Sep . 19, 2024 20:16 Back to list

galvanised heavy-gauge welded wire mesh manufacturers

The Importance of Galvanized Heavy-Gauge Welded Wire Mesh in Various Industries

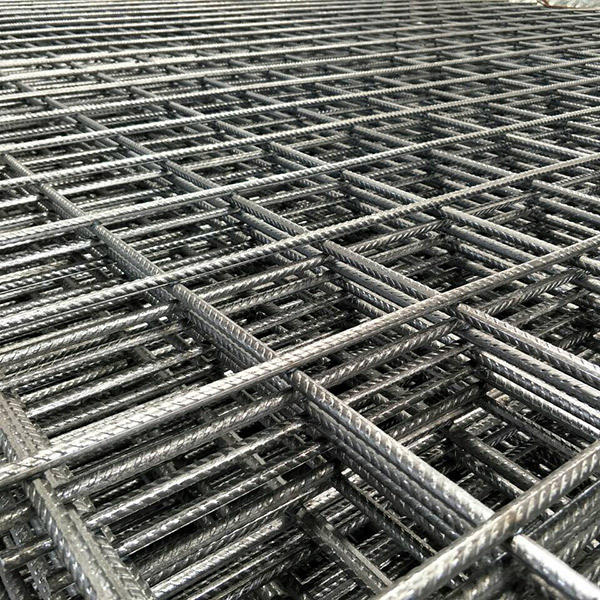

In today’s rapidly evolving industries, the need for robust and reliable materials is paramount. Among various construction and manufacturing solutions, galvanized heavy-gauge welded wire mesh stands out as a superior choice due to its strength, durability, and versatility. This article explores the significance of this material, its manufacturing process, applications, and benefits, particularly highlighting leading manufacturers in the field.

Understanding Galvanized Heavy-Gauge Welded Wire Mesh

Galvanized welded wire mesh is produced by welding wires together at their intersections, creating a grid-like structure. The heavy-gauge aspect indicates that the wire used is of a thicker diameter, contributing to enhanced strength and stability. The galvanization process involves coating the steel wires with a layer of zinc to protect against corrosion, making this type of wire mesh suitable for outdoor and harsh environments.

Manufacturing Process

The manufacturing of galvanized heavy-gauge welded wire mesh involves several steps. First, high-quality steel wires are drawn to the desired thickness and then are cut to the required lengths. These wires are then arranged in a grid pattern and welded together at the intersections using advanced welding techniques. After welding, the mesh is subjected to a galvanization process where it is dipped in molten zinc. This protective layer not only enhances the mesh's resistance to rust but also extends its lifespan significantly compared to non-galvanized alternatives.

Applications

The applications of galvanized heavy-gauge welded wire mesh are extensive and diverse. One of the primary uses is in construction, where it serves as reinforcement for concrete, ensuring structural integrity. Additionally, it is widely used in fencing solutions for both industrial and agricultural purposes, providing security and containment for livestock and crops.

galvanised heavy-gauge welded wire mesh manufacturers

Moreover, this type of wire mesh is utilized in various other industries, including automotive, manufacturing, and environmental projects. For instance, in the manufacturing sector, it is employed in the production of products like shelves, cages, and partitions. In environmental applications, it is used in erosion control and landscaping projects, where it assists in soil stabilization.

Benefits of Galvanized Heavy-Gauge Welded Wire Mesh

The advantages of this material are manifold. Firstly, its robust construction ensures long-lasting performance, making it an excellent investment for various projects. The galvanization process grants it outstanding corrosion resistance, allowing for outdoor use without compromising durability. Furthermore, the heavy-gauge nature of the wire mesh provides additional strength, making it capable of withstanding heavy loads and impact.

Additionally, galvanized heavy-gauge welded wire mesh is easy to install and can be customized to meet specific project requirements. Manufacturers offer a range of sizes and configurations, ensuring versatility and adaptability for different applications.

Leading Manufacturers

There are numerous manufacturers around the globe specializing in galvanized heavy-gauge welded wire mesh, known for their commitment to quality and innovation. Companies such as WireMesh Industries, Texas Wire Products, and Roman Steel are recognized for their high-quality products and reliable customer service. They employ state-of-the-art technology in their manufacturing processes, ensuring consistency and precision in their wire mesh solutions.

Conclusion

In conclusion, galvanized heavy-gauge welded wire mesh emerges as a vital component across multiple industries, driven by its strength, durability, and versatility. With continued advancements in manufacturing and an extensive range of applications, this material is likely to remain a staple in construction, agriculture, and beyond. Investing in quality galvanized wire mesh from reputable manufacturers not only ensures superior performance but also contributes to the longevity and success of various projects.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025