Aug . 19, 2024 14:28 Back to list

Galvanized Welded Wire Mesh Products from China Meeting ISO Standards for Quality

China's Galvanized Welded Wire Mesh Standards, Applications, and Benefits

Galvanized welded wire mesh has become an essential material in various industries due to its durability, versatility, and cost-effectiveness. Specifically, China's production of galvanized welded wire mesh has gained immense popularity, driven by both domestic needs and international demand. This article will explore the significance of galvanized welded wire mesh from China, focusing on its ISO standards, applications, and various advantages.

Understanding Galvanized Welded Wire Mesh

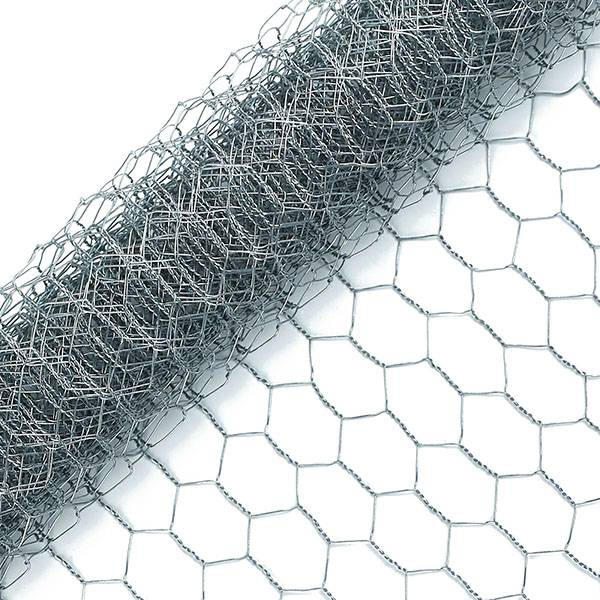

Galvanized welded wire mesh is created by welding together intersecting steel wires, which are then coated with a layer of zinc to prevent rust and corrosion. This process ensures that the mesh retains its structural integrity even in harsh environments. The zinc coating comes in two primary forms electro-galvanized and hot-dipped galvanized. The hot-dipped method offers superior protection, making it highly desirable for outdoor applications.

ISO Standards and Quality Assurance

In an increasingly global market, adherence to international standards like ISO (International Organization for Standardization) is crucial. Chinese manufacturers of galvanized welded wire mesh often comply with ISO 9001 standards, which focus on quality management systems. This certification not only assures customers of consistent product quality but also enhances the manufacturers' credibility in the global market.

ISO standards cover various aspects of production, including material selection, manufacturing processes, and testing methodologies. For instance, wire thickness, mesh size, and the tensile strength of welded joints are critical parameters that fall under these standards. By adhering to ISO guidelines, Chinese manufacturers ensure that their products can withstand different environmental stresses while meeting the specific requirements of various applications.

Diverse Applications

Galvanized welded wire mesh finds applications across multiple sectors, including construction, agriculture, industrial, and residential areas.

1. Construction and Civil Engineering This mesh is widely used for reinforcement in concrete structures, offers formwork support, and as a barrier for construction sites.

china galvanized welded wire mesh iso

3. Industrial Use The mesh is employed in creating safety barriers, storage cages, and shelving units in warehouses. Its strength and durability make it ideal for industrial applications where safety is paramount.

4. Residential Fencing Homeowners favor galvanized welded wire mesh for fencing solutions due to its long-lasting nature and low maintenance requirements.

Advantages of Using Galvanized Welded Wire Mesh

The benefits of using galvanized welded wire mesh are considerable

- Durability Thanks to the zinc coating, galvanized wire mesh is resistant to rust and corrosion, significantly prolonging its lifespan.

- Cost-Effectiveness It provides an economical solution for various applications, especially when compared to alternative materials.

- Versatility Available in different wire gauges and mesh patterns, it can be customized to suit specific needs across various sectors.

- Easy Installation The welded design allows for quick and straightforward installation, making it a favorite among contractors and DIY enthusiasts.

Conclusion

China's galvanized welded wire mesh represents a blend of traditional manufacturing skills and modern quality standards. By adhering to ISO guidelines and embracing innovation, Chinese manufacturers have positioned themselves as key players in the global market. The versatility and durability of galvanized welded wire mesh make it a favored choice across industries. As demand continues to rise, China's commitment to quality will likely drive further growth in the sector, reinforcing its reputation as one of the leading producers of galvanized welded wire mesh in the world.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025