Nov . 11, 2024 14:05 Back to list

galvanised chain link fence manufacturers

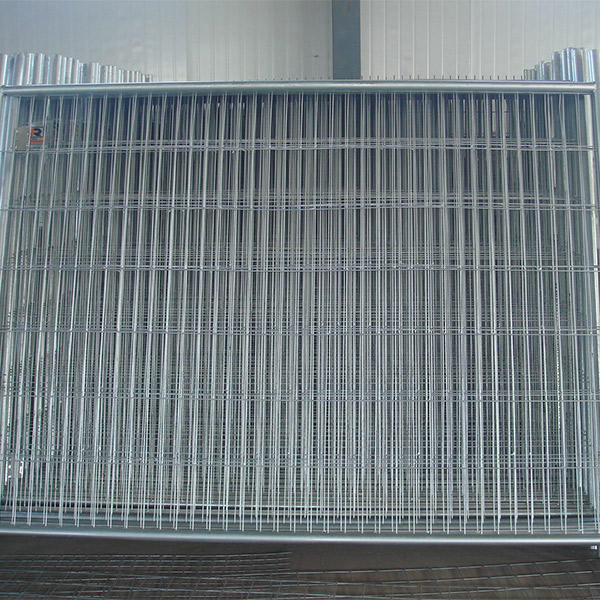

Understanding Galvanized Chain Link Fence Manufacturers

Chain link fences are a popular choice for residential, commercial, and industrial properties due to their durability, cost-effectiveness, and versatile applications. Among the various types of chain link fences available, galvanized chain link fences are among the most sought after. Manufactured using steel coated in zinc, these fences are resistant to rust and corrosion, making them an ideal choice for various environmental conditions. In this article, we will delve into the world of galvanized chain link fence manufacturers, exploring their importance, manufacturing process, and the benefits of selecting high-quality products.

The Significance of Galvanized Chain Link Fences

Galvanized chain link fences serve a multitude of purposes, from security and property delineation to aesthetic enhancement. They are commonly used in residential backyards, parks, sports facilities, and commercial properties to provide a secure barrier without obstructing the view. The galvanized coating not only enhances the lifespan of the fence but also minimizes maintenance requirements, making it an economical option for long-term use.

The Manufacturing Process

The manufacturing of galvanized chain link fences involves several stages, starting from the selection of raw materials to the final production and installation. Here’s a brief overview of the manufacturing process

1. Material Selection High-quality steel is the primary raw material used in the production of chain link fences. The steel wire is selected for its strength and flexibility, ensuring durability and effectiveness.

2. Wire Coating The steel wire undergoes a galvanization process, where it is coated with zinc. This process can be performed through two main methods hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing involves immersing the wire in molten zinc, creating a thick, protective coating. Electro-galvanizing uses an electrochemical process to apply zinc, resulting in a thinner layer but offering a decent level of protection.

3. Weaving and Cutting Once the wire has been coated, it is woven into a mesh pattern, forming the actual chain link fabric. The links are then cut to the desired heights and widths, depending on the specifications given by the customer.

4. Framework Production The next step involves creating the fence framework, which consists of posts and rails. These components are typically made from galvanized steel as well, ensuring the entire structure is resistant to rust and corrosion.

galvanised chain link fence manufacturers

5. Assembly and Installation Finally, the chain link fabric is attached to the framework. This can be done using tension bands and wire ties to securely fasten the fabric to the posts. Manufacturers might also offer installation services, ensuring a proper setup that meets the safety standards and customer expectations.

Choosing the Right Manufacturer

When it comes to selecting a manufacturer for galvanized chain link fences, it is essential to consider several factors

1. Quality of Materials Ensure that the manufacturer uses high-grade steel and zinc for galvanization, as this directly impacts the durability and longevity of the fence.

2. Experience and Reputation Look for manufacturers with a proven track record in the industry. A company’s reputation can provide insights into the quality of its products and customer service.

3. Customization Options Different projects have varying requirements. A reputable manufacturer should offer customization options, allowing you to choose the height, gauge of wire, and type of finish for your fence.

4. Warranty and Support A manufacturer that provides a warranty on its products indicates confidence in their quality. Additionally, good customer support can make a significant difference in case any issues arise during installation or later use.

5. Sustainability Practices With growing environmental concerns, consider a manufacturer that employs sustainable practices in their production process, ensuring minimal impact on the environment.

Conclusion

Galvanized chain link fences represent a reliable and cost-effective solution for a variety of fencing needs. By understanding the manufacturing process and the importance of selecting a reputable manufacturer, consumers can ensure that they invest in quality products that will serve them well for years to come. Whether for residential use or industrial applications, a well-made galvanized chain link fence provides security, functionality, and peace of mind.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025