Dec . 04, 2024 09:32 Back to list

Galvanized Welded Wire Mesh Production and Quality Assurance by Leading Manufacturers

Understanding Galvanised Welded Wire Mesh A Comprehensive Overview

In the realm of construction and fencing, materials play a crucial role in determining the strength, durability, and effectiveness of a project. One material that stands out for its versatility and resilience is galvanised welded wire mesh. This article explores what galvanised welded wire mesh is, its manufacturing process, benefits, applications, and why choosing the right manufacturer is essential.

What is Galvanised Welded Wire Mesh?

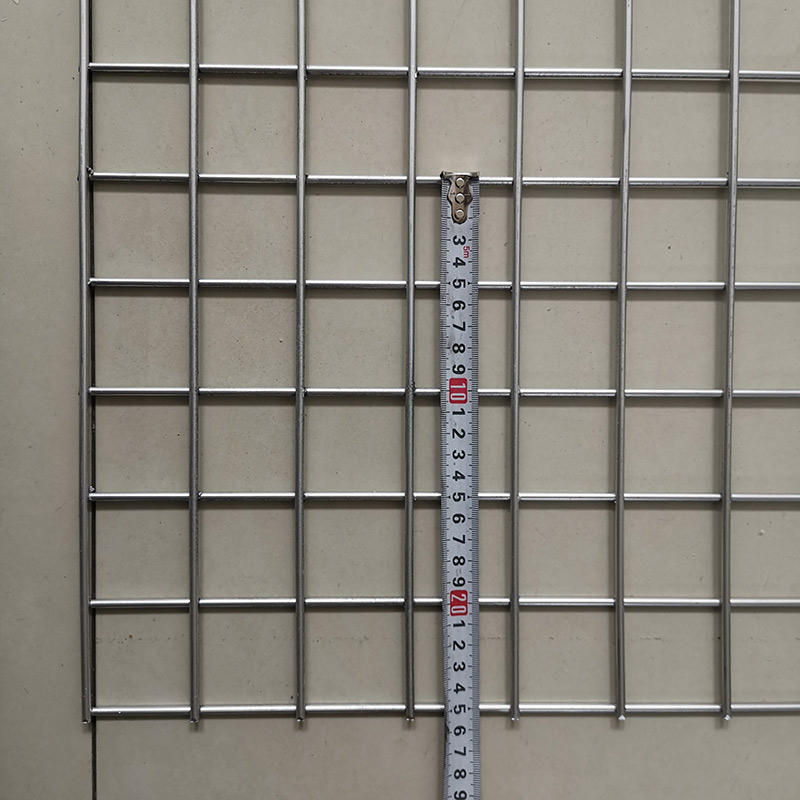

Galvanised welded wire mesh is a type of wire mesh made from high-tensile, strong steel wires that are welded together at their intersections to form a stable grid pattern. The term “galvanised” refers to the process of coating the wire with a layer of zinc. This coating serves two primary purposes it protects the steel from rust and corrosion, and it increases the overall lifespan of the wire mesh itself.

The welded wire mesh is typically available in various sizes, wire gauges, and mesh openings, allowing for extensive customization based on specific project requirements. Its applications range from fencing and security to construction and agriculture.

The Manufacturing Process

The manufacturing of galvanised welded wire mesh involves several steps

1. Wire Drawing Steel rods are drawn through dies to produce wire of the desired gauge. The drawing process enables manufacturers to refine the wire’s diameter and enhance its tensile strength.

2. Welding The prepared wires are arranged in a grid pattern and then welded at their intersections using electric resistance welding. This step ensures that the mesh has uniform strength and a high degree of integrity.

3. Galvanisation After welding, the mesh is subjected to a galvanisation process, which can be conducted through either hot-dip galvanisation or electro-galvanisation. Hot-dip galvanisation involves immersing the welded wire mesh in molten zinc, creating a thick and durable coating. Electro-galvanisation, on the other hand, applies a thinner layer of zinc through an electrochemical process.

4. Finishing and Inspection Following galvanisation, the mesh is cleaned, cut to size, and inspected for quality control. Manufacturers often conduct tests to ensure that the mesh meets industry standards for tensile strength and corrosion resistance.

Benefits of Galvanised Welded Wire Mesh

1. Durability The zinc coating significantly enhances the mesh's resistance to rust and corrosion, making it ideal for outdoor applications.

3. Low Maintenance Unlike other fencing materials, galvanised welded wire mesh requires minimal maintenance and has a long service life.

4. Versatility Its adaptability makes it suitable for various applications, including garden fencing, animal enclosures, construction reinforcement, and industrial uses.

galvanised welded wire mesh manufacturer

5. Cost-Effectiveness Given its longevity and low maintenance requirements, galvanised welded wire mesh is a cost-effective solution in the long term.

Applications of Galvanised Welded Wire Mesh

Galvanised welded wire mesh is utilized across numerous industries

- Construction In construction, it is often used as reinforcement for concrete structures such as slabs, walls, and beams.

- Fencing The mesh is widely employed for agricultural fencing, residential fencing, and security fencing around commercial properties due to its strength and visibility.

- Industrial In industrial settings, it is used in the creation of cages, barriers, and partitions, as well as for ventilation and safety applications.

- Agriculture Farmers use it for animal enclosures, poultry housing, and crop protection against pests.

Choosing the Right Manufacturer

When looking for a galvanised welded wire mesh manufacturer, consider the following factors

1. Quality and Standards Ensure the manufacturer adheres to international quality standards and conducts rigorous inspections.

2. Customization Options A good manufacturer should offer customizable solutions tailored to your specific requirements.

3. Experience and Reputation Opt for companies with a solid track record and positive reviews in the industry.

4. Customer Support Quality customer service is imperative for addressing inquiries and issues that may arise.

5. Pricing Evaluate pricing compared to the quality offered to ensure you are making a financially sound decision.

Conclusion

Galvanised welded wire mesh is an invaluable material in various applications due to its strength, durability, and versatility. Understanding the manufacturing process and benefits can help in selecting the right product for your needs. Moreover, choosing a reputable manufacturer is crucial for ensuring that you receive a high-quality product that meets your specifications and will stand the test of time. Whether for fencing, construction, or agricultural uses, investing in galvanised welded wire mesh is a decision that continues to pay off with lasting performances.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025