Jul . 31, 2024 12:10 Back to list

Galvanized Welded Wire Mesh Production by ISO Certified Manufacturers for Durable Applications

The Importance of Quality in Galvanized Welded Wire Mesh Manufacturing

When it comes to construction and infrastructure, quality materials are paramount to ensuring the durability and longevity of structures. One such essential component is galvanized welded wire mesh, a versatile product widely used in various applications, including reinforcement, fencing, and landscaping. As industries evolve, the need for high-quality manufacturing processes becomes increasingly critical—especially for ISO-certified manufacturers.

What is Galvanized Welded Wire Mesh?

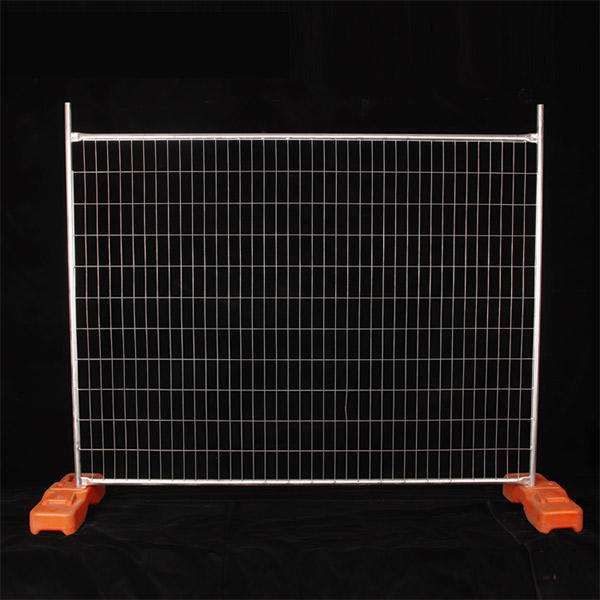

Galvanized welded wire mesh is a grid of wires that have been welded together at their intersections to create a robust structure. The galvanized aspect refers to the coating of zinc applied to the wire, which acts as a protective layer against rust and corrosion. This feature is especially valuable in environments exposed to moisture, chemicals, or other corrosive agents. The mesh is available in several sizes and gauge thicknesses, making it adaptable to numerous applications.

Advantages of Galvanized Welded Wire Mesh

1. Corrosion Resistance The primary benefit of galvanized wire mesh is its ability to resist corrosion. The zinc coating protects the steel from rust formation, ensuring that the mesh maintains its strength and integrity over time.

2. Strength and Durability Welded wire mesh is known for its tensile strength. The welding process creates a more robust connection between the wires compared to other types of mesh, such as woven wire.

3. Cost-Effectiveness Galvanized welded wire mesh offers a high-strength solution at a lower cost compared to solid metal barriers or other materials. Its longevity also reduces maintenance and replacement costs.

4. Versatility This type of mesh can be utilized in a variety of applications, including concrete reinforcement, animal enclosures, garden fencing, and even decorative purposes. Its versatility makes it a popular choice across multiple industries.

galvanized welded wire mesh iso manufacturer

The Role of ISO Certification

ISO (International Organization for Standardization) certification represents an internationally recognized standard of quality management. Manufacturers of galvanized welded wire mesh that achieve ISO certification demonstrate a commitment to maintaining high-quality production processes and products. Benefits of working with ISO-certified manufacturers include

1. Consistent Quality ISO-certified manufacturers adhere to stringent quality control procedures, ensuring that every batch of wire mesh produced meets specific standards.

2. Customer Confidence Buyers can trust that ISO-certified products are reliable and safe to use. This helps build a solid reputation for manufacturers and increases customer loyalty.

3. Continuous Improvement ISO certification requires ongoing evaluation and improvement of processes and systems. This commitment to innovation helps manufacturers stay competitive in a rapidly evolving marketplace.

4. Global Reach ISO certification is recognized worldwide, allowing manufacturers to expand their market reach and cater to international clients.

Conclusion

The significance of galvanized welded wire mesh cannot be understated, especially in today's construction and infrastructure climate where quality and durability are necessary. Companies seeking reliable materials should prioritize working with ISO-certified manufacturers to ensure they acquire high-quality products that will serve their intended purpose effectively. As industries continue to evolve and grow, the demand for superior galvanized welded wire mesh will undoubtedly increase, underscoring the importance of quality manufacturing practices in our modern world.

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025