Dec . 10, 2024 20:53 Back to list

Galvanized Welded Mesh Production Facility Overview and Manufacturing Processes

The Importance of Galvanized Welded Mesh in Various Industries

In the modern industrial landscape, materials that offer durability, versatility, and resistance to corrosion are paramount. One such material that has gained significant traction is galvanized welded mesh. This article sheds light on the characteristics, applications, and benefits of galvanized welded mesh, highlighting its importance in construction, agriculture, and various other sectors.

What is Galvanized Welded Mesh?

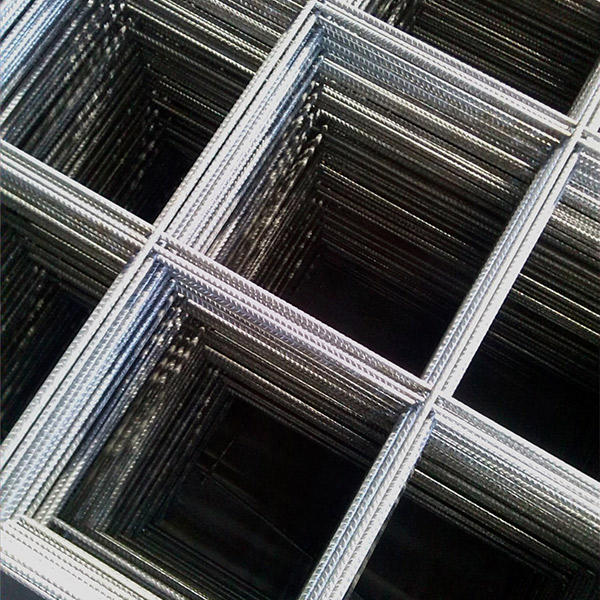

Galvanized welded mesh is a type of fencing and structural mesh made from steel wires that are welded together at intersections. After being welded, the mesh is subjected to a galvanizing process, where zinc is coated onto the steel surfaces. This coating provides exceptional protection against rust and corrosion, making galvanized welded mesh an ideal choice for outdoor and high-moisture environments.

Manufacturing Process

The manufacturing of galvanized welded mesh begins with high-quality steel wires, which are cut to the desired lengths. These wires are then arranged in a grid pattern before being welded at the intersections. After the welding process, the entire mesh is immersed in molten zinc, ensuring that every inch of the steel is coated. This galvanization process can either be done through hot-dip galvanizing or electro-galvanizing, with hot-dip being the more durable option. The result is a strong, stable, and corrosion-resistant mesh that can withstand various environmental conditions.

Applications of Galvanized Welded Mesh

1. Construction Galvanized welded mesh is widely used in the construction industry for reinforcing concrete. It provides added strength and durability to concrete structures, minimizing the risk of cracks and structural failure. It is commonly used in floors, walls, and slabs, as well as in precast concrete products.

2. Fencing One of the most popular applications of galvanized welded mesh is in fencing. Whether for residential, agricultural, or industrial purposes, galvanized welded mesh offers a secure barrier that is resistant to both weathering and physical damage. Its visibility ensures safety while maintaining an aesthetic appeal.

3. Agriculture In the agricultural sector, galvanized welded mesh is utilized for animal enclosures, poultry houses, and crop protection. Its strength prevents animals from escaping or intruding, while the mesh's design allows for adequate ventilation and light, promoting healthier environments for livestock and plants alike.

galvanized welded mesh factory

4. Architecture and Landscaping Architects and landscapers appreciate the versatility of galvanized welded mesh. It can be used for decorative fencing, retaining walls, and even as a support structure for climbing plants. The material's ability to withstand harsh weather conditions ensures that it retains its aesthetic appeal over time.

5. Industrial Applications In factories and warehouses, galvanized welded mesh can be employed for shelving systems, cages, and racks. Its ability to bear weight and resist corrosion makes it a practical choice for storage solutions.

Benefits of Galvanized Welded Mesh

1. Durability The primary benefit of galvanized welded mesh is its impressive durability. The galvanization process ensures that the mesh can withstand exposure to moisture, chemicals, and harsh weather conditions without deteriorating.

2. Low Maintenance Unlike untreated metals that require regular painting or coating, galvanized welded mesh requires minimal maintenance. Its long lifespan means fewer replacements and repairs, translating to cost savings for businesses and homeowners alike.

3. Versatility The adaptability of galvanized welded mesh allows it to be customized for various applications. It can be produced in different mesh sizes, wire diameters, and dimensions, accommodating the specific needs of each project.

4. Cost-Effective Considering its longevity and low maintenance requirements, galvanized welded mesh is a cost-effective material option. It provides a high return on investment, particularly in large-scale applications.

Conclusion

Galvanized welded mesh stands out as a reliable and efficient material, making it indispensable in a multitude of industries. With its unique combination of strength, corrosion resistance, and versatility, it addresses the diverse needs of construction, agriculture, fencing, and various industrial processes. As industries continue to evolve, the demand for materials like galvanized welded mesh is expected to grow, cementing its role as a staple in modern manufacturing and infrastructure development. Whether used for functional purposes or aesthetic enhancements, galvanized welded mesh is a testament to engineering excellence and practical design.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025