Nov . 22, 2024 08:26 Back to list

galvanized wire factories

The Role of Galvanized Wire Factories in Modern Industry

Galvanized wire, celebrated for its durability and resistance to corrosion, plays a vital role in various industries, from construction to agriculture. The process of galvanization involves coating iron or steel wire with a layer of zinc to enhance its longevity and performance in harsh environments. This article explores the significance of galvanized wire factories, their production processes, and their contributions to modern industrial practices.

Understanding Galvanization

The galvanization process is essential for protecting metal surfaces from rust and corrosion. By applying a zinc coating, the underlying iron or steel is safeguarded from moisture and environmental elements. This protective layer significantly prolongs the life of the wire, reducing the need for frequent replacements and maintenance. As a result, galvanized wire becomes a cost-effective solution for numerous applications.

Key Applications of Galvanized Wire

Galvanized wire is widely used in various sectors, including

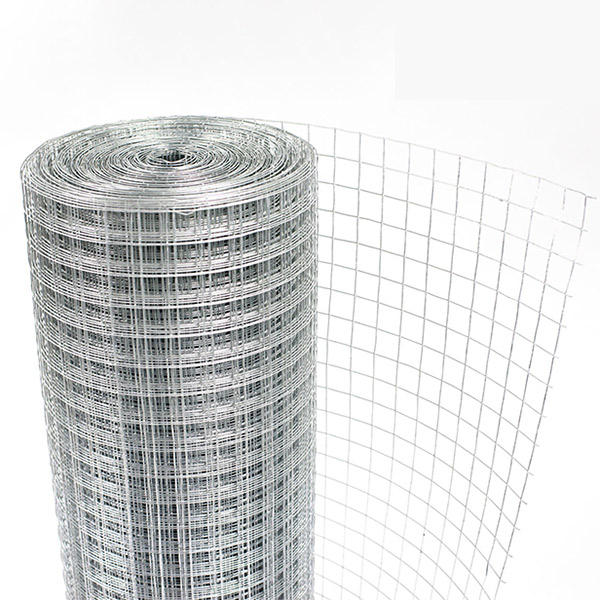

1. Construction In the construction industry, galvanized wire is utilized in building fences, wire mesh, and reinforcement for concrete structures. Its strength and weather-resistant properties make it an ideal choice for outdoor applications where durability is crucial.

2. Agriculture Farmers rely on galvanized wire for fencing livestock, creating trellises for plants, and supporting agricultural structures. The wire’s longevity against the elements ensures that it remains effective in protecting crops and animals over long periods.

3. Industrial Fabrication In industrial settings, galvanized wire is often used in manufacturing processes, including mesh making, wire forming, and crafting various products that require reliable strength and corrosion resistance.

The Role of Galvanized Wire Factories

galvanized wire factories

Galvanized wire factories are pivotal in supplying the demand across these diverse industries. Here are some critical aspects of their operations

1. Production Process The production of galvanized wire typically begins with drawing low-carbon steel wire through a series of dies to achieve the desired thickness. Following this, the wire undergoes cleaning to remove impurities, after which it is dipped in molten zinc for galvanization. This process is carefully controlled to ensure a uniform coating, vital for the wire’s performance.

2. Quality Control Leading galvanized wire manufacturers implement stringent quality control measures throughout the production process. From raw material selection to final inspections, these factories ensure that their products meet industry standards and customer specifications.

3. Innovation and Sustainability Many galvanized wire factories are incorporating innovative technologies to improve efficiency and reduce environmental impact. Modern processes may involve recycling zinc and optimizing energy use, demonstrating a commitment to sustainability. Furthermore, advancements in automated systems have streamlined production, enhancing output while maintaining product quality.

4. Global Reach With globalization, galvanized wire factories have expanded their markets, exporting products worldwide. This expansion has allowed industries in developing regions to benefit from high-quality galvanized wire, facilitating infrastructure development and agricultural growth.

Challenges and Future Trends

Despite the benefits, galvanized wire factories face challenges, including fluctuations in raw material prices and increased global competition. To remain competitive, manufacturers are focusing on research and development, exploring new materials and coatings that can further enhance the performance of galvanized wire.

Looking ahead, the demand for galvanized wire is expected to grow, driven by ongoing advancements in construction methods and agricultural practices. As industries evolve, galvanized wire factories will play a crucial role in meeting the needs of a changing market, demonstrating resilience and adaptability in the face of challenges.

Conclusion

In conclusion, galvanized wire factories are integral to the fabrication and supply of valuable materials that enhance the longevity and performance of various products across industries. Their commitment to quality, innovation, and sustainability ensures that they remain vital players in the modern industrial landscape. As the world continues to advance, the significance of galvanized wire and its manufacturing processes will undoubtedly persist, fostering resilience in multiple sectors of the economy.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025