Nov . 10, 2024 07:43 Back to list

Manufacturers of 2mm Galvanized Wire for Various Applications and Industries

Exploring 2mm Galvanized Wire Factories A Key Component in Modern Industries

The demand for durable and corrosion-resistant materials has led to the widespread use of galvanized wire across various industries. Among these, 2mm galvanized wire has emerged as a popular choice due to its versatility and strength. Understanding the factories that produce this essential material can provide insight into its production process and applications.

What is Galvanized Wire?

Galvanized wire is steel wire that has been coated with a layer of zinc to protect it from rust and corrosion. This process, known as galvanization, typically involves either hot-dip or electro-galvanizing methods. The result is a strong, resilient wire capable of withstanding harsh environmental conditions. The 2mm thickness of the wire makes it suitable for a range of applications, from fencing to construction.

The Manufacturing Process

Factories that produce 2mm galvanized wire follow several steps in the manufacturing process. Initially, high-quality steel wire is drawn to the desired thickness. This drawing process involves pulling the steel through a series of dies, reducing its diameter while increasing its length. Achieving a uniform diameter and tensile strength is crucial for the wire’s performance.

Once the wire is drawn, the galvanization process begins. In hot-dip galvanization, the steel wire is submerged in molten zinc, forming a thick, protective coating. On the other hand, electro-galvanization uses an electric current to deposit a thin layer of zinc onto the wire. Each method has its advantages, with hot-dip providing a more robust coating suitable for outdoor applications.

Post-galvanization, the wires are cooled and inspected for quality

. Factories utilize advanced machinery to ensure that the wires are free of defects, properly coated, and meet industry standards. This stringent quality control ensures that the final product is durable and reliable.galvanized wire 2mm factories

Applications of 2mm Galvanized Wire

The versatility of 2mm galvanized wire allows it to be used in a variety of applications. One of the most common uses is in fencing and agriculture, where it provides a sturdy framework for enclosures that protect livestock and crops. Additionally, it is utilized in the construction industry for reinforcing concrete and as binding materials.

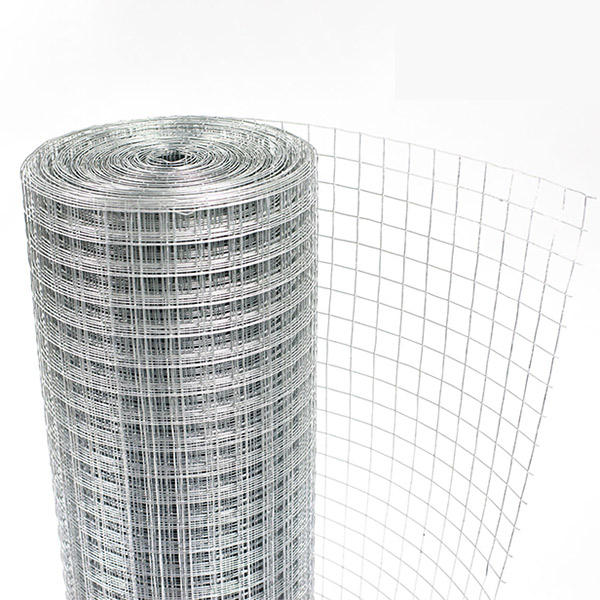

Moreover, 2mm galvanized wire is essential in the manufacturing of wire mesh, which is widely used in construction, agriculture, and landscaping. Its resilience against rust makes it ideal for outdoor use, ensuring longevity and reliability.

Choosing the Right Factory

When it comes to sourcing 2mm galvanized wire, it’s crucial to select a reputable factory. Factors to consider include the factory’s production capacity, quality assurance processes, and adherence to industry standards. Established factories often have certifications that showcase their commitment to quality and sustainability.

Additionally, it is beneficial to evaluate the factory’s technological capabilities. Advanced machinery and production techniques can enhance the quality of the galvanized wire and reduce production costs, ultimately benefiting the end-user.

Conclusion

In summary, 2mm galvanized wire is a vital material in numerous industries, thanks to its durability and resistance to corrosion. Factories that specialize in its production employ meticulous manufacturing processes to ensure that they meet the needs of their customers. As industries continue to evolve, the demand for high-quality galvanized wire will undoubtedly grow, strengthening its position as an essential component in modern applications. Understanding the production landscape of 2mm galvanized wire allows businesses to make informed choices when sourcing this critical material.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025