Dec . 03, 2024 14:02 Back to list

galvanized welded iron wire mesh manufacturers

Exploring the World of Galvanized Welded Iron Wire Mesh Manufacturers

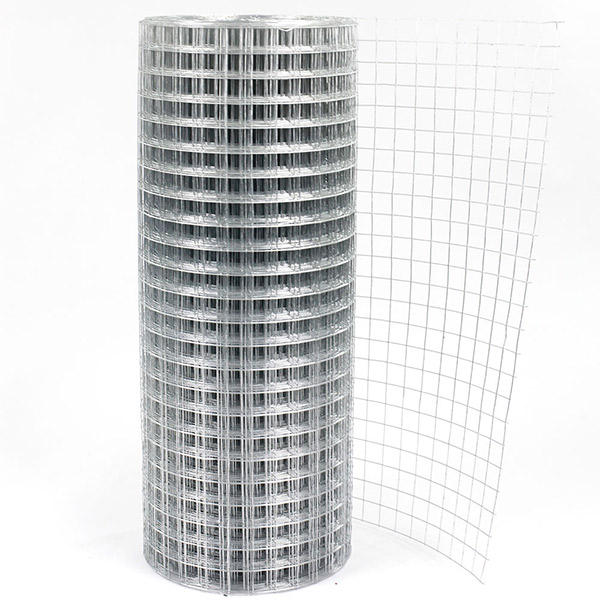

Galvanized welded iron wire mesh is a versatile and robust material used in various applications, ranging from construction to agriculture. It is preferred for its durability, resistance to corrosion, and structural integrity. When discussing manufacturers of galvanized welded iron wire mesh, it's essential to consider several factors, including production techniques, quality standards, and application-specific requirements.

What is Galvanized Welded Iron Wire Mesh?

Galvanized welded iron wire mesh is made by welding together iron wires, which are then coated with a layer of zinc to protect against rust and corrosion. The galvanization process can be done either through hot-dipping or electro-galvanizing. Hot-dipped galvanization involves immersing the welded mesh in molten zinc, providing a thick, long-lasting protective layer. In contrast, electro-galvanizing involves applying a thin layer of zinc through an electrochemical process. Both methods have their unique advantages and are chosen based on the specific requirements of the end application.

Key Applications

The applications for galvanized welded iron wire mesh are extensive

1. Construction Used for reinforcing concrete and masonry structures, providing strength and stability. It is commonly found in sidewalks, walls, and floors.

2. Fencing Ideal for agricultural fencing, garden fencing, and security barriers, galvanized welded wire mesh is effective in keeping livestock contained and securing properties.

3. Industrial Uses In industrial settings, it serves as guards for machines, safety barriers, and supports for bulk containers.

4. Agriculture Farmers utilize this mesh for cages, trellises, and plant supports, ensuring protection against pests and providing structural support.

galvanized welded iron wire mesh manufacturers

Choosing the Right Manufacturer

When selecting a manufacturer for galvanized welded iron wire mesh, a few critical considerations should guide your decision

1. Quality Standards Ensure that the manufacturer adheres to international quality standards. Look for certifications like ISO 9001, which indicates a commitment to quality management processes.

2. Production Capacity Assess the manufacturer’s production capacity to meet your project’s demands. A reliable supplier should have adequate resources and facilities to handle large-scale orders without compromising quality.

3. Customization Not all projects are the same, so manufacturers that offer customization in terms of size, wire diameter, and mesh design can better meet specific needs.

4. Market Reputation Research the manufacturer’s reputation in the industry. Customer reviews, testimonials, and case studies can provide insights into their reliability, product quality, and customer service.

5. Pricing While cost should not be the only determining factor, comparing prices among different manufacturers can help ensure you receive good value for your investment. However, it’s essential to balance quality against price.

6. Delivery and Support Efficient delivery schedules and after-sales support are crucial for maintaining project timelines. Manufacturers that provide timely delivery and are responsive to inquiries can significantly streamline your project workflow.

Conclusion

The landscape of galvanized welded iron wire mesh manufacturers is vast and diverse, catering to a wide range of applications and industries. By understanding the importance of quality, customization, and reputation, buyers can make informed decisions that ensure they select the best manufacturer for their needs. This material not only enhances structural integrity and safety but also represents a cost-effective solution for various fencing and construction applications.

As demand grows, innovative technologies and sustainable practices are likely to emerge within manufacturing processes. This evolution will further enhance the durability, functionality, and eco-friendliness of galvanized welded iron wire mesh, setting a new standard in the industry. Always remember that a well-chosen manufacturer not only contributes to the success of your project but also fosters a relationship that can lead to future collaborations.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025