Nov . 12, 2024 08:59 Back to list

galvanized binding wire manufacturers

The Evolution and Importance of Galvanized Binding Wire A Comprehensive Look at Manufacturers

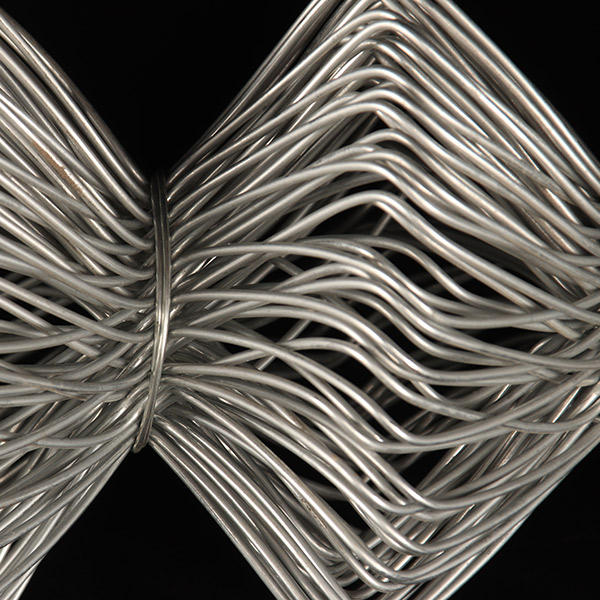

In the realm of construction and manufacturing, the importance of durable and reliable materials cannot be overstated. One such crucial material is galvanized binding wire. This versatile product plays a significant role in various applications, particularly in reinforcing structures, bundling materials, and securing components together. Understanding the significance of galvanized binding wire manufacturers can provide valuable insights into the industry and the essential functions these products serve.

What is Galvanized Binding Wire?

Galvanized binding wire is steel wire that has been coated with a layer of zinc to enhance its corrosion resistance. This process, known as galvanization, ensures that the wire can withstand harsh environmental conditions, making it ideal for both indoor and outdoor use. Galvanized binding wire typically comes in various gauges and strengths, making it suitable for a wide range of applications, from construction to agriculture.

The Manufacturing Process

The manufacturing of galvanized binding wire involves several crucial steps. First, high-quality steel wire is drawn to the desired gauge. The wire is then cleaned to remove any impurities and is subsequently galvanzied through either hot-dip or electro-galvanization processes. In hot-dip galvanization, the cleaned wire is submerged in molten zinc, creating a robust protective layer. In contrast, electro-galvanization involves an electroplating process that results in a thinner zinc coating but provides a smooth finish.

The choice of manufacturing method often depends on the intended application and required durability. After galvanization, the wire is cut to specific lengths, often coiled for ease of handling. Manufacturers play a pivotal role in ensuring that the wire meets industry standards and customer specifications, which can vary widely based on the intended use.

Key Applications

galvanized binding wire manufacturers

Galvanized binding wire is utilized across numerous industries, each benefiting from its unique properties. In construction, for example, it is often used to tie rebar together, providing critical support for concrete structures. The corrosion resistance of galvanized wire ensures that it maintains its strength over time, contributing to the longevity of the construction.

In agriculture, galvanized binding wire is employed to secure fencing, support crops, and even bundle hay. Its resistance to rust is vital in outdoor environments, where exposure to moisture can lead to significant material degradation.

Moreover, in the manufacturing sector, galvanized wire is used in the production of various items, including wire mesh, baskets, and even in automotive applications. The adaptability of galvanized binding wire makes it a favored choice across diverse industrial applications.

Choosing the Right Manufacturer

The selection of a galvanized binding wire manufacturer is paramount for those seeking quality and reliability. Reputable manufacturers prioritize the use of high-grade materials and adhere to strict quality control standards. They often provide certifications to highlight their compliance with industry standards, ensuring that their products meet the necessary specifications for safety and durability.

Furthermore, established manufacturers typically offer a range of products, allowing customers to choose wire that best fits their application needs. Engaging with manufacturers that provide excellent customer service and technical support can also facilitate smoother project executions, making collaboration efficient and effective.

Conclusion

Galvanized binding wire manufacturers are crucial players in the trade and construction industries. By producing reliable and long-lasting materials, they contribute significantly to the structural integrity of buildings, the productivity of agricultural operations, and the functionality of various manufacturing processes. As industries continue to evolve, the demand for high-quality galvanized binding wire remains steadfast, underpinning the need for skilled manufacturers who can meet the diverse requirements of their clients. Understanding the layers of this industry helps stakeholders appreciate the value of galvanized binding wire not just as a product but as a fundamental component of countless applications. With ongoing advancements in manufacturing techniques and a growing emphasis on durability and sustainability, the future of galvanized binding wire certainly looks promising.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025