Dec . 07, 2024 12:31 Back to list

galvanized reinforced concrete net manufacturers

The Rise of Galvanized Reinforced Concrete Net Manufacturers An Overview

In recent years, the construction industry has witnessed a significant shift towards the use of advanced materials that enhance durability, sustainability, and safety. Among these innovations, galvanized reinforced concrete nets have emerged as a pivotal component in modern construction practices. These nets provide crucial support and reinforcement to various structures, from residential buildings to large-scale infrastructure projects. As a result, the market for galvanized reinforced concrete net manufacturers is thriving, driven by an increasing demand for high-quality construction materials.

Understanding Galvanized Reinforced Concrete Nets

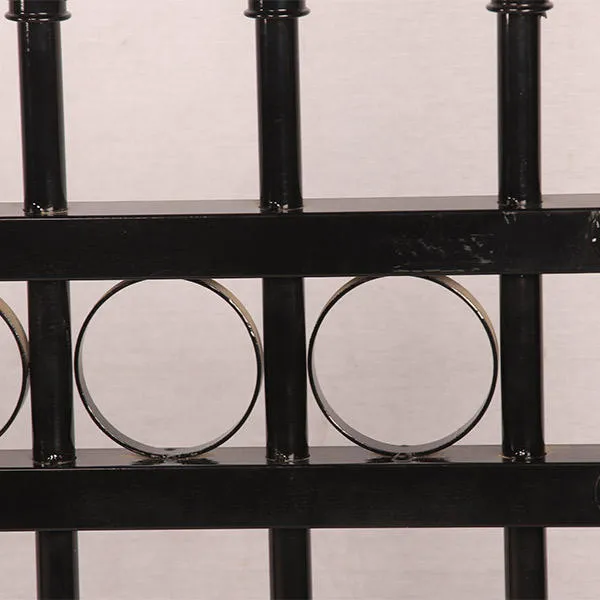

Galvanized reinforced concrete nets are made by embedding steel wires within a concrete matrix, which is then treated with a protective galvanization process. This process involves coating the steel with a layer of zinc, which provides excellent corrosion resistance and makes the material suitable for various environmental conditions. The use of these nets not only enhances the structural integrity of concrete but also extends the lifespan of construction projects by mitigating the effects of rust and deterioration.

These nets come in various sizes and configurations, allowing manufacturers to tailor their products to meet specific project requirements. The versatility of galvanized reinforced concrete nets is one of the reasons they have gained popularity across different sectors, including residential, commercial, and infrastructural development.

The Market Landscape

The growth of the construction industry, particularly in emerging economies, has further fueled the demand for galvanized reinforced concrete nets. As urbanization continues to accelerate, so does the need for reliable building materials that can withstand the rigors of modern life. Galvanized reinforced concrete nets offer a perfect solution, providing strength and stability to structures while ensuring cost-effectiveness.

Manufacturers in this space are increasingly adopting advanced technologies to produce higher-quality products that meet international standards. Innovations in manufacturing processes, such as automated production lines and quality control measures, ensure that the nets are uniform in quality and performance. Additionally, the integration of environmentally friendly practices, including the use of recycled materials and sustainable production methods, is becoming increasingly common among manufacturers, appealing to a growing market of eco-conscious consumers.

galvanized reinforced concrete net manufacturers

Challenges Faced by Manufacturers

Despite the promising market outlook, galvanized reinforced concrete net manufacturers face several challenges. The construction industry is often subject to fluctuations in demand due to economic conditions, which can impact production levels. Additionally, sourcing high-quality raw materials at competitive prices presents a continual challenge, especially in regions where steel prices are volatile.

Moreover, competition in the market is intensifying as new entrants emerge, offering alternative solutions and innovative materials. To maintain a competitive edge, existing manufacturers must continually invest in research and development, striving to improve product quality and reduce production costs.

Future Prospects

Looking ahead, the future of galvanized reinforced concrete net manufacturers appears bright. The growing emphasis on infrastructure development, particularly in developing nations, and the increasing awareness of the importance of sustainable construction materials are likely to sustain demand for these products. Additionally, as industries such as renewable energy and transportation expand, the need for robust and reliable construction materials will only grow.

Manufacturers that can adapt to market trends and invest in innovation will likely benefit from the rising demand. Collaboration with construction firms, architects, and engineers also presents opportunities for manufacturers to create tailored solutions that meet specific project needs, thereby enhancing their market position.

In conclusion, galvanized reinforced concrete nets are becoming an indispensable component in contemporary construction, driven by their durability, safety, and versatility. As the market continues to evolve, manufacturers who embrace innovation and sustainability will play a crucial role in shaping the future of the construction industry. With the ongoing trends in urbanization and infrastructure development, the demand for galvanized reinforced concrete nets is set to grow, marking a promising horizon for manufacturers in this field.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025