Nov . 24, 2024 16:44 Back to list

galvanized wire brick force mesh manufacturer

Galvanized wire brick force mesh is an essential component in modern construction, widely recognized for its strength, durability, and versatility. Manufacturers of this mesh provide a critical solution for reinforcing masonry structures, enhancing their stability and longevity. This article explores the features, benefits, and manufacturing processes associated with galvanized wire brick force mesh while highlighting its importance in the construction industry.

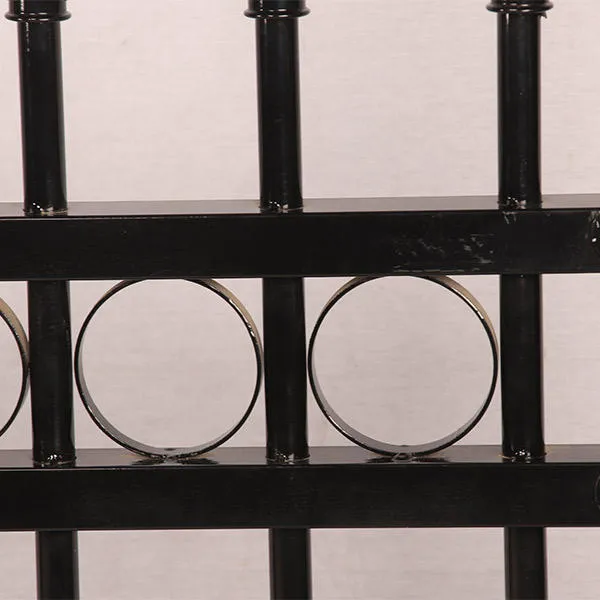

Galvanized wire brick force mesh is made from high-quality steel wire that has been coated with a layer of zinc to protect it from corrosion. The galvanization process not only extends the life of the wire but also ensures that it can withstand harsh environmental conditions, making it ideal for outdoor applications. This mesh is typically used to strengthen brick and block walls, providing structural support and preventing cracking and other forms of damage over time.

The manufacturing process of galvanized wire brick force mesh involves several stages. Initially, high-grade steel wire is drawn to the desired gauge, ensuring that it meets the necessary strength specifications. Following this, the wire undergoes a galvanization process, either through hot-dip galvanization or electro-galvanization, creating a protective zinc coating. After galvanization, the wire is woven into a mesh pattern, where the spacing and dimensions depend on the specific construction requirements. Quality control is paramount at this stage to ensure that the mesh meets industry standards and customer expectations.

One of the primary benefits of using galvanized wire brick force mesh is its ability to redistribute loads and stress throughout the structure. This is particularly crucial in regions prone to seismic activity or heavy winds. The mesh serves as a reinforcement framework, significantly enhancing the overall structural integrity of walls, ceilings, and floors. Additionally, the use of such mesh helps reduce the risk of moisture infiltration, as it provides a stable substrate for applying mortar, plaster, or other finishing materials.

galvanized wire brick force mesh manufacturer

Another advantage of galvanized wire brick force mesh is its cost-effectiveness. When compared to other reinforcement methods, such as rebar or fiber mesh, galvanized wire mesh often presents a more economical solution without compromising on quality or performance. This makes it an attractive option for both large-scale commercial projects and smaller residential constructions.

The versatility of galvanized wire brick force mesh extends beyond its use in masonry construction. It can also be applied in other areas such as fencing, agricultural applications, and even in the manufacturing of various products. As the construction industry continues to evolve, the demand for reliable and innovative reinforcement solutions like galvanized wire brick force mesh is expected to grow steadily.

In conclusion, galvanized wire brick force mesh represents a vital material in contemporary construction practices. Its robust design, corrosion resistance, and multifaceted applications make it a preferred choice for builders and manufacturers alike. As the industry pushes toward more durable and sustainable building methods, galvanized wire brick force mesh will undoubtedly continue to play a crucial role in shaping resilient structures for the future.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025