Nov . 12, 2024 19:55 Back to list

galvanized steel wire factory

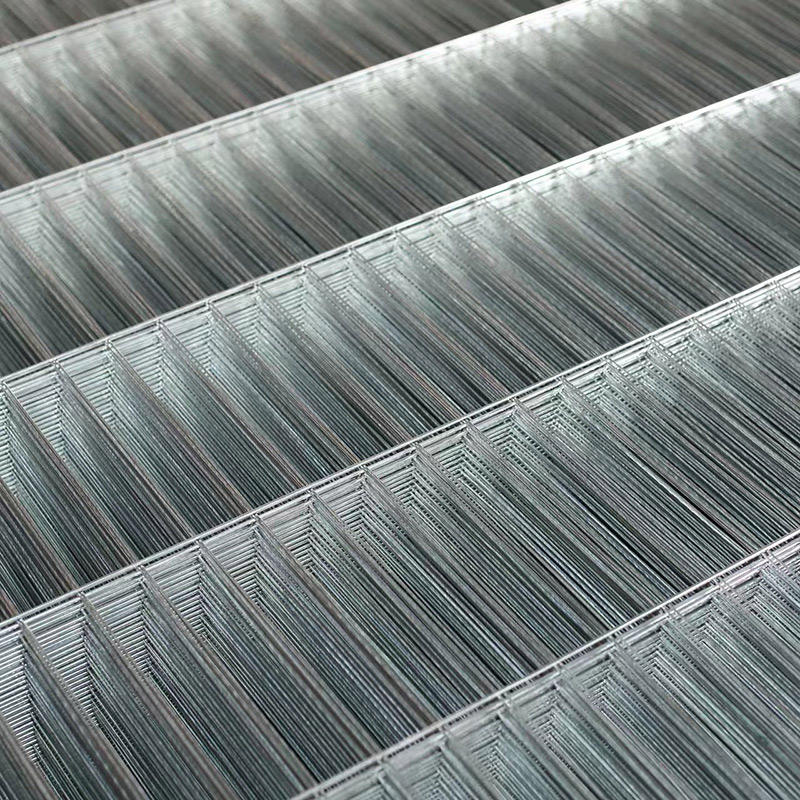

The Importance and Process of Galvanized Steel Wire Production

Galvanized steel wire has become an indispensable material in various industries due to its exceptional durability, resistance to corrosion, and versatility. The production of galvanized steel wire involves a meticulous process that combines advanced technologies with age-old techniques, ensuring that the final product meets the highest standards of quality and performance.

Understanding Galvanization

Before delving into the production process, it’s essential to understand what galvanization is. Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rusting. This is crucial because, when exposed to environmental elements, unprotected steel can corrode and deteriorate rapidly. By using galvanized steel, industry professionals can extend the lifespan of products, structures, and tools significantly.

Raw Material Selection

The first step in producing galvanized steel wire is selecting the right raw materials, typically high-quality steel wire rods. The choice of steel is essential as it influences the mechanical properties of the final product. Factories often source their steel from reputable suppliers to ensure consistency and reliability. The selected steel is then drawn through a series of dies to achieve the desired wire diameter. This wire drawing process can produce various thicknesses, catering to different applications, from fencing to construction.

Cleaning and Annealing

Once the wire is drawn to the required size, it undergoes a thorough cleaning process. This step is crucial as any contaminants on the wire’s surface can lead to poor adhesion of the zinc coating. The cleaning process generally involves a combination of mechanical and chemical methods to remove oil, dirt, and oxides. After cleaning, the wire is often subjected to annealing, which involves heating it in a controlled environment. Annealing helps to improve the ductility and strength of the steel wire, making it easier to work with during the galvanization phase.

The Galvanization Process

galvanized steel wire factory

The heart of the galvanized steel wire production lies in the galvanization process itself. There are primarily two methods for galvanizing steel wire hot-dip galvanizing and electro-galvanizing.

1. Hot-Dip Galvanizing In this method, the cleaned and annealed wire is dipped into a molten zinc bath. The wire surface reacts with the zinc, forming a robust alloyed coating that provides excellent corrosion resistance. This process is favored for its durability and is typically used for wires that will be exposed to harsh environmental conditions, such as those used in agricultural fencing and utility applications.

2. Electro-Galvanizing This alternative method involves depositing a zinc layer on the wire via an electrochemical process. While the coating from electro-galvanizing may be thinner than that from hot-dip galvanizing, it offers a smooth finish and is often used for wires requiring a more aesthetic appearance, such as those used in automotive applications.

Quality Control and Testing

After galvanization, galvanized steel wire undergoes rigorous quality control to ensure that it meets industry standards. Several tests may be conducted, including tensile strength tests, ductility tests, and corrosion resistance tests. Manufacturers understand that maintaining high-quality standards is essential, as defective products can lead to significant financial losses and safety hazards.

Applications of Galvanized Steel Wire

Galvanized steel wire finds applications in a myriad of industries. It is widely used in construction for reinforcing concrete, in agriculture for fencing and trellising, and in manufacturing for producing various wire products. Its versatility makes it a favored choice for both industrial and domestic applications.

Conclusion

The production of galvanized steel wire is a sophisticated blend of science and craftsmanship, underscoring the importance of quality and innovation in manufacturing. As industries continue to seek materials that offer longevity and reliability, galvanized steel wire will remain at the forefront, driving progress in construction, agriculture, and beyond. Its role in enhancing the durability of structures and products ensures that galvanized steel wire is not merely a material but a vital component in building a sustainable future.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025