Dec . 05, 2024 20:55 Back to list

Galvanized Wire Solutions for Construction Factories and Industrial Applications

The Importance of Galvanized Metal Wire in Construction

In the realm of construction, durability and resilience are paramount. One material that has become increasingly important in this field is galvanized metal wire. This article explores the properties, applications, and advantages of galvanized metal wire in construction, showcasing why it has become a favored choice for contractors and builders around the world.

What is Galvanized Metal Wire?

Galvanized metal wire is made from steel or iron that has been coated with a layer of zinc. This process, known as galvanization, provides a protective barrier against corrosion and rust, significantly extending the wire's lifespan. The zinc coating not only enhances the aesthetic appeal of the wire but also makes it suitable for various environmental conditions, making it an ideal choice for construction applications.

Properties of Galvanized Metal Wire

1. Corrosion Resistance The primary advantage of galvanized metal wire is its resistance to corrosion. In construction, materials are often exposed to moisture, extreme temperatures, and various weather conditions. Galvanized wire can withstand these elements, ensuring it maintains its integrity over time.

2. Strength and Durability Galvanized wire possesses a high tensile strength, making it robust enough to be used in demanding applications. Its durability ensures that it can support heavy loads without deforming, a crucial factor in construction projects.

3. Flexibility Despite being robust, galvanized wire is also incredibly flexible, allowing it to be shaped and manipulated easily. This quality enables builders to use it in various configurations, from creating reinforced structures to intricate designs.

4. Cost-Effectiveness While galvanized metal wire may have a higher initial cost than non-galvanized alternatives, its long lifespan and low maintenance requirements make it more cost-effective in the long run.

Applications in Construction

Galvanized metal wire has a multitude of applications in construction, including

1. Reinforcement It is often used to reinforce concrete and masonry structures, providing additional strength and support. This is especially important in areas prone to seismic activity or heavy loads.

galvanized metal wire for construction factory

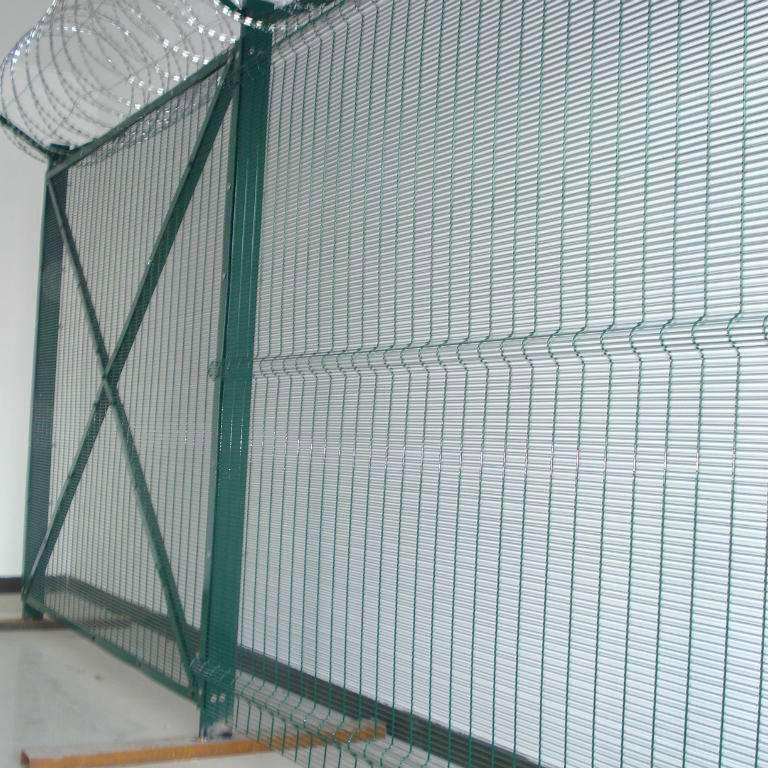

2. Fencing The strength and corrosion resistance of galvanized wire make it ideal for fencing applications. It is used in agricultural settings, residential areas, and industrial sites to create secure boundaries.

3. Electrical Wiring Galvanized wire is widely used in the electrical industry for grounding and other applications due to its conductive properties and resistance to rust.

4. Concrete Mesh Galvanized wire is crafted into mesh forms that are used in concrete slabs, walls, and other structures to prevent cracking and provide stability.

5. Crafting and DIY Projects Apart from commercial construction, galvanized wire is popular for crafting and DIY projects due to its versatility and ease of use.

Advantages Over Other Materials

Compared to other materials, galvanized metal wire stands out due to its unique combination of properties. For instance, while stainless steel offers excellent corrosion resistance, it is often more expensive. On the other hand, non-galvanized wire can be prone to rusting, especially in outdoor settings.

Additionally, galvanized wire is compatible with various construction methods, making it a versatile choice for builders. It can be easily welded, tied, or connected to other materials, allowing for flexibility in construction techniques.

Environmental Considerations

As sustainability becomes increasingly important in today’s construction industry, galvanized metal wire offers several eco-friendly benefits. The process of galvanization is less harmful compared to other forms of metal treatment, and its longevity means lower material turnover and waste. As galvanized wire is fully recyclable, it contributes to a circular economy, aligning with modern construction's sustainability goals.

Conclusion

Galvanized metal wire is an indispensable material in the construction industry. Its corrosion resistance, strength, flexibility, and cost-effectiveness make it a top choice for a wide range of applications, from reinforcement to fencing and beyond. As builders continue to seek durable solutions for their projects, galvanized wire will undoubtedly remain a staple in construction, contributing to the safety and longevity of structures worldwide. Emphasizing quality and resilience, galvanized metal wire serves as a testament to modern engineering and construction practices.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025