Dec . 11, 2024 18:00 Back to list

Galvanized Metal Wire Suppliers for Construction and Industrial Use

The Importance of Galvanized Metal Wire in Construction A Reliable Supplier's Perspective

In the world of construction, the choice of materials can significantly impact the quality, durability, and longevity of a project. One such material that has gained popularity for its various beneficial properties is galvanized metal wire. This article aims to explore the importance of galvanized metal wire in construction and the advantages of working with a reliable supplier.

Understanding Galvanized Metal Wire

Galvanized metal wire is produced by coating iron or steel wire with a layer of zinc. This process, known as galvanization, protects the wire from corrosion and rust, making it suitable for a wide range of applications, especially in construction. The benefits of galvanized wire stem from its durability and resistance to harsh environmental conditions, which is essential in construction projects exposed to elements.

Applications in Construction

Galvanized metal wire finds multiple uses in the construction industry. From reinforcement to fencing, its versatility is unmatched. Here are some common applications

1. Reinforcement Galvanized wire is often used in concrete reinforcement. It helps provide additional strength and stability to structures, ensuring they can withstand stress and loads over time.

2. Fencing The durability of galvanized wire makes it an ideal choice for fencing applications. Whether for securing construction sites or demarking boundaries, the wire's resistance to rust ensures that it withstands weathering, maintaining its integrity over the years.

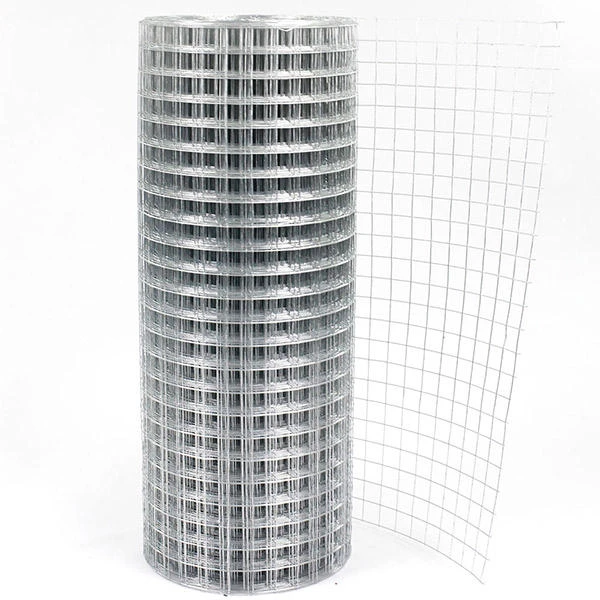

3. Mesh for Concrete In the form of welded wire mesh, galvanized metal wire is used in concrete slabs and walls, providing vital reinforcement that enhances the structural integrity of buildings.

4. Hanging and Supporting Various systems, such as suspended ceilings and light fixtures, often utilize galvanized wire for hanging and support due to its strength and flexibility.

5. Binding and Tying In construction, it is common to use galvanized wire for tying rebar or lattice forms, as its tensile strength ensures reliable binding without fear of corrosion.

Benefits of Using Galvanized Metal Wire

The advantages of using galvanized metal wire in construction are numerous

galvanized metal wire for construction supplier

- Corrosion Resistance The zinc coating acts as a barrier against moisture and chemicals, thus preventing rust and extending the lifespan of the wire.

- Cost-Effectiveness While galvanized steel might have a higher upfront cost compared to untreated steel, its durability and long lifespan save money in the long run.

- Maintenance-Free Unlike other materials, galvanized wire requires minimal maintenance, making it an ideal choice for projects where upkeep is challenging.

- Eco-Friendly Zinc is a recyclable material, and the process of galvanization is efficient, making it a more environmentally friendly option compared to other protective coatings.

Choosing a Reliable Supplier

To fully harness the benefits of galvanized metal wire, it is crucial to select a reliable supplier. Here are some factors to consider when making your choice

1. Quality Assurance Ensure that the supplier maintains high standards in their production process. Look for products that meet industry standards and certifications.

2. Experience and Reputation A supplier with a proven track record in the construction industry will likely provide better service and product quality. Look for testimonials and reviews from previous clients.

3. Range of Products A good supplier should offer a variety of galvanized wire products to meet diverse construction needs.

4. Customer Support Select a supplier that provides excellent customer service, as this can assist in addressing any queries or issues that may arise.

5. Competitive Pricing While price should not be the sole factor, finding a supplier that offers competitive pricing without compromising on quality is essential.

Conclusion

Galvanized metal wire plays a pivotal role in construction by providing durability, strength, and resistance to environmental damage. Choosing the right supplier can enhance the overall success of construction projects. With reliable galvanized metal wire, construction professionals can build structures that not only stand the test of time but also deliver safety and performance. Investing in high-quality materials is key to achieving lasting results in the rapidly evolving construction landscape.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025