Nov . 14, 2024 12:56 Back to list

galvanised chain link fence factories

The Rise of Galvanised Chain Link Fence Factories An Industry Evolution

In the modern era of construction and security, chain link fences have become a ubiquitous choice for both residential and commercial properties. One of the most efficient and durable options available on the market today is the galvanised chain link fence. This type of fencing provides a perfect blend of strength, durability, and cost-effectiveness. As demand for these versatile fencing solutions continues to grow, galvanised chain link fence factories are becoming more prominent, revolutionizing the industry by leveraging advanced manufacturing techniques and meeting the needs of a diverse clientele.

Understanding Galvanisation

Galvanisation is the process of applying a protective zinc coating to steel or iron to prevent rusting. The galvanised chain link fence is manufactured by weaving steel wire into a diamond pattern, which is then coated in zinc. This protective layer not only enhances the fence's sturdiness but also extends its lifespan, making it suitable for both commercial use and residential applications. As a result, galvanised chain link fences are often chosen for various purposes, including security for properties, enclosures for sports facilities, and barriers for construction sites.

The Manufacturing Process

The factory manufacturing galvanised chain link fences typically follows a systematic process that begins with selecting high-quality steel wire. The wire is then drawn down to the required gauge before being woven into a chain link fabric. Subsequently, this fabric goes through the galvanisation process, where it is either hot-dipped or electro-galvanised, ensuring a robust zinc coating that will withstand environmental stressors.

In addition to fabric production, factories also focus on creating various components that accompany the fencing, such as posts, rails, and fittings. These elements are critical for the overall integrity of the fence, as they provide stabilisation and support. High-tech machinery and automated systems are increasingly employed in galvanised chain link fence factories, which not only bolster efficiency but also improves the quality control process. This evolution towards automation aligns with global manufacturing trends, enhancing output while minimizing human error.

Meeting Diverse Needs

galvanised chain link fence factories

The versatility of galvanised chain link fences has positioned factories to cater to a wide range of customers. From industrial applications to securing schools and parks, these fences provide a robust solution that fits varying needs. Additionally, factories often offer customization options, allowing customers to select specific heights, gauges, and finishes according to their preferences.

Moreover, the growing awareness of environmental sustainability has led many factories to adopt eco-friendly practices. Advanced galvanisation methods reduce waste and emissions, which appeals to environmentally conscious consumers. Businesses are increasingly scrutinizing their suppliers and shifting towards products that offer both functionality and sustainability.

Challenges and Innovations

Despite the growth and advancements in galvanised chain link fence production, the industry faces several challenges. Fluctuating raw material prices, particularly for steel, can impact manufacturing costs. Similarly, the competition from alternative fencing solutions, such as vinyl and wood, necessitates ongoing innovation and product differentiation.

To address these challenges, galvanised chain link fence factories are investing in research and development. Innovations include improved galvanisation techniques that enhance durability and resistance to corrosion. The incorporation of technology for better design and efficiency also plays a crucial role. Factories that adapt to these changes—by adopting Lean Manufacturing principles, for example—will be better positioned to succeed.

Conclusion

As the demand for reliable and cost-effective fencing solutions continues to rise, galvanised chain link fence factories play an essential role in meeting this need. By utilising advanced manufacturing processes and innovative practices, these factories are not only catering to a diverse clientele but are also paving the way for sustainable practices within the industry. With ongoing advancements and a focus on quality, galvanised chain link fences are likely to remain a staple in construction and security for years to come. As factories adapt and evolve, they contribute significantly to shaping the future landscape of fencing solutions, poised to meet the ever-changing demands of consumers.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

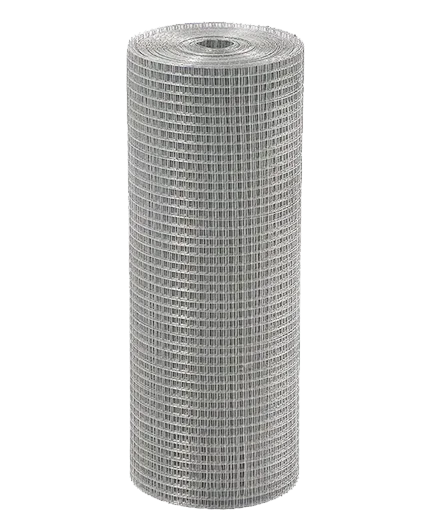

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025