Nov . 23, 2024 20:30 Back to list

galvanized brick coil wire mesh masonry factories

The Essential Role of Galvanized Brick Coil Wire Mesh in Masonry Factories

In the construction industry, the importance of durable materials cannot be overstated. One such material that has gained prominence in masonry applications is the galvanized brick coil wire mesh. This innovative solution provides structural integrity, enhances durability, and ensures the longevity of masonry constructions. In this article, we will explore the properties, benefits, and applications of galvanized brick coil wire mesh within masonry factories.

Galvanized wire mesh is created by coating steel wire with a layer of zinc. This process, known as galvanization, protects the wire from corrosion and rust, significantly extending its lifespan. The use of galvanized brick coil wire mesh in masonry enables builders to create resilient brick structures that can withstand the test of time and environmental challenges. The coating also provides aesthetic advantages, allowing for cleaner lines and a more polished finish.

One of the key benefits of using galvanized wire mesh in masonry is its strength and support. The mesh acts as a reinforcement system, providing additional stability to brickwork. This reinforcement is crucial in areas subjected to heavy loads or seismic activity. When integrated into the masonry structure, the galvanized wire mesh helps distribute weight uniformly, minimizing the risk of cracks and structural failure.

In masonry factories, the efficient application of galvanized brick coil wire mesh is a game changer. The wire mesh can be easily cut, shaped, and installed, making it a versatile choice for construction projects. It can be used in various masonry types, including walls, ceilings, and floors. Moreover, the lightweight nature of the mesh allows for easier handling and installation, saving time and labor costs in the construction process.

galvanized brick coil wire mesh masonry factories

Another notable advantage of galvanized wire mesh is its resistance to weather conditions. Whether exposed to extreme temperatures, moisture, or heavy winds, galvanized wire mesh maintains its integrity and does not compromise the structural strength of the masonry. This characteristic is particularly important in regions with harsh climates, as it ensures that the masonry work remains intact and functional over the years.

In addition to its functional benefits, the use of galvanized brick coil wire mesh in masonry contributes to sustainable building practices. By extending the lifespan of masonry structures and reducing the need for frequent repairs or replacements, galvanized wire mesh aligns with sustainability goals in the construction industry. Its longevity results in less material waste and lower resource consumption over time.

Furthermore, the application of galvanized wire mesh aids in compliance with building codes and regulations. As safety standards become increasingly stringent, the incorporation of strong reinforcement systems like galvanized wire mesh ensures that masonry constructions meet the necessary structural requirements, providing peace of mind to builders and property owners alike.

In conclusion, galvanized brick coil wire mesh represents a vital advancement in masonry construction. Its strength, durability, and versatility make it an essential material in modern masonry factories. By enhancing the structural integrity of brickwork, providing resistance against environmental challenges, and supporting sustainable construction practices, galvanized wire mesh is undeniably a cornerstone in the creation of resilient and long-lasting masonry structures. As the construction industry continues to evolve, incorporating innovative materials like galvanized brick coil wire mesh will remain essential for achieving high-quality outcomes in masonry projects.

-

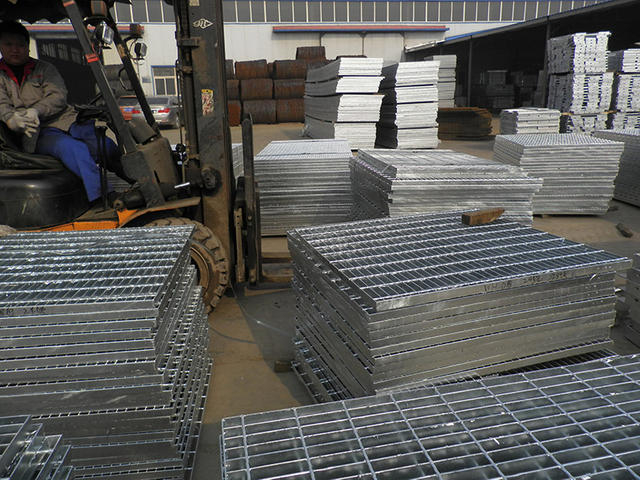

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025