Nov . 27, 2024 07:58 Back to list

Welded Wire Mesh Production in Gabion Manufacturing Facilities

The Significance of Gabion Welded Wire Mesh Factories in Modern Infrastructure

In today's rapidly evolving construction landscape, the demand for durable, cost-effective, and sustainable materials has never been higher. Gabion welded wire mesh has emerged as a vital component in various civil engineering projects, ranging from landscaping to heavy-duty infrastructure. With its robust design and versatility, the manufacturing of gabion welded wire mesh has become a significant industry, playing an essential role in constructing environmentally-friendly solutions.

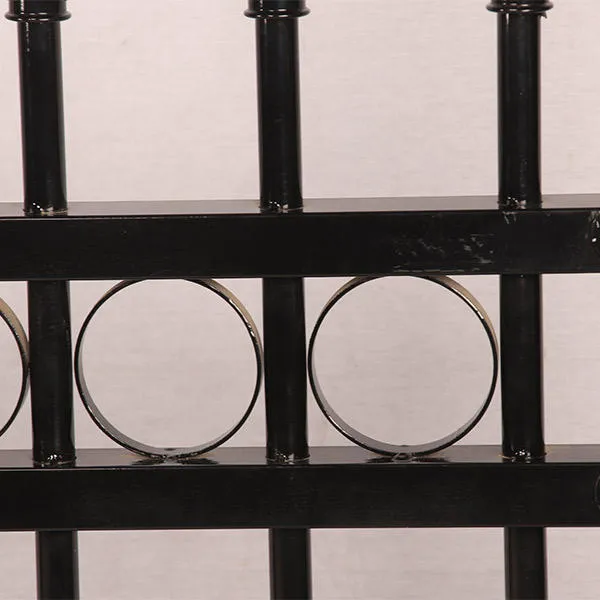

Gabions, which are wire mesh containers filled with rocks or other materials, have been utilized for centuries. However, the advent of welded wire mesh technology has revolutionized their application. Unlike traditional gabions made from woven wire, welded wire mesh provides superior strength, ensuring that structures remain intact even under heavy stress and adverse environmental conditions. Factories specializing in the production of gabion welded wire mesh utilize advanced techniques and equipment, which enhance the quality and durability of the final product.

One of the primary advantages of gabion welded wire mesh is its versatility. This material can be used in a multitude of applications, including retaining walls, erosion control, and riverbank stabilization. As more urban areas face the challenges of flooding and soil erosion, gabion structures constructed with welded wire mesh are increasingly employed to protect vulnerable landscapes and enhance the resilience of built environments. The ability of gabions to blend seamlessly into their surroundings also makes them an attractive option for landscape architects and designers.

Moreover, the manufacturing process of gabion welded wire mesh is designed to be efficient and environmentally friendly. Modern factories focus on using sustainable materials and processes, minimizing waste while maximizing output. Many manufacturing plants have adopted energy-efficient technologies, reducing their carbon footprint while maintaining high production standards. This commitment to sustainability is critical in an age where environmental considerations play a crucial role in construction and development.

gabion welded wire mesh factories

The demand for gabion welded wire mesh is not limited to domestic markets; it extends globally. As countries around the world face challenges related to climate change and urbanization, the need for effective erosion control and infrastructure support continues to grow. Internationally, factories have expanded their operations to meet this demand, establishing strong supply chains that ensure quick delivery and competitive pricing. This globalization of gabion welded wire mesh production has not only increased accessibility but has also fostered innovation as factories strive to improve their products and technologies in response to global market needs.

A significant factor contributing to the efficiency of gabion welded wire mesh factories is the automation of production processes. With advancements in technology, the industry has seen a shift toward automated systems that enhance precision and consistency. This transition not only boosts productivity but also improves safety and reduces the likelihood of human error. Automated welding machines and computer-aided design (CAD) software enable manufacturers to produce high-quality mesh at a faster rate, catering to the growing demands of the construction sector.

In addition, the rise of e-commerce has transformed how gabion welded wire mesh is marketed and sold. Manufacturers can now reach a broader audience, allowing contractors and builders to purchase directly from producers, which streamlines the purchasing process and often reduces costs. Online platforms provide detailed product specifications, enabling customers to make informed decisions that best suit their project requirements.

Ultimately, gabion welded wire mesh factories are pivotal in addressing contemporary construction challenges. By prioritizing strength, durability, and environmental sustainability, these factories are not only providing essential materials for infrastructure development but also contributing to a more sustainable future. As the industry continues to evolve, the role of innovative manufacturing techniques and global collaboration will undoubtedly play a crucial part in shaping the next generation of gabion solutions, ensuring they remain an integral component of modern construction and landscaping projects.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025