Dec . 10, 2024 23:10 Back to list

Galvanized Wire Brick Reinforcement Mesh Supplier for Construction Applications

The Role of Galvanized Wire Brick Force Mesh in Construction

In the construction industry, materials play a crucial role in determining the structural integrity and durability of a project. One such material that has gained significant attention in recent years is the galvanized wire brick force mesh. This innovative product, manufactured from high-quality galvanized steel, offers numerous advantages for builders and contractors alike, making it a popular choice in modern construction practices.

Understanding Galvanized Wire Brick Force Mesh

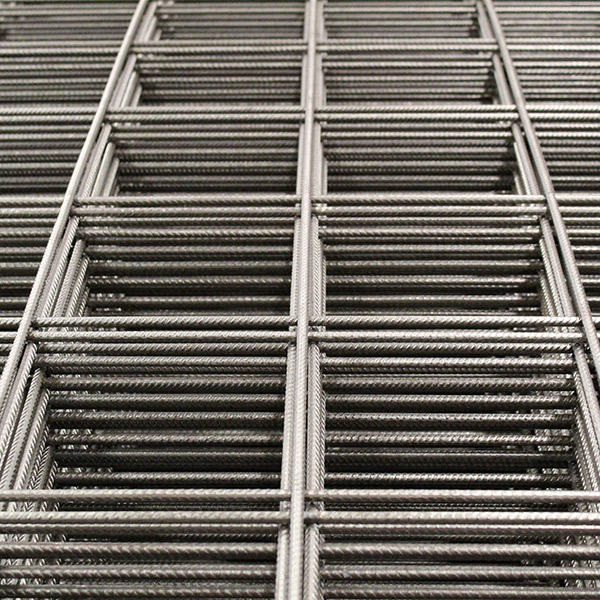

Galvanized wire brick force mesh is a type of reinforcement mesh made from galvanized steel wires designed specifically for use in bricklaying and masonry applications. The galvanization process involves coating the steel with a layer of zinc, protecting it from rust and deterioration over time, which is especially important in environments exposed to moisture and extreme weather conditions.

This mesh is typically composed of a grid-like structure, where horizontal and vertical wires intersect to form a robust framework. The size of the openings can vary depending on the specific requirements of the project, allowing for flexibility in design and application.

Key Benefits for Construction

1. Enhanced Strength and Durability One of the primary advantages of using galvanized wire brick force mesh is its ability to enhance the strength of building structures. When integrated into walls and foundations, the mesh provides additional tensile strength, ensuring that the brickwork can withstand various stresses, such as weight loads, environmental factors, and seismic activity.

2. Corrosion Resistance The galvanization process is essential for prolonging the life of steel in construction. As mentioned earlier, the zinc coating provides a protective barrier against moisture and other corrosive elements. This is particularly beneficial in regions with high humidity or where structures are exposed to direct contact with water, as it significantly reduces the risk of rusting and structural failure.

galvanized wire brick force mesh manufacturer

3. Cost-Effectiveness While the initial investment in galvanized wire mesh may be higher than traditional reinforcement methods, the long-term savings are substantial. The durability and reduced maintenance needs of galvanized wire mesh can lead to lower overall project costs, as fewer repairs and replacements are required over time.

4. Easy Installation The lightweight nature of galvanized wire mesh makes it easy to handle and install. Contractors can save on labor costs and time during the construction process. Additionally, its versatility allows for a range of applications, from residential buildings to larger commercial projects.

5. Versatile Applications Galvanized wire brick force mesh is not limited to a single type of construction. Its versatility means it can be used in a variety of settings, such as reinforcing brick walls, plastering applications, and even decorative features. This adaptability makes it a valuable material for architects and builders seeking innovative design solutions.

Choosing the Right Manufacturer

When selecting a galvanized wire brick force mesh manufacturer, it's essential to consider several factors, including the quality of materials, production methods, and reputations within the industry. A reliable manufacturer will adhere to strict quality control measures and ensure that their products meet relevant industry standards.

Furthermore, they should be able to provide guidance on the specific type of mesh suitable for individual projects, taking into account the unique requirements and conditions of each build.

Conclusion

In conclusion, galvanized wire brick force mesh represents a significant advancement in the construction industry. Its combination of strength, durability, and cost-effectiveness offers builders and contractors a reliable solution for reinforcing masonry structures. As construction projects continue to evolve, the demand for high-quality reinforcement materials like galvanized wire mesh is likely to grow, solidifying its position as an essential component in modern building practices. Embracing these innovations not only improves the safety and longevity of structures but also contributes to more efficient and sustainable construction methods.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025