Dec . 05, 2024 15:10 Back to list

galvanized trash rack steel grate manufacturer

Galvanized Trash Rack A Durable Solution for Effective Waste Management

In the ever-evolving industrial landscape, efficient waste management is a critical concern for companies looking to maintain environmental sustainability and adhere to regulations. One innovative solution that has gained prominence in recent years is the use of galvanized trash racks, particularly those made of steel. This piece delves into the significance of galvanized trash racks, their manufacturing process, and their benefits, making them an essential component in effective waste management systems.

Understanding Galvanized Trash Racks

Galvanized trash racks are designed to prevent debris and large materials from entering water intakes, drainage systems, or other critical infrastructure. Typically made from steel and coated with a layer of zinc, these structures are not only robust but also resistant to corrosion, making them ideal for outdoor settings exposed to harsh weather conditions. Their primary function is to filter out unwanted waste, ensuring that only clean water passes through, thus safeguarding associated equipment and systems from damage.

The Manufacturing Process

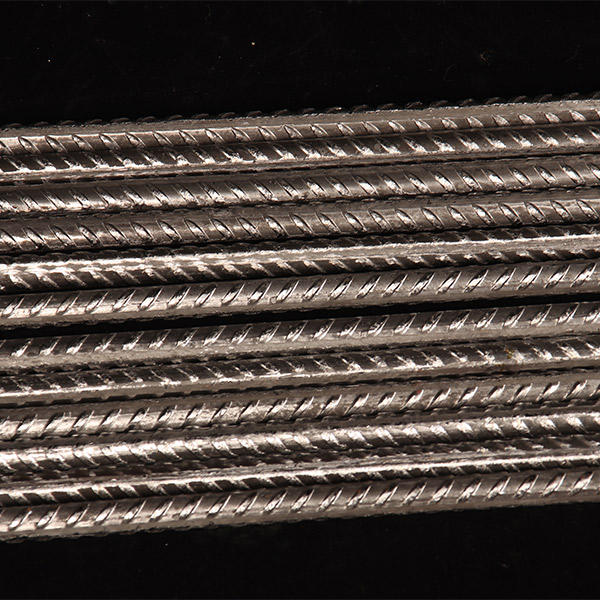

The production of galvanized trash racks starts with selecting high-quality steel, which forms the backbone of these structures. Manufacturers utilize advanced fabrication techniques to cut and shape the steel into the required grid patterns. Once the rack has been shaped, it undergoes a galvanization process, where it is submerged in molten zinc. This process not only provides a protective layer to the steel, enhancing its durability and lifespan, but also improves its resistance to rusting and other environmental factors.

Advanced manufacturers take great care in ensuring quality at every stage, from the sourcing of materials to the final inspection before delivery. Many manufacturers also offer customization options, allowing industries to request specific sizes, designs, and load-bearing capacities tailored to their unique requirements.

Key Benefits of Galvanized Steel Grates

1. Durability One of the most significant advantages of galvanized trash racks is their durability. The galvanization process creates a robust barrier against environmental wear and tear, extending the life of the racks and minimizing the need for regular replacements.

galvanized trash rack steel grate manufacturer

2. Corrosion Resistance The zinc coating significantly enhances the corrosion resistance of the steel, making galvanized trash racks suitable for a variety of applications, including coastal areas where salty air could lead to rapid deterioration.

3. Low Maintenance Given their resilient nature, these racks require minimal maintenance. Periodic inspections and minor clean-ups can often suffice to keep them functioning effectively, allowing facilities to focus their resources elsewhere.

4. Cost-Effective Although the initial investment may be higher compared to non-galvanized options, the long lifespan and reduced maintenance needs of galvanized trash racks often translate to greater cost savings over time.

5. Environmental Impact By keeping waterways clear of debris and pollutants, galvanized trash racks play a critical role in maintaining environmental integrity. Their use contributes to cleaner water resources, promoting healthier ecosystems.

Applications Across Industries

Galvanized trash racks find applications in various sectors, including municipal water treatment facilities, stormwater management systems, power plants, and irrigation systems. Their versatility allows them to be used in both large-scale industrial settings and localized municipal projects.

Conclusion

As industries continue to address growing environmental challenges, the demand for effective waste management solutions, such as galvanized trash racks, will undoubtedly increase. Their ability to combine durability, low maintenance, and environmental protection makes them a preferred choice for manufacturers and facility operators alike. By investing in high-quality galvanized steel grates, industries not only comply with regulatory requirements but also contribute positively to the health of our planet. As the market for these products evolves, forward-thinking companies will continue to prioritize sustainable practices, setting a benchmark for others to follow.

-

Hot Dipped Galvanized Steel Grating Durable & Corrosion-Resistant Solutions

NewsMay.31,2025

-

Plastic-Coated Hexagonal Wire Mesh Manufacturer Durable Solutions

NewsMay.31,2025

-

Reinforced Concrete Expanded Metal Mesh Suppliers & Factories High-Strength

NewsMay.31,2025

-

Galvanized Steel Wire High-Strength, Rustproof Material & Suppliers

NewsMay.30,2025

-

1 Inch Hexagonal Wire Mesh Heavy-Duty Factories & Suppliers

NewsMay.30,2025

-

Green PVC Coated Wire Durable, Weather-Resistant Electrical Solutions

NewsMay.30,2025