Nov . 09, 2024 14:31 Back to list

Manufacturers of Galvanized Brick Coil Wire Mesh for Masonry Applications

Understanding Galvanized Brick Coil Wire Mesh for Masonry A Guide to Manufacturers

In the realm of construction and architecture, the materials used can significantly influence the integrity and durability of structures. One such material that has gained prominence in recent years is galvanized brick coil wire mesh. This versatile product serves as a reinforcement element in masonry, providing enhanced stability and longevity to brick structures. As the demand for such materials increases, numerous manufacturers have emerged, each vying to offer superior products. This article delves into the characteristics and benefits of galvanized brick coil wire mesh, as well as the role of manufacturers in this industry.

What is Galvanized Brick Coil Wire Mesh?

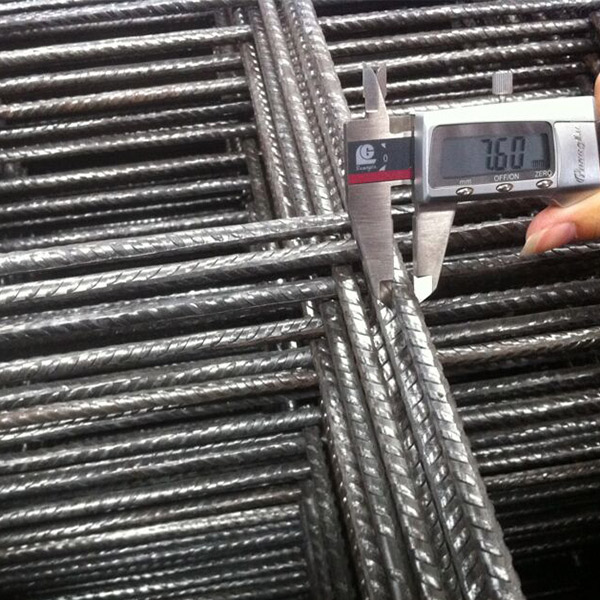

Galvanized brick coil wire mesh is a type of mesh that is made from wire that has been coated with a layer of zinc. This galvanization process protects the wire from corrosion and rust, making it ideal for use in masonry applications. The term coil refers to the way the wire mesh is manufactured and stored, allowing for easy handling and deployment at construction sites.

Masonry, which includes materials such as brick, stone, and concrete, is inherently sturdy but can benefit from additional reinforcement. Galvanized brick coil wire mesh is typically used as a grid that can be embedded within walls or facades, offering structural support and enhancing the overall strength of the masonry.

Benefits of Galvanized Brick Coil Wire Mesh

1. Corrosion Resistance The galvanization of the wire mesh ensures that it is protected against moisture and environmental elements, thereby extending the lifespan of the material. This quality is particularly essential in regions with high humidity or rainfall.

2. Enhanced Strength When incorporated into masonry, galvanized brick coil wire mesh provides additional tensile strength. This reinforcement minimizes the risk of cracks and structural failures, making buildings more resilient to stress and shifting conditions.

3. Lightweight Design Compared to traditional masonry reinforcement methods, the use of wire mesh offers a lightweight alternative that does not significantly add to the overall weight of the structure. This quality facilitates easier transportation and installation.

4. Flexibility in Design The mesh can be custom-made to fit various architectural designs and can be adapted to meet specific engineering needs, allowing architects and builders more flexibility in their creations.

galvanized brick coil wire mesh masonry manufacturers

5. Cost-effectiveness By increasing the durability and lifespan of brick structures, galvanized wire mesh can prove to be a cost-effective solution in the long run. It reduces maintenance costs and the likelihood of repairs caused by structural weaknesses.

Role of Manufacturers

As the demand for galvanized brick coil wire mesh grows, so does the competition among manufacturers. They play a critical role in ensuring that high-quality materials are available to builders and contractors. Here are some ways manufacturers can make a difference

1. Quality Control Reputable manufacturers implement stringent quality control processes to produce wire mesh that meets industry standards. This ensures the safety and reliability of their products.

2. Innovation With technological advancements, manufacturers are constantly evolving their production methods to improve the quality and performance of galvanized wire mesh. Innovative approaches may include developing new coatings or production techniques that enhance durability.

3. Sustainability Efforts Many manufacturers are becoming increasingly aware of their environmental impact. Some are investing in sustainable practices, such as using recycled materials or optimizing energy consumption during production.

4. Custom Solutions Leading manufacturers often offer customization options to meet specific project requirements. This capability can be essential for large-scale construction projects that require tailored solutions.

5. Customer Support A good manufacturer will provide effective customer service, assisting builders and contractors with guidance on product specifications, installation practices, and after-sales support.

Conclusion

Galvanized brick coil wire mesh has emerged as an essential component in modern masonry construction, delivering numerous benefits such as corrosion resistance, enhanced strength, and flexibility in design. As a result, the role of manufacturers becomes increasingly significant in ensuring that high-quality products are available to the industry. By understanding the characteristics and advantages of this material, builders and architects can make informed decisions that contribute to the durability and longevity of their structures. As the construction industry continues to evolve, galvanized wire mesh will undoubtedly play a crucial role in shaping the future of masonry.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025