Nov . 17, 2024 19:43 Back to list

galvanized iron wire for fencing manufacturers

The Rise of Galvanized Iron Wire for Fencing A Manufacturer's Perspective

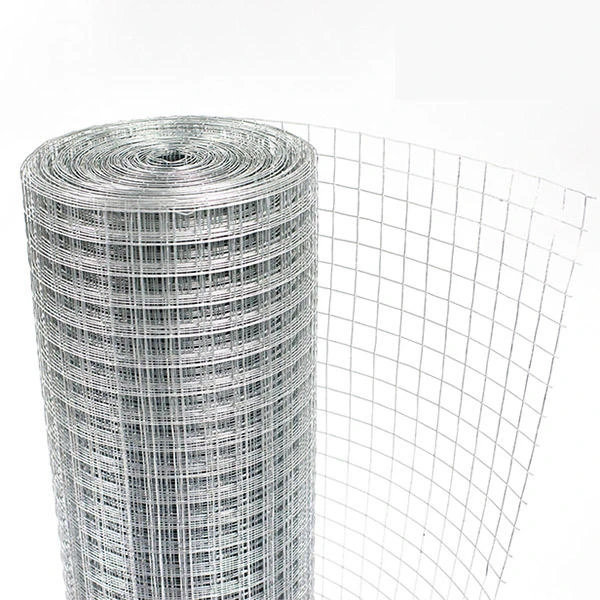

In today's rapidly evolving industrial landscape, fencing solutions have become an essential aspect of various applications, ranging from agricultural and residential to commercial and industrial uses. Among the various materials available, galvanized iron wire has emerged as a preferred choice for fencing manufacturers worldwide. This article delves into the properties, benefits, and relevance of galvanized iron wire in the fencing industry.

Understanding Galvanized Iron Wire

Galvanized iron wire is produced by coating steel or iron wire with a layer of zinc through a process known as galvanization. This protective layer not only enhances the wire's durability but also provides it with superior corrosion resistance. The galvanization process can be achieved through hot-dip galvanizing or electro-galvanizing, both of which ensure that the wire is shielded from the harsh elements of nature, such as rain, humidity, and exposure to chemicals.

Benefits of Galvanized Iron Wire

1. Durability and Longevity One of the primary advantages of galvanized iron wire is its exceptional durability. The zinc coating protects the underlying metal from corrosion, significantly extending the lifespan of the fencing material. Manufacturers report that properly galvanized wire can last for decades, making it a cost-effective option in the long run.

2. Low Maintenance Unlike untreated wire that requires regular maintenance to prevent rusting and weakening, galvanized iron wire necessitates minimal upkeep. This factor is particularly appealing to consumers looking for low-maintenance solutions, allowing them to focus on other aspects of their endeavors without worrying about the integrity of their fencing.

3. Versatility Galvanized iron wire is incredibly versatile and can be used in a wide range of applications. Whether for securing livestock in agricultural settings, protecting properties, or creating barriers for industrial sites, the adaptability of this material makes it a go-to choice for manufacturers.

galvanized iron wire for fencing manufacturers

4. Cost-Effectiveness While the initial investment for galvanized iron wire might be slightly higher than that of non-galvanized alternatives, the long-term savings in maintenance costs and replacement expenses make it a financially savvy choice. Manufacturers can provide competitive pricing to customers looking for value without compromising on quality.

5. Environmentally Friendly Zinc, the primary component of the galvanization process, is a natural element that poses no significant environmental threat. Additionally, the long life expectancy of galvanized iron wire reduces the need for frequent replacements, thus contributing to a lower environmental footprint.

The Role of Manufacturers

As demand for galvanized iron wire for fencing continues to grow, manufacturers play a crucial role in ensuring that the quality of the product meets industry standards. This involves adopting modern techniques in the galvanization process, investing in quality control measures, and synthesizing customer feedback to enhance product offerings.

Manufacturers also need to ensure that they maintain a sustainable supply chain, continually sourcing high-quality raw materials and adopting eco-friendly practices in their operations. Engaging with customers, understanding their specific needs, and providing tailored solutions will enhance their market position.

Conclusion

Galvanized iron wire has firmly established itself as a reliable choice for fencing solutions. Its remarkable durability, low maintenance needs, versatility, and cost-effectiveness resonate well with manufacturers and consumers alike. As the fencing industry evolves, galvanized iron wire will likely continue to dominate, thanks to its myriad benefits and the ongoing innovations by manufacturers. Embracing this material not only ensures robust security and boundary demarcation but also represents a step towards sustainable and long-lasting solutions in fencing applications.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025