testament to the fusion of engineering innovation and practicality. Its durability, ease of installation, and wide range of applications make it an indispensable component in modern construction and beyond. As technology advances, we can expect further developments in the production and usage of this versatile material, solidifying its position in the global construction industry.

In addition to construction, GI welded wire mesh finds application in agriculture, where it is used for fencing, animal enclosures, and plant support systems

In addition to construction, GI welded wire mesh finds application in agriculture, where it is used for fencing, animal enclosures, and plant support systems

In addition to construction, GI welded wire mesh finds application in agriculture, where it is used for fencing, animal enclosures, and plant support systems

In addition to construction, GI welded wire mesh finds application in agriculture, where it is used for fencing, animal enclosures, and plant support systems gi welded wire mesh. Its rust-resistant properties make it suitable for both indoor and outdoor use, ensuring long-term functionality.

Furthermore, the mesh is also utilized in industrial settings for safety barriers, machine guards, and storage cages, providing a balance between security and visibility. Its versatility extends to the manufacturing sector, where it is employed in the production of various products, from sieves and filters to automotive parts.

The significance of GI welded wire mesh lies not only in its strength and resilience but also in its environmental sustainability. The recyclability of both steel and zinc ensures minimal waste and a reduced carbon footprint, aligning with the growing emphasis on eco-friendly practices.

In conclusion, GI welded wire mesh is a testament to the fusion of engineering innovation and practicality. Its durability, ease of installation, and wide range of applications make it an indispensable component in modern construction and beyond. As technology advances, we can expect further developments in the production and usage of this versatile material, solidifying its position in the global construction industry.

gi welded wire mesh. Its rust-resistant properties make it suitable for both indoor and outdoor use, ensuring long-term functionality.

Furthermore, the mesh is also utilized in industrial settings for safety barriers, machine guards, and storage cages, providing a balance between security and visibility. Its versatility extends to the manufacturing sector, where it is employed in the production of various products, from sieves and filters to automotive parts.

The significance of GI welded wire mesh lies not only in its strength and resilience but also in its environmental sustainability. The recyclability of both steel and zinc ensures minimal waste and a reduced carbon footprint, aligning with the growing emphasis on eco-friendly practices.

In conclusion, GI welded wire mesh is a testament to the fusion of engineering innovation and practicality. Its durability, ease of installation, and wide range of applications make it an indispensable component in modern construction and beyond. As technology advances, we can expect further developments in the production and usage of this versatile material, solidifying its position in the global construction industry. Latest news

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025